In today’s fast-paced manufacturing industry, efficiency and productivity are key factors for success. One crucial aspect of this industry is the handling of heavy materials, such as metal sheets. With the advancements in technology, handling machine manufacturers have come up with innovative solutions to address the challenges faced in this area. In this article, we will explore the benefits of a depalletizer with a modular design that requires low space, can be easily moved, and is sturdy enough to hold heavy weights.

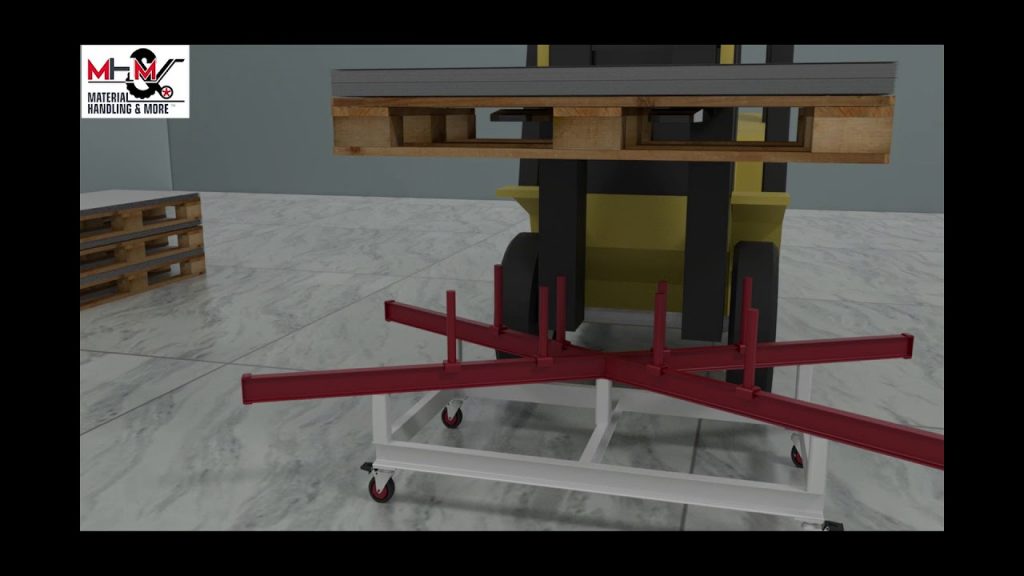

When it comes to material handling equipment, the depalletizer plays a vital role. It is designed to efficiently unload pallets and handle heavy loads, making it an essential tool in any manufacturing facility. One of the standout features of a depalletizer is its modular design, which allows for easy customization and integration into existing production lines. This flexibility ensures that the depalletizer can adapt to the specific needs of each facility, maximizing efficiency and productivity.

The compact nature of the depalletizer is another advantage for manufacturers with limited space. Traditional handling machines often take up a significant amount of floor space, making it challenging to optimize the layout of the production area. However, with a depalletizer’s modular design, it requires minimal space, allowing for better space utilization and efficient workflow.

Furthermore, the ability to easily move the depalletizer to any location adds to its versatility. In a dynamic manufacturing environment, where production lines are constantly evolving, the ability to relocate equipment quickly becomes a valuable asset. Whether it’s a layout change or the need to accommodate new production demands, the depalletizer’s mobility ensures seamless integration without disrupting the overall workflow.

One of the critical factors to consider when investing in a depalletizer is its ability to handle heavy weights, especially in the case of metal sheet handling. Metal sheets can be bulky and challenging to maneuver manually. The depalletizer’s sturdy construction allows it to effortlessly handle heavy loads, ensuring a safe and efficient material handling process. This not only reduces the risk of accidents but also minimizes downtime and increases productivity.

For manufacturers looking to optimize their material handling processes, partnering with a reliable handling machine manufacturer is crucial. MH&More, a leading depalletizer manufacturer, offers a wide range of solutions tailored to meet the specific needs of various industries. Their expertise in material handling equipment ensures that customers receive top-quality products that enhance operational efficiency.

In conclusion, the depalletizer with a modular design, low space requirement, easy mobility, and sturdy construction is revolutionizing the way manufacturers handle heavy materials like metal sheets. Its ability to adapt to different production environments and efficiently unload pallets makes it an invaluable asset for any manufacturing facility. By partnering with reputable handling machine manufacturers like MH&More, manufacturers can unlock the full potential of their material handling processes and achieve optimal efficiency.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert appropriate link]. Handling Machine

“Efficient Solutions for Streamlining Packaging Operations: Discover Top Depalletizer and Metal Sheet Handling Technologies”