Title: “Efficient Pallet Wrapping with the Muller Yellow Jacket Orbital Stretch Wrap Machine”

Description:

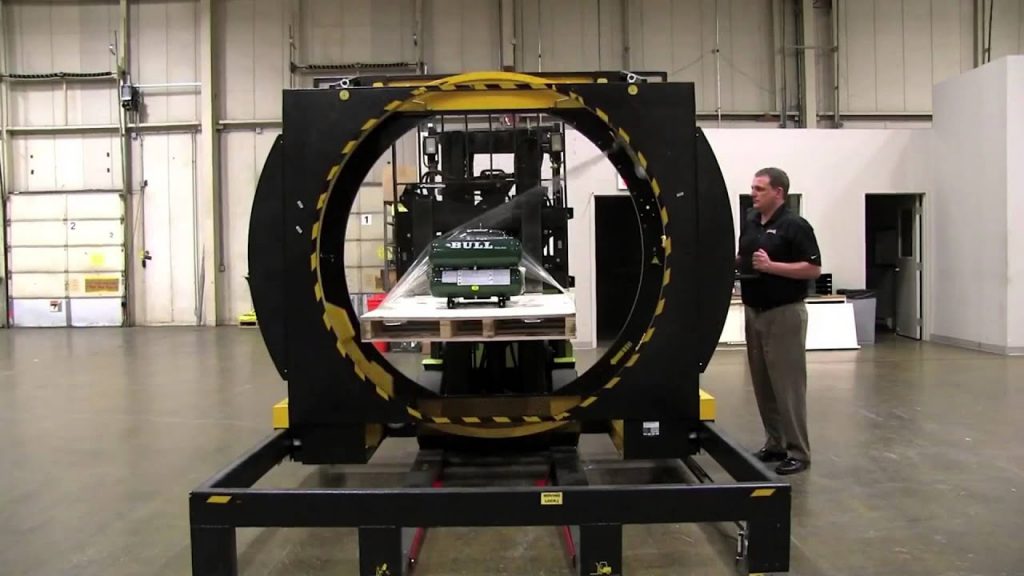

Welcome to our video showcasing the remarkable capabilities of the Muller Yellow Jacket Orbital Stretch Wrap Machine. If you are looking for a reliable solution to secure oversized, oddly shaped, palletized loads, this machine is the perfect fit for your needs. With its advanced features and innovative design, the Yellow Jacket ensures optimal stability and protection for your valuable goods during transit.

Introduction:

In this video, we present the Muller Yellow Jacket Orbital Stretch Wrap Machine, a game-changer in the world of pallet wrapping. We will demonstrate its exceptional functionality, highlighting its ability to secure and stabilize even the most challenging loads.

Video Content:

1. Unparalleled Load Security: The Yellow Jacket offers outstanding load containment, allowing you to confidently transport your palletized loads without the risk of shifting or damage. Its orbital wrapping mechanism ensures maximum stability, minimizing the chances of product loss.

2. Versatile for Any Load: Regardless of the size or shape of your palletized loads, the Yellow Jacket adapts effortlessly. Featuring customizable wrapping options, you can easily adjust the machine to accommodate different load dimensions, guaranteeing a snug and secure fit every time.

3. Streamlined Operation: Operating the Yellow Jacket is a breeze, thanks to its user-friendly interface and intuitive controls. We will guide you through the step-by-step process, showcasing how to efficiently wrap your pallets and optimize your workflow.

4. Time and Cost Savings: By automating the wrapping process, the Yellow Jacket significantly reduces labor requirements and improves overall productivity. Its efficient operation saves valuable time, allowing your team to focus on other critical tasks. Additionally, the machine’s stretch film usage optimization helps minimize material waste, resulting in cost savings for your business.

5. Enhanced Load Protection: The Yellow Jacket’s advanced stretch wrapping technology provides a protective barrier against moisture, dust, and other external elements. This ensures that your products arrive at their destination in pristine condition, maintaining your brand’s reputation for quality.

Call to Action:

If you are ready to revolutionize your pallet wrapping process and enhance the safety and security of your shipments, don’t hesitate to invest in the Muller Yellow Jacket Orbital Stretch Wrap Machine. Like, subscribe, and share this video to spread the word about this exceptional solution. Visit our channel for more informative content on optimizing your packaging operations.

Additional Tags and Keywords: pallet wrapping machine, stretch wrap machine, Yellow Jacket wrap machine, pallet load security, efficient pallet wrapping, orbital stretch wrapping, load containment, optimized workflow, cost-effective packaging, pallet wrapping automation.

Hashtags: #PalletWrappingMachine #YellowJacketWrapMachine #LoadSecurity #StretchWrapAutomation #EfficientPackaging

Sure! Here’s a sample tilter for the Muller Yellow Jacket Orbital Stretch Wrap Machine:

Title: “Maximize Efficiency and Safety with the Muller Yellow Jacket Orbital Stretch Wrap Machine Tilter”

Introduction:

– Introduce the Muller Yellow Jacket Orbital Stretch Wrap Machine as a cutting-edge solution for efficient and safe stretch wrapping.

– Highlight the importance of a tilter in enhancing the machine’s functionality and productivity.

– Present the main goal of the tilter: to optimize load stability and reduce the risk of damage during the wrapping process.

Section 1: Benefits of the Muller Yellow Jacket Orbital Stretch Wrap Machine Tilter

1.1 Improved Load Stability:

– Explain how the tilter ensures that the load is properly aligned and secured, minimizing the risk of shifting or toppling during transportation.

– Emphasize the tilter’s role in preventing product damage and reducing the need for rewrapping.

1.2 Enhanced Ergonomics:

– Discuss how the tilter simplifies the loading and unloading process by providing a convenient tilt angle for accessing the load.

– Highlight the ergonomic benefits of reducing worker strain and fatigue, resulting in increased productivity and employee satisfaction.

Section 2: Key Features and Functionality

2.1 Adjustable Tilt Angle:

– Describe the tilter’s ability to tilt the load to various angles, allowing for easy access to all sides for wrapping and unwrapping.

– Explain how this feature enables efficient handling of irregularly shaped or oversized loads.

2.2 User-Friendly Controls:

– Discuss the intuitive control panel that allows operators to adjust the tilt angle and other settings with ease.

– Emphasize the importance of user-friendly controls in reducing training time and minimizing errors during operation.

Section 3: Safety Measures

3.1 Load Weight Capacity:

– Highlight the tilter’s ability to handle heavy loads, ensuring safe and secure wrapping even for large-scale applications.

– Mention the load weight capacity and emphasize the importance of adhering to these limits to prevent accidents or equipment damage.

3.2 Built-in Safety Features:

– Discuss the safety mechanisms integrated into the tilter, such as emergency stop buttons, safety sensors, and automatic load detection.

– Explain how these features contribute to a safer working environment and protect both the operator and the equipment.

Conclusion:

– Recap the benefits of using the Muller Yellow Jacket Orbital Stretch Wrap Machine Tilter, including improved load stability, enhanced ergonomics, and increased safety.

– Encourage readers to consider implementing a tilter as a valuable addition to their Muller Yellow Jacket Orbital Stretch Wrap Machine, maximizing efficiency and protecting their products during transportation. pallet wrapping machine

#Muller #Yellow #Jacket #Orbital #Stretch #Wrap #Machine