Title: High-Quality Labeling Machine Manufacturers | Weaving Label Machine for Efficient Labeling

Description:

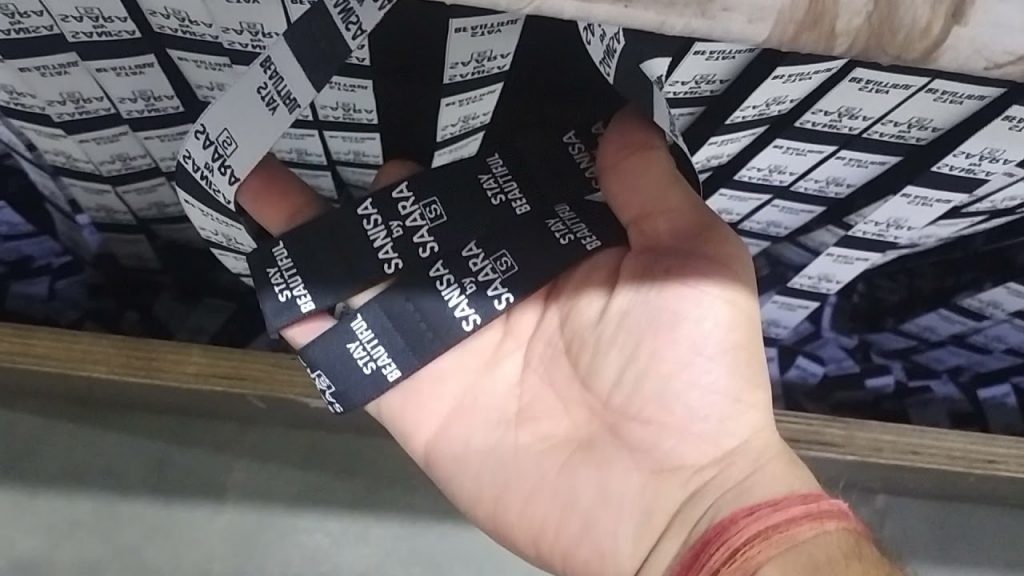

Welcome to our comprehensive video on Labeling Machine Manufacturers and the advanced weaving label machine used for efficient label production. In this video, we provide a detailed overview of the key features, benefits, and operation steps of these cutting-edge machines.

Introduction:

Discover the world of Labeling Machine Manufacturers and explore the innovative weaving label machine that revolutionizes label production. This video offers valuable insights into the latest advancements in the industry, providing you with a comprehensive understanding of the benefits and capabilities of these machines.

Video Content:

In this video, we delve into the fascinating world of labeling machines and showcase the exceptional features of the weaving label machine. With its state-of-the-art technology and precision engineering, this machine guarantees high-quality and efficient label production.

Key Highlights:

– Unparalleled Accuracy: Experience precise label placement with the advanced alignment mechanisms incorporated in these machines.

– Speed and Efficiency: Witness the impressive speed and efficiency of the weaving label machine, ensuring increased productivity and reduced production time.

– Customization Options: Explore the various customization options available, allowing you to create unique labels that perfectly align with your brand’s identity.

– Easy Operation: Learn about the user-friendly interface and intuitive controls, simplifying the operation process and minimizing training requirements.

– Durability and Reliability: Discover the robust construction and long-lasting performance of these machines, ensuring uninterrupted label production even in demanding environments.

Operation Steps:

1. Prepare the label design and material for weaving.

2. Set up the weaving label machine, ensuring proper alignment and tension.

3. Input the label design specifications into the machine’s control panel.

4. Initiate the weaving process and observe the machine’s precise label production.

5. Remove the finished labels and proceed to the next batch for continuous production.

Call to Action:

If you found this video informative and insightful, we encourage you to like, subscribe, and share it with others who might benefit from it. Stay updated with our latest videos on labeling machine manufacturers and industry advancements by subscribing to our channel.

Additional Tags and Keywords:

Labeling machine, weaving label machine, label production, high-quality labels, efficient labeling, precision engineering, customization options, advanced technology, user-friendly interface, durability, reliability, label design, label material

Hashtags:

#LabelingMachineManufacturers #WeavingLabelMachine #EfficientLabeling #LabelProduction #PrecisionEngineering

Here is a sample code for a tilter program for a woven label machine:

“`

#include

// Define the pin for the servo motor

const int servoPin = 9;

// Define the angles for tilt positions

const int tiltAngle1 = 0; // First tilt position

const int tiltAngle2 = 90; // Second tilt position

// Define the delay time for each tilt position (in milliseconds)

const int tiltDelay = 1000;

Servo servo; // Create a servo object

void setup() {

// Attach the servo to the pin

servo.attach(servoPin);

}

void loop() {

// Tilt to the first position

tiltToPosition(tiltAngle1);

// Delay for a certain amount of time

delay(tiltDelay);

// Tilt to the second position

tiltToPosition(tiltAngle2);

// Delay for a certain amount of time

delay(tiltDelay);

}

void tiltToPosition(int angle) {

// Move the servo to the specified angle

servo.write(angle);

delay(15); // Allow time for servo to reach the angle

}

“`

This code uses the Servo library to control the servo motor connected to pin 9. It defines two tilt positions (0 and 90 degrees) and a delay time between each tilt. The `tiltToPosition` function is used to tilt the machine to the specified angle. In the `loop` function, it continuously tilts the machine back and forth between the two positions with the specified delay time.Labeling Machine

#woven #label #machine #weaving #label