Title: Semi-Automatic Labeling Machine: Efficient and Precise Labeling for Round Bottles

Description:

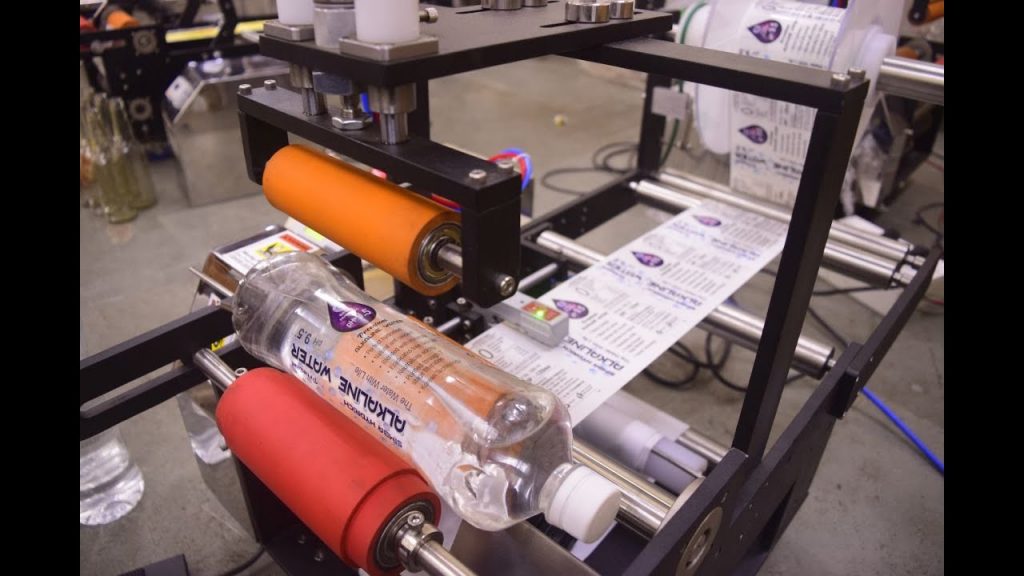

Welcome to Tru Mark’s presentation on the Semi-Automatic Labeling Machine, a cutting-edge solution designed to streamline labeling processes for round bottles. With its advanced features and user-friendly interface, this labeling machine ensures efficient and accurate labeling, saving both time and resources.

Introduction:

In this video, we delve into the world of labeling machinery and showcase the Semi-Automatic Labeling Machine. Whether you are in the pharmaceutical, food and beverage, or cosmetic industry, this machine is an invaluable asset for your labeling needs.

Video Content:

Our video provides an in-depth look into the operation and functionality of the Semi-Automatic Labeling Machine. We highlight its key features, including its semi-automatic nature, which allows for quick and precise application of labels on round bottles. From small businesses to large-scale production lines, this machine caters to a wide range of labeling requirements.

Key Highlights:

– Efficient Semi-Automatic Labeling: Discover how this machine automates the labeling process, reducing manual effort and increasing productivity.

– Precise Round Bottle Labeling: Explore the machine’s ability to accurately apply labels on round bottles of varying sizes, ensuring a professional finish.

– User-Friendly Interface: Learn about the intuitive interface that simplifies operation, making it accessible for both experienced operators and newcomers.

– Versatility for Different Industries: Find out how this machine adapts to various industries, accommodating different bottle shapes, sizes, and label types.

Call to Action:

If you found this video informative and helpful, please consider liking, subscribing, and sharing it with others in your industry. Stay updated with the latest advancements in labeling technology by subscribing to our channel.

Additional Tags and Keywords:

Semi-Automatic Labeling Machine, Semi Auto Round Bottle Labeling Machine, labeling machinery, efficient labeling, precise labeling, round bottle labeling, labeling automation, labeling technology, labeling solutions, Tru Mark.

Hashtags:

#labelingmachine #roundbottlelabeling #automation #labelingsolutions #TruMark

Here’s a sample tilter for a Semi Auto Round Bottle Labeling Machine:

Title: Semi Auto Round Bottle Labeling Machine Tilter: Ensuring Accurate and Efficient Label Placement

Introduction:

The Semi Auto Round Bottle Labeling Machine is a valuable tool in the packaging industry, simplifying the process of applying labels to round bottles efficiently. To further enhance its capabilities, the addition of a tilter mechanism can offer precise label placement, ensuring accurate alignment and reducing manual adjustments. This article discusses the features, benefits, and working principle of the tilter for the Semi Auto Round Bottle Labeling Machine.

Features of the Tilter:

1. Adjustable Angle: The tilter mechanism allows for the adjustment of the bottle’s angle, accommodating various bottle sizes and shapes.

2. Secure Holding: It securely holds the bottle in place during the labeling process, preventing slippage or misalignment.

3. Quick Release System: The tilter offers a quick release system, allowing for easy bottle loading and unloading, minimizing downtime.

4. Compatibility: The tilter is designed to seamlessly integrate with the Semi Auto Round Bottle Labeling Machine, ensuring smooth operation.

Benefits of the Tilter:

1. Accurate Label Placement: The tilter ensures precise alignment of labels on round bottles, reducing errors and enhancing product presentation.

2. Time-Efficient: With the tilter, the labeling process is streamlined, minimizing the need for manual adjustments and maximizing productivity.

3. Versatility: The adjustable angle feature of the tilter allows for labeling bottles of different shapes and sizes, making it highly versatile in various packaging applications.

4. User-Friendly: The tilter’s quick release system simplifies the loading and unloading of bottles, making it easy for operators to handle.

Working Principle:

The tilter for the Semi Auto Round Bottle Labeling Machine operates by securing the bottle in place using adjustable clamps or grips. It allows the bottle to be positioned at the desired angle for labeling. Once the bottle is secured, the labeling machine applies the label accurately onto the bottle’s surface. The tilter ensures the bottle remains stable throughout the labeling process, preventing any misalignment or slippage. After labeling, the tilter’s quick release system allows for easy removal of the labeled bottle and reloading of the next one.

Conclusion:

The addition of a tilter to the Semi Auto Round Bottle Labeling Machine brings significant advantages in terms of accurate label placement, time-efficiency, versatility, and user-friendliness. By investing in this tilter mechanism, packaging companies can improve their labeling process, enhance product presentation, and optimize overall productivity.Labeling Machine

#Semi #Auto #Bottle #Labeling #Machine