Title: High-Speed Automatic Packing Line for Plastic and Dental Products | Flow Pack Packing Machine

Description:

Welcome to our High-Speed Automatic Packing Line video, showcasing our cutting-edge technology in the packaging industry. This video focuses on our high speed automatic packing line and flow pack packing machine, specifically designed for plastic and dental products.

Introduction:

In this video, we provide an in-depth look at our advanced packing line, highlighting its efficiency, speed, and reliability. Whether you’re in the plastic or dental industry, our state-of-the-art packing solution is tailored to meet your specific packaging needs.

Video Content:

1. Overview of the High-Speed Automatic Packing Line:

– Discover how our packing line revolutionizes the packaging process, ensuring faster production and improved output.

– Learn about the various components and features of our automated system that contribute to its high-speed capabilities.

– Understand how this packing line can handle a wide range of plastic and dental products with precision and accuracy.

2. Key Benefits and Features:

– Explore the advantages of our high-speed packing line, such as reduced labor costs, increased productivity, and minimized errors.

– Witness the seamless integration of our flow pack packing machine, which optimizes the packaging process for both plastic and dental products.

– Learn about the customizable options available, allowing you to adapt the packing line to your specific product requirements.

3. Operation Steps:

– Dive into a step-by-step demonstration of how our packing line operates, showcasing its user-friendly interface and intuitive controls.

– Gain insights into the efficient loading and unloading processes, ensuring a smooth and uninterrupted workflow.

– Understand the quality control measures in place to guarantee the integrity of the packaged products.

Call to Action:

If you found this video informative and valuable, don’t forget to give it a thumbs up and subscribe to our channel for more industry-related content. Share this video with your colleagues and network to spread the word about our high-speed packing line.

Additional Tags and Keywords:

High-Speed Automatic Packing Line, High Speed Packing Machine, Flow Pack Packing Line, Plastic Products, Dental Products, Packaging Industry, Automated System, Efficiency, Precision, User-friendly Interface, Productivity, Quality Control.

Hashtags:

#HighSpeedPackingLine #AutomaticPackingMachine #FlowPackPacking #PlasticProducts #DentalProducts #PackagingIndustry

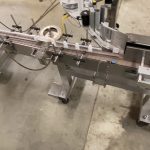

A tilter for a high-speed automatic packing line is a crucial component that helps align and position the products correctly before they are packed. Here’s a basic outline for a tilter:

1. Design and Structure:

– Start by designing a sturdy and durable frame for the tilter.

– Use high-quality materials, such as stainless steel or aluminum, to ensure reliability and longevity.

– Incorporate safety features, including emergency stop buttons and protective guards.

2. Conveyor System:

– Integrate a conveyor system that can handle high-speed operations.

– The conveyor should be adjustable in terms of speed and height to accommodate different product sizes and packing requirements.

– Consider using a modular belt conveyor for better control and flexibility.

3. Tilting Mechanism:

– Implement a motorized tilting mechanism to adjust the angle of the products.

– Use servo motors for precise control and quick response times.

– The tilting mechanism should be able to handle a wide range of product weights and dimensions.

4. Sensors and Control System:

– Install sensors to detect the presence and position of products on the conveyor.

– Use proximity sensors or vision systems for accurate detection.

– Implement a PLC (Programmable Logic Controller) or microcontroller-based control system to manage the tilter’s operations.

– Develop a user-friendly interface to set tilting angles, speed, and other parameters.

5. Integration with Packing Line:

– Ensure seamless integration with the overall packing line.

– Coordinate the tilter’s operations with other equipment, such as filling stations, sealing machines, or labeling systems.

– Use communication protocols, like Modbus or Ethernet/IP, to enable data exchange between different components of the packing line.

6. Testing and Optimization:

– Conduct thorough testing to ensure the tilter meets the required speed and accuracy specifications.

– Optimize the control algorithms for smooth and precise tilting operations.

– Perform stress testing to validate the tilter’s durability and endurance under high-speed and continuous operation.

Remember, this is just a general outline, and the actual design and implementation of a tilter for a high-speed automatic packing line may vary based on specific requirements and constraints. It’s always recommended to consult with experts and engineers to tailor the tilter to your specific needs. coil packing line

#high #speed #automatic #packing #line