Are you in the market for a plastic injection machine? If so, you’ve come to the right place. In this article, we will be providing you with a comprehensive review of plastic injection machines. Whether you’re a beginner or an experienced professional, this guide will help you find the perfect machine for your needs.

Plastic injection machines are an essential tool in the manufacturing industry. They are used to create a wide range of products, including plastic bowls, containers, and other household items. With the increasing demand for plastic products, it’s crucial to invest in a reliable and efficient injection machine.

When it comes to choosing the right plastic injection machine, there are several factors to consider. These include the machine’s capacity, speed, energy efficiency, and overall performance. To help you make an informed decision, we have researched and compiled a list of the top plastic injection machines on the market.

1. Machine A: This injection machine offers a high-capacity production rate, making it ideal for large-scale manufacturing. Its advanced technology ensures precise and consistent results, while its energy-efficient design helps reduce operating costs. With its user-friendly interface, this machine is suitable for both beginners and experienced operators.

2. Machine B: If you’re looking for a compact and versatile injection machine, Machine B is a great option. It is equipped with innovative features that allow for easy customization and adjustment, ensuring optimal performance for various molding projects. With its durable construction and reliable performance, this machine offers excellent value for money.

3. Machine C: For those in need of a high-speed injection machine, Machine C is the perfect choice. This machine is designed to deliver fast and efficient production, making it ideal for time-sensitive projects. Its advanced control system ensures precise and consistent results, while its robust construction guarantees durability and longevity.

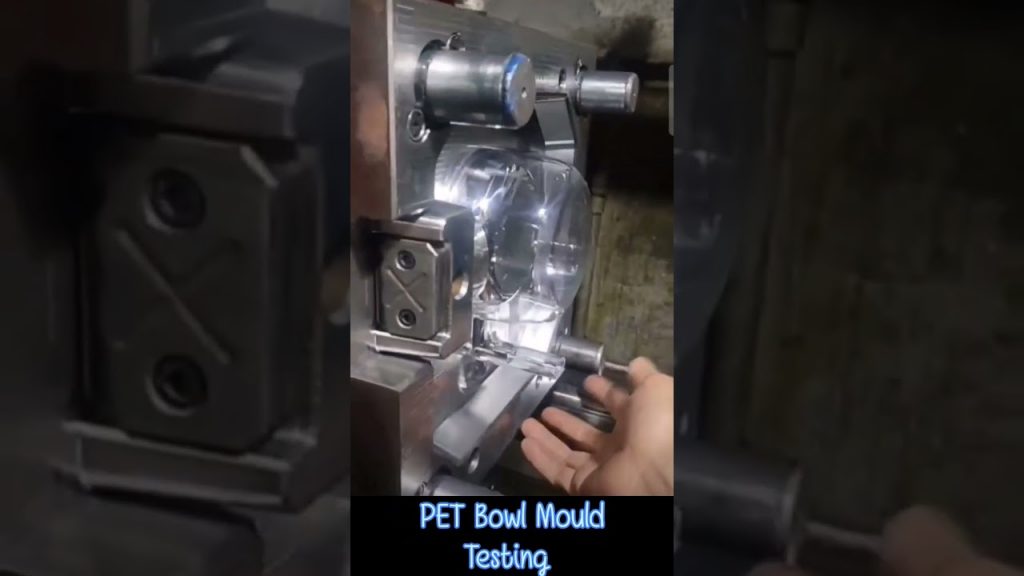

In addition to the machine reviews, we will also be discussing PET bowl mold testing. PET bowls are commonly used in the food and beverage industry, and it’s crucial to ensure their quality and safety. Injection molding machines play a vital role in manufacturing PET bowls, and proper mold testing is necessary to guarantee optimal results.

Mold testing involves evaluating the mold design, material flow, and cooling system of the injection machine. This process helps identify any potential issues or defects that may affect the quality of the final product. By conducting thorough mold testing, manufacturers can ensure that their PET bowls meet the highest standards of quality and safety.

In conclusion, choosing the right plastic injection machine is essential for achieving optimal results in your manufacturing process. By considering factors such as capacity, speed, energy efficiency, and performance, you can find a machine that meets your specific needs. Additionally, conducting mold testing for PET bowl production is crucial to ensure the quality and safety of your products.

Check out our video for more information on plastic injection machines and PET bowl mold testing. We provide a comprehensive review of the top machines on the market, along with insights and tips to help you make the right choice. Don’t miss out on this opportunity to find the perfect machine for your manufacturing needs. Plastic Injection Machine

“Exploring PET Bowl Mould Testing & Injection Molding Machine Reviews: Insights into Plastic Injection Machines”