Check out the leading manufacturer for a professional coil packing solution here: [link]

Best Filling Packing Machine: Revolutionizing the Packaging Industry

In today’s fast-paced world, efficient and reliable packaging solutions are essential for businesses to stay competitive. One such solution that has been gaining popularity is the Best Filling Packing Machine. This state-of-the-art machine offers a range of benefits, from increased productivity to improved product quality. In this article, we will delve into the features, advantages, and applications of the Best Filling Packing Machine, providing you with a comprehensive understanding of this innovative technology.

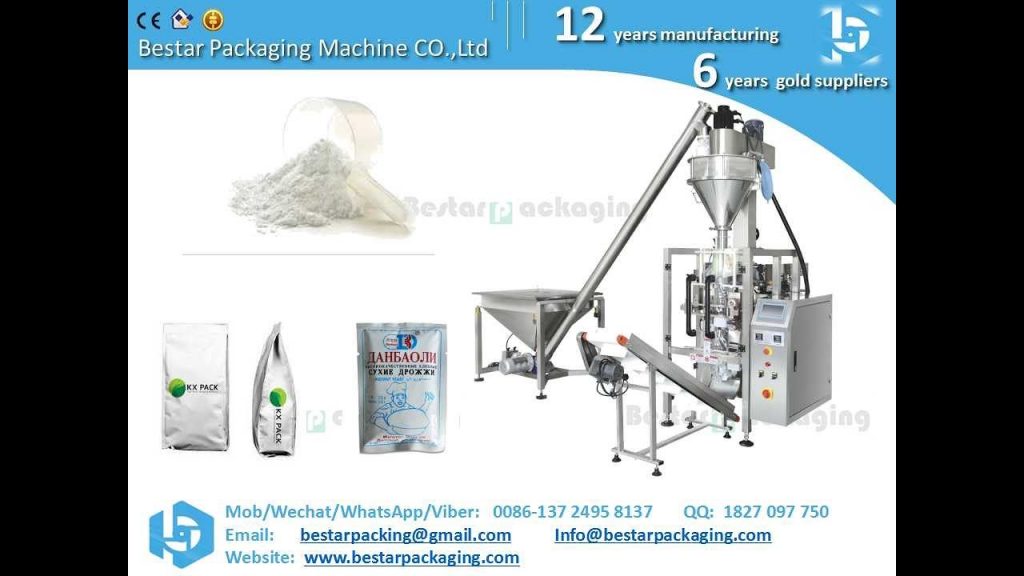

The Best Filling Packing Machine is an automatic powder filling and packing machine that is designed to streamline the packaging process. With its cutting-edge technology and user-friendly interface, it offers a seamless and efficient solution for businesses in various industries. This machine is capable of filling and packing a wide range of products, including powdered substances, guest bags, and 4-side seal pouches. Its versatility makes it an ideal choice for manufacturers looking to enhance their packaging capabilities.

One of the standout features of the Best Filling Packing Machine is its high-speed performance. With a capacity of up to [insert capacity], it can handle large volumes of products in a short amount of time. This not only saves precious production hours but also ensures consistent and accurate packaging. The machine’s precision ensures that each package is filled to the desired weight, eliminating the risk of under or overfilling. This not only enhances product quality but also reduces material wastage, resulting in significant cost savings for businesses.

The Best Filling Packing Machine also boasts advanced technology that guarantees the integrity of the packaging. Its 4-side seal pouch making capability ensures that the products are securely sealed, protecting them from moisture, contaminants, and other external factors. This is particularly crucial for industries such as food and pharmaceuticals, where product safety and hygiene are of utmost importance. Additionally, the machine’s automatic detection and rejection system minimize the risk of faulty packaging, further enhancing product quality and customer satisfaction.

Furthermore, the Best Filling Packing Machine is designed with user convenience in mind. Its intuitive interface and customizable settings allow operators to easily adjust the machine according to their specific requirements. The machine is also equipped with intelligent sensors and alarms that alert operators of any potential issues, minimizing downtime and maximizing productivity. Its compact design and easy-to-clean components make maintenance hassle-free, ensuring that the machine operates at peak performance at all times.

The applications of the Best Filling Packing Machine are vast and varied. It is widely used in industries such as food and beverage, pharmaceuticals, chemicals, and cosmetics. Whether it’s filling and packing spices, coffee, protein powder, or pharmaceutical capsules, this machine offers a reliable and efficient solution. Its versatility and adaptability make it an indispensable asset for businesses of all sizes.

In conclusion, the Best Filling Packing Machine is a game-changer in the packaging industry. Its advanced features, high-speed performance, and user-friendly interface make it the go-to choice for manufacturers looking to optimize their packaging process. With its ability to handle a wide range of products and ensure precision and quality, this machine is revolutionizing the way businesses package their products. So, if you’re in the market for a reliable and efficient packaging solution, look no further than the Best Filling Packing Machine.

Check out the leading manufacturer for a professional coil packing solution here: [link] Filling Packing Machine

“Efficient Powder Filling & Packing Machines for Various Packaging Needs”