Check out the leading manufacturer for professional coil packing solutions here:

Robotic Palletizing: Revolutionizing Warehouse Operations

Introduction:

In today’s fast-paced world, businesses are constantly seeking innovative solutions to optimize their operations and increase efficiency. One such solution gaining popularity is Robotic Palletizing. This cutting-edge technology is revolutionizing the way warehouses handle packaging and palletizing tasks. In this article, we will explore the benefits and capabilities of Robotic Palletizing, with a focus on the Robotic Stretch Wrapper.

Robotic Stretch Wrapper: Enhancing Efficiency and Productivity

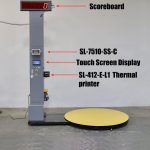

The Robotic Stretch Wrapper is an integral part of the Robotic Palletizing system. It is designed to automate the process of wrapping pallets with stretch film, ensuring secure and stable shipping. This technology offers several advantages over traditional manual wrapping methods.

1. Increased Efficiency: The Robotic Stretch Wrapper eliminates the need for manual labor, allowing for faster and more consistent wrapping of pallets. With its high-speed capabilities, it can wrap multiple pallets in a fraction of the time it would take a human operator.

2. Improved Safety: Manual wrapping can be physically demanding and potentially hazardous. By automating the wrapping process, the Robotic Stretch Wrapper reduces the risk of injuries, providing a safer working environment for employees.

3. Consistent and Precise Wrapping: The Robotic Stretch Wrapper ensures uniform tension and wrapping integrity, resulting in securely wrapped pallets that are less prone to damage during transportation. This consistency translates into cost savings as it reduces the risk of product loss or damage.

Robotic Case Palletizing and Stretch Wrapper System: A Winning Combination

To further enhance efficiency and productivity, Kaufman Engineered Systems offers a Robotic Case Palletizing and Stretch Wrapper System. This integrated solution combines the capabilities of a Robotic Palletizer with a Robotic Stretch Wrapper, providing a seamless and comprehensive palletizing and wrapping process.

1. Streamlined Operations: The Robotic Case Palletizing and Stretch Wrapper System eliminates the need for separate equipment and manual intervention. It automates the entire palletizing and wrapping process, reducing downtime and optimizing workflow.

2. Flexibility and Versatility: This system can handle a wide range of products, sizes, and packaging configurations. From cases to cartons, the Robotic Case Palletizing and Stretch Wrapper System can adapt to various packaging requirements, offering versatility to businesses across industries.

3. Increased Cost Savings: By automating palletizing and wrapping tasks, businesses can reduce labor costs and minimize product loss or damage. The system’s efficiency and precision contribute to overall cost savings, making it a valuable investment for any warehouse operation.

Conclusion:

Robotic Palletizing, coupled with the Robotic Stretch Wrapper, is transforming the way warehouses handle packaging and palletizing tasks. With increased efficiency, improved safety, and consistent wrapping, this technology offers numerous benefits to businesses seeking to optimize their operations.

If you are looking for a leading manufacturer of coil packing solutions, look no further. Visit our website to explore the range of professional solutions available to enhance your packaging and palletizing processes. Stretch Wrapping Machine

“Efficient Robotic Case Palletizing and Stretch Wrapping System Unveiled: A Game-Changer in Packaging Automation”