Check the coil packing solution with leading manufacturer for the professional solution just here:

Title: Revolutionizing Plastic Injection Molding with Industrial Plastic Injection Machines

Introduction:

In today’s fast-paced manufacturing industry, Industrial Plastic Injection Machines have become the backbone of production processes. These machines have revolutionized the way plastic products are created, providing efficiency, precision, and versatility like never before. This article delves into the world of Industrial Plastic Injection Machines, exploring their impact on the molding industry, troubleshooting techniques, and the benefits they bring to manufacturers.

Section 1: The Power of Industrial Plastic Injection Machines

Industrial Plastic Injection Machines have transformed the manufacturing landscape by allowing manufacturers to efficiently produce high-quality plastic products. These machines combine cutting-edge technology with precision engineering to ensure accurate and repeatable molding cycles. With their ability to handle large volumes of materials, they have become an essential tool in various industries, including automotive, consumer goods, electronics, and more.

Section 2: Understanding Injection Molding Machines and Cycles

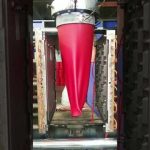

To fully comprehend the capabilities of Industrial Plastic Injection Machines, it is essential to understand the injection molding process. Injection molding involves injecting molten plastic into a mold cavity, allowing it to cool and solidify into the desired shape. The injection molding machine plays a crucial role in this process, controlling the temperature, pressure, and cycle times to ensure consistent and accurate results. By optimizing these parameters, manufacturers can achieve high productivity and minimize defects.

Section 3: Troubleshooting Techniques for Injection Molding

Despite the precision and reliability of Industrial Plastic Injection Machines, occasional issues may arise during the molding process. Understanding common troubleshooting techniques can help manufacturers identify and rectify problems efficiently. From addressing mold defects to resolving material flow issues, this section provides valuable insights into troubleshooting techniques, ensuring smooth production processes and minimizing downtime.

Section 4: The Benefits of Industrial Plastic Injection Machines

Industrial Plastic Injection Machines offer numerous advantages to manufacturers. Their precision and repeatability result in high-quality products with minimal waste. They also allow for quick mold changes, reducing production downtime and enabling faster time-to-market. Additionally, these machines offer versatility, accommodating a wide range of plastic materials, additives, and colors. This flexibility allows manufacturers to meet diverse customer requirements and stay ahead of the competition.

Section 5: Conclusion

Industrial Plastic Injection Machines have truly revolutionized the plastic molding industry, offering unparalleled efficiency, precision, and versatility. As manufacturers strive to meet increasing customer demands, these machines play a pivotal role in ensuring high-quality products and streamlined production processes. By harnessing the power of Industrial Plastic Injection Machines, manufacturers can stay ahead in today’s competitive market.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant link here] Plastic Injection Machine

“Mastering the Art of Plastic Injection Molding: Unlocking the Potential of Industrial Injection Machines”