Title: SP-1310PB Automatic Labeling Machine – Efficient and Reliable Label Attaching Solution

Description:

Introduction:

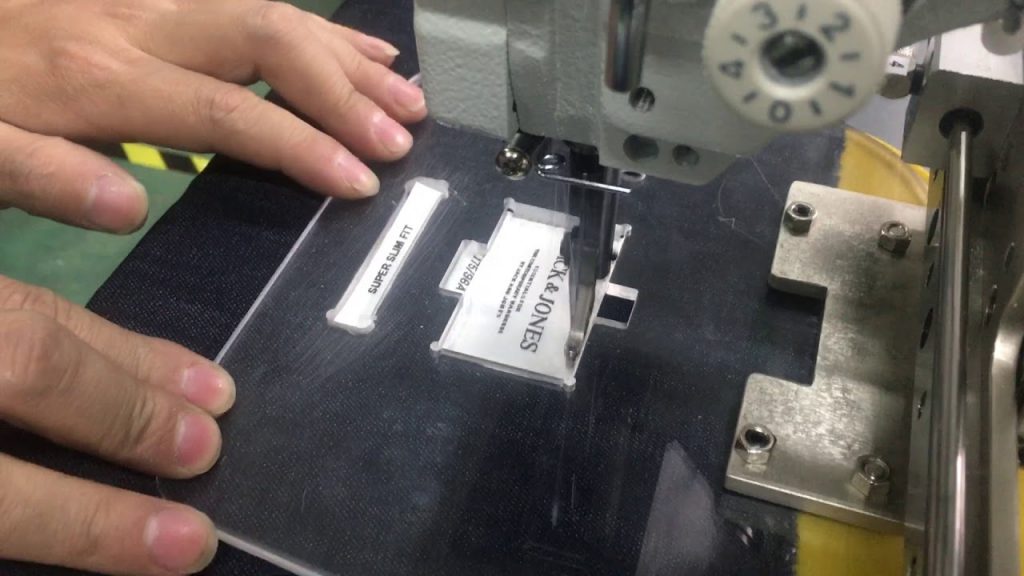

Welcome to our video showcasing the SP-1310PB Automatic Labeling Machine, a cutting-edge solution for efficient and reliable label attaching. In this video, we will explore the features, benefits, and operation steps of this advanced labeling machine.

Video Content:

The SP-1310PB Automatic Labeling Machine is designed to streamline your labeling process, offering maximum productivity and accuracy. With its state-of-the-art technology and user-friendly interface, this machine is perfect for various industries that require precise label application.

Key Features:

– High Speed and Accuracy: The SP-1310PB can label an impressive number of products per minute, ensuring efficient production without compromising precision.

– Versatile Labeling Options: This machine supports a wide range of label sizes and shapes, providing flexibility to accommodate diverse labeling requirements.

– Easy Integration: With its user-friendly interface and adjustable settings, this labeling machine seamlessly integrates into your existing production line, minimizing downtime and maximizing efficiency.

– Reliable Performance: Built with top-quality materials and advanced components, the SP-1310PB ensures long-lasting durability and consistent performance.

Operation Steps:

1. Preparation: Set up the machine by adjusting the label size, speed, and other settings according to your specific labeling needs.

2. Loading: Load the labels into the machine’s feeding system, ensuring a smooth and uninterrupted labeling process.

3. Product Placement: Position the products to be labeled in the designated area, ensuring proper alignment and spacing.

4. Label Application: Start the machine and witness the SP-1310PB’s precise and efficient label attachment as it seamlessly applies labels to the products.

5. Quality Check: After labeling, inspect the products to ensure accurate placement and adherence of the labels.

6. Repeat: Continuously repeat the above steps for efficient and uninterrupted labeling.

Call to Action:

If you are looking for an automatic labeling solution that can significantly enhance your production efficiency, the SP-1310PB Automatic Labeling Machine is the perfect choice. Don’t miss out on this opportunity to streamline your labeling process and increase your productivity. Like, subscribe, and share this video to stay updated on the latest labeling technology.

Additional Tags and Keywords: automatic labeling machine, label attaching machine, label applicator, labeling equipment, labeling solution, industrial labeling, efficient labeling, labeling technology, high-speed labeling.

Hashtags: #AutomaticLabelingMachine #LabelAttachingMachine #EfficientLabelingSolution #IndustrialLabeling #ProductivityEnhancement

Here is a sample code for a tilter for the SP-1310PB Label Attaching Machine:

“`python

import RPi.GPIO as GPIO

import time

# Define the GPIO pins for the tilter motor

tilter_pin1 = 17

tilter_pin2 = 18

# Set the GPIO mode and setup the pins

GPIO.setmode(GPIO.BCM)

GPIO.setup(tilter_pin1, GPIO.OUT)

GPIO.setup(tilter_pin2, GPIO.OUT)

# Function to tilt the machine

def tilt_machine(duration):

GPIO.output(tilter_pin1, GPIO.HIGH) # Set pin1 to HIGH

GPIO.output(tilter_pin2, GPIO.LOW) # Set pin2 to LOW

time.sleep(duration) # Wait for the specified duration

GPIO.output(tilter_pin1, GPIO.LOW) # Set pin1 to LOW

GPIO.output(tilter_pin2, GPIO.LOW) # Set pin2 to LOW

# Example usage

tilt_duration = 2 # Tilt for 2 seconds

tilt_machine(tilt_duration)

# Cleanup the GPIO pins

GPIO.cleanup()

“`

Make sure to connect the tilter motor to the appropriate GPIO pins (tilter_pin1 and tilter_pin2) on your Raspberry Pi. Adjust the GPIO pin numbers and tilt duration according to your setup.Labeling Machine

#SP1310PB #Label #Attaching #Machine