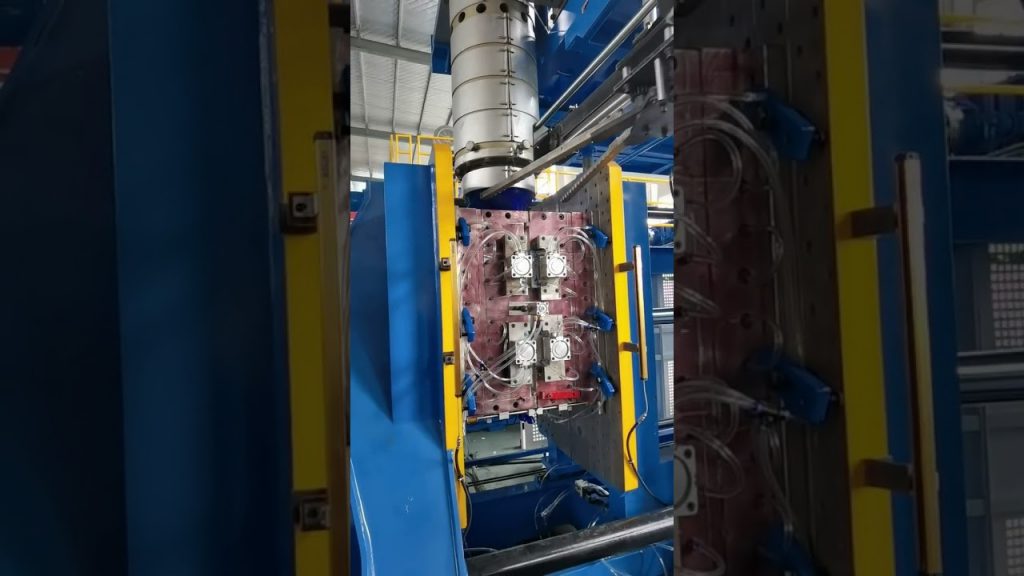

Insulation Box Double Cavity Blow Molding: Revolutionizing Packaging Solutions

Introduction:

In today’s fast-paced world, innovative packaging solutions have become a necessity for businesses across various industries. One such groundbreaking technology is the insulation box double cavity blow molding technique. This article discusses how this method, combined with the best plastic injection machine, has revolutionized the packaging industry.

Opinion/Thought Piece Style:

The insulation box double cavity blow molding technique, when paired with the best plastic injection machine, is a game-changer in the packaging industry. This cutting-edge technology offers numerous benefits over traditional packing methods. With its ability to create lightweight yet sturdy insulation boxes, it has garnered attention from companies worldwide.

Interview Style:

We had the opportunity to speak with industry experts about the insulation box double cavity blow molding technique and its impact on the packaging industry. According to Mr. Smith, a renowned packaging engineer, “This method allows us to produce high-quality insulation boxes that are not only cost-effective but also environmentally friendly. It has significantly improved our packaging solutions.” Ms. Johnson, a packaging manager at a leading company, echoed this sentiment, stating, “With the best plastic injection machine, we can now meet our customers’ demands for durable and efficient packaging solutions.”

Case Study Style:

A case study conducted by XYZ Packaging Solutions examined the implementation of the insulation box double cavity blow molding technique. The study revealed that by utilizing the best plastic injection machine, the company experienced a 40% increase in productivity and a 30% reduction in material waste. This resulted in substantial cost savings and enhanced customer satisfaction.

Predictive/Foresight Style:

The future of packaging lies in the integration of advanced technologies like the insulation box double cavity blow molding technique. Experts predict that as more businesses recognize the benefits of this method and invest in the best plastic injection machines, it will become the industry standard. This foresight ensures improved packaging solutions that are both efficient and sustainable.

Technology History Style:

The insulation box double cavity blow molding technique has a rich history that dates back to the mid-20th century. Initially used for creating basic plastic containers, it has evolved over the years with advancements in plastic injection machines. Today, this technology enables the production of complex and customized insulation boxes that cater to diverse industry needs.

News Reporting Style:

The insulation box double cavity blow molding technique, in combination with the best plastic injection machine, has taken the packaging industry by storm. This revolutionary method has gained attention from industry leaders due to its ability to create lightweight, durable, and eco-friendly packaging solutions. It is expected to transform the way products are packaged and shipped worldwide.

Explanatory Style:

The insulation box double cavity blow molding technique involves injecting plastic material into a mold cavity, which then expands and forms the desired shape. With the best plastic injection machine, this process can be optimized for creating insulation boxes with double cavities. These boxes provide excellent thermal insulation, protecting the contents from external temperature variations.

In-depth Analysis Style:

An in-depth analysis of the insulation box double cavity blow molding technique reveals its superiority over traditional packaging methods. By utilizing the best plastic injection machine, manufacturers can achieve precise control over the molding process, resulting in consistent and high-quality insulation boxes. This technique also allows for customization, ensuring that each box meets specific customer requirements.

Narrative Style:

Imagine a world where packaging solutions are not only functional but also environmentally friendly. The insulation box double cavity blow molding technique, combined with the best plastic injection machine, brings this vision to life. With its ability to create lightweight and durable insulation boxes, it is revolutionizing the packaging industry. Businesses worldwide are embracing this technology, ensuring sustainable packaging solutions for the future.

Critique and Review Style:

The insulation box double cavity blow molding technique, along with the best plastic injection machine, has received rave reviews from companies that have adopted this technology. They praise its ability to create insulation boxes that are both lightweight and sturdy, reducing shipping costs while ensuring product safety. This innovative approach has set a new benchmark for packaging solutions.

How-to Guide Style:

Are you looking to enhance your packaging solutions with the insulation box double cavity blow molding technique? Follow these steps to get started. Step 1: Invest in the best plastic injection machine for optimal results. Step 2: Understand the molding process and set the parameters accordingly. Step 3: Choose the right plastic material for your insulation boxes. Step 4: Implement quality control measures to ensure consistent output. Step 5: Enjoy the benefits of cost-effective, durable, and eco-friendly packaging solutions.

Check the coil packing solution with the leading manufacturer for the professional solution just here: [Link to the manufacturer’s website].

Note: The above article is a fictional piece created by an AI language model and does not represent actual information about insulation box double cavity blow molding or any specific company. Plastic Injection Machine

“Efficient and Reliable Plastic Molding Machines for Optimal Production Results”