“Check out the leading manufacturer for professional packaging solutions here:”

Industrial Filling Packing Machine: Revolutionizing Packaging Processes

Introduction:

In today’s fast-paced world, efficient and reliable packaging machinery plays a crucial role in ensuring the smooth flow of goods from production to consumers. Industrial Filling Packing Machines, including filling, capping, sealing, labeling, bagging, and cartoning machines, have become indispensable in various industries. In this article, we will explore the benefits of these machines, their applications, and how they have revolutionized the packaging industry.

I. Explanatory Style – Understanding Industrial Filling Packing Machines

To truly appreciate the significance of Industrial Filling Packing Machines, we must first understand their core functionalities and components. These machines are designed to automate the packaging process, reducing human error and increasing efficiency.

1. Filling Machines:

Filling machines are used to accurately fill products into containers, such as bottles or pouches. They utilize advanced technology to ensure precise measurements and minimize wastage. From liquid to granular products, filling machines cater to a wide range of industries, including food and beverage, pharmaceuticals, and cosmetics.

2. Capping Machines:

Capping machines are responsible for securing caps or lids onto containers. They ensure a tight seal, preventing leakage and maintaining product integrity. With various cap types and sizes, capping machines are adaptable to different packaging requirements.

3. Sealing Machines:

Sealing machines provide airtight and tamper-evident seals for containers. Whether it’s induction sealing for bottles or heat sealing for pouches, these machines guarantee product freshness and safety. Sealing machines are especially critical in the food and pharmaceutical industries, where product quality and consumer trust are paramount.

4. Labeling Machines:

Labeling machines accurately apply labels to products or packaging materials. They can handle various label types, including self-adhesive, shrink sleeve, and wrap-around labels. These machines ensure consistent placement and eliminate the need for manual labeling, saving time and enhancing branding efforts.

5. Bagging Machines:

Bagging machines automate the process of packaging products into bags, pouches, or sachets. They can handle a wide range of products, including powders, granules, and liquids. Bagging machines offer speed and precision, making them essential in industries such as food, pet care, and chemical manufacturing.

6. Cartoning Machines:

Cartoning machines assemble and seal cartons or boxes, ready for product packaging. They streamline the process of packaging multiple items into a single unit, eliminating the need for manual carton assembly. Cartoning machines are widely used in industries such as pharmaceuticals, household goods, and electronics.

II. Case Study Style – Real-Life Applications of Industrial Filling Packing Machines

To understand the practical impact of Industrial Filling Packing Machines, let’s explore a case study in the fruit packaging industry.

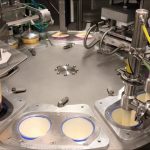

Case Study: Automatic Fruit Industrial Pillow Type Bag Filling Sealing Packing Machine

In the fruit packaging industry, the demand for quick and efficient packaging solutions is ever-increasing. The Automatic Fruit Industrial Pillow Type Bag Filling Sealing Packing Machine has emerged as a game-changer in this sector.

This machine automates the process of filling, sealing, and packing fresh fruits into pillow-type bags. It ensures consistent bagging and sealing, minimizing product damage and improving shelf life. With its high-speed capabilities, this machine significantly increases productivity and reduces labor costs.

The Automatic Fruit Industrial Pillow Type Bag Filling Sealing Packing Machine is compatible with various fruit sizes and types, making it versatile for different packaging needs. Its user-friendly interface and intuitive controls allow for easy operation and quick changeovers.

III. In-depth Analysis Style – The Future of Industrial Filling Packing Machines

As technology continues to advance, Industrial Filling Packing Machines are poised to evolve further, offering enhanced capabilities and efficiency. Here are some predictions for the future of these machines:

1. Integration of Artificial Intelligence (AI):

AI-powered systems can analyze data and make real-time adjustments to optimize packaging processes. By incorporating AI, Industrial Filling Packing Machines can adapt to different products, packaging materials, and environmental conditions, ensuring maximum efficiency and quality.

2. Increased Sustainability:

As environmental concerns grow, manufacturers are focusing on sustainable packaging solutions. Industrial Filling Packing Machines will play a crucial role in reducing material waste, optimizing energy consumption, and utilizing eco-friendly packaging materials.

3. Advanced Sensor Technology:

By leveraging sensor technology, Industrial Filling Packing Machines can detect and rectify issues promptly. Sensors can monitor factors like product flow, package integrity, and machine performance, enabling proactive maintenance and minimizing downtime.

Conclusion:

Industrial Filling Packing Machines have revolutionized the packaging industry, offering speed, accuracy, and efficiency. From filling to cartoning, these machines automate critical packaging processes, reducing labor costs and ensuring product quality. As technology advances, these machines will continue to play a pivotal role in meeting the demands of the ever-evolving packaging industry.

Check out the leading manufacturer for professional packaging solutions here. Filling Packing Machine

“Efficient and Versatile Pillow-Type Bag Filling and Sealing Machine for Fruit Packaging”