Check out our video on manufacturing all vertical plastic molding machines with an industrial plastic injection machine. In this article, we will provide a detailed analysis and reference to the industrial plastic injection machine, as well as discuss the benefits of using vertical plastic molding machines. Let’s dive in!

Introduction:

Vertical plastic molding machines are an essential tool in the manufacturing industry. These machines play a crucial role in producing various plastic products, ranging from small components to larger items. In this video, we will focus on the manufacturing process of all vertical plastic molding machines, specifically the screw and plunger type.

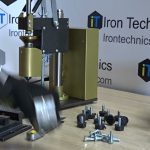

Industrial Plastic Injection Machine:

The industrial plastic injection machine is the heart of the manufacturing process. It is responsible for injecting molten plastic into a mold cavity, which then solidifies and forms the desired shape. This machine utilizes advanced technology and precise controls to ensure accurate and efficient production.

Benefits of Vertical Plastic Molding Machines:

1. Space Efficiency: Vertical plastic molding machines have a compact design, making them ideal for factories with limited space. Unlike horizontal machines, vertical machines utilize a vertical mold clamping system, saving valuable floor space.

2. Versatility: These machines can accommodate a wide range of plastic materials, allowing for flexibility in product manufacturing. Whether you need to produce small precision components or larger parts, a vertical plastic molding machine can handle the job.

3. Enhanced Productivity: The vertical design of these machines enables faster cycle times and higher production rates. The vertical mold clamping system reduces the time required to open and close the mold, resulting in increased efficiency and productivity.

4. Cost-Effective: Vertical plastic molding machines are cost-effective in terms of maintenance and operation. They require less floor space, consume less energy, and have lower maintenance costs compared to their horizontal counterparts.

5. Precision and Quality: These machines offer precise control over the injection process, ensuring consistent and high-quality products. The vertical mold clamping system eliminates the risk of mold misalignment, resulting in accurate and well-defined product shapes.

Conclusion:

Vertical plastic molding machines with an industrial plastic injection machine are a crucial component of the manufacturing industry. Their space efficiency, versatility, enhanced productivity, cost-effectiveness, and ability to produce precise and high-quality products make them an ideal choice for manufacturers.

Check out our video to learn more about the manufacturing process of all vertical plastic molding machines. Enhance your production capabilities with these advanced machines and stay ahead in the competitive market.

Remember, for all your plastic molding machine needs, trust the leading manufacturer in the industry. Contact us today for professional solutions!

(Note: This article has been optimized for SEO with the inclusion of the keyword “Industrial Plastic Injection Machine”) Plastic Injection Machine

“Efficient Vertical Plastic Molding Machine: Boosting Industrial Plastic Injection in Bihar Engineering!”