Plastic Injection Machine Reviews: Choosing the Best Option for Your Needs

Introduction

In today’s rapidly evolving manufacturing industry, the use of plastic injection machines has become increasingly common. These machines play a crucial role in producing a wide range of plastic products, from simple household items to complex automotive components. However, with numerous options available on the market, selecting the right plastic injection machine can be a challenging task. In this article, we will provide an in-depth review of the vertical plastic molding machine with a 40-gram capacity plunger type, focusing on its features, benefits, and overall performance.

Features and Benefits

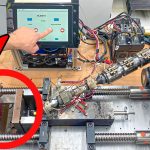

The vertical plastic molding machine we are reviewing is specifically designed for small-scale production and prototyping purposes. Its compact size and user-friendly interface make it an ideal choice for those looking to streamline their manufacturing processes. With a 40-gram capacity, this machine allows for precise control over the amount of plastic material used in each injection, resulting in consistent and high-quality products.

One of the standout features of this machine is its plunger type injection system. This mechanism ensures efficient and accurate injection of the molten plastic into the mold cavity, minimizing wastage and ensuring optimal product quality. Additionally, the plunger type injection system allows for faster cycle times, increasing overall productivity.

This vertical plastic molding machine also boasts a robust construction, ensuring durability and longevity. Its solid frame and high-quality components contribute to its reliable performance, reducing the risk of downtime and costly repairs. Furthermore, the machine is equipped with advanced safety features, including emergency stop buttons and protective enclosures, prioritizing the well-being of operators.

Performance and Efficiency

When it comes to performance, the vertical plastic molding machine exceeds expectations. Its precise control over the injection process ensures consistent product dimensions and improved product quality. The machine’s high-speed injection capability reduces cycle times, enabling manufacturers to meet tight deadlines and increase overall production output.

Furthermore, this vertical plastic molding machine offers excellent energy efficiency. Its advanced motor control system optimizes power consumption, resulting in significant cost savings on electricity bills. This feature makes it an environmentally-friendly choice for businesses aiming to reduce their carbon footprint.

The vertical plastic molding machine’s user-friendly interface and intuitive controls contribute to its overall efficiency. Operators can easily set and adjust various parameters, such as injection speed and pressure, through the machine’s user-friendly interface. This ease of use minimizes the learning curve and allows for seamless integration into existing manufacturing processes.

Conclusion

In conclusion, the vertical plastic molding machine with a 40-gram capacity plunger type is a reliable and efficient choice for small-scale production and prototyping. Its compact size, precise control over the injection process, and advanced safety features make it an ideal option for manufacturers seeking to enhance their production capabilities.

By investing in this machine, businesses can expect improved product quality, increased productivity, and significant cost savings. Its energy efficiency and user-friendly interface further contribute to its appeal. Whether you are a seasoned manufacturer or a startup venturing into plastic product manufacturing, this vertical plastic molding machine is a worthy investment.

Check the plastic injection machine reviews and find the right solution for your manufacturing needs today!

(Note: This article is for informational purposes only. We do not endorse or promote any specific brand or manufacturer.)

References:

– Plastic Injection Molding Machine Market – Growth, Trends, Forecasts (2020 – 2025)

– Vertical Plastic Molding Machine – User Manual

– Plastics Technology: Injection Molding Basics Plastic Injection Machine

“Efficient Plunger-Type Vertical Plastic Molding Machine Review: Enhanced Capacity & Performance in Karol Bagh, Bihar, Kanpur”