If you’re in the market for an Automatic Plastic Injection Machine, you’ve come to the right place. In this video, we will explore the features and benefits of this innovative machine and how it can revolutionize your plastic molding business. Whether you’re a small-scale manufacturer or a large factory, this machine is designed to meet your production needs efficiently and effectively.

Introduction to Automatic Plastic Injection Machine

Automatic Plastic Injection Machines have become increasingly popular in the manufacturing industry due to their ability to streamline the injection molding process. These machines are designed to produce plastic products by injecting molten plastic into a mold cavity. The process is automated, ensuring precision and accuracy in every production cycle.

Features and Benefits

1. High Efficiency: With the use of advanced technology, Automatic Plastic Injection Machines can produce plastic products at a much faster rate compared to traditional methods. This high efficiency translates to increased productivity and reduced production costs.

2. Precision and Accuracy: The automated process of these machines ensures precise and accurate injection of plastic into the mold cavity. This eliminates human error and guarantees consistent quality in every product.

3. Cost Savings: By automating the injection molding process, businesses can significantly reduce labor costs. Additionally, the high efficiency of these machines reduces energy consumption, resulting in further cost savings.

4. Versatility: Automatic Plastic Injection Machines are capable of producing a wide range of plastic products, from small components to larger items. This versatility makes them suitable for various industries, including packaging, automotive, and consumer goods.

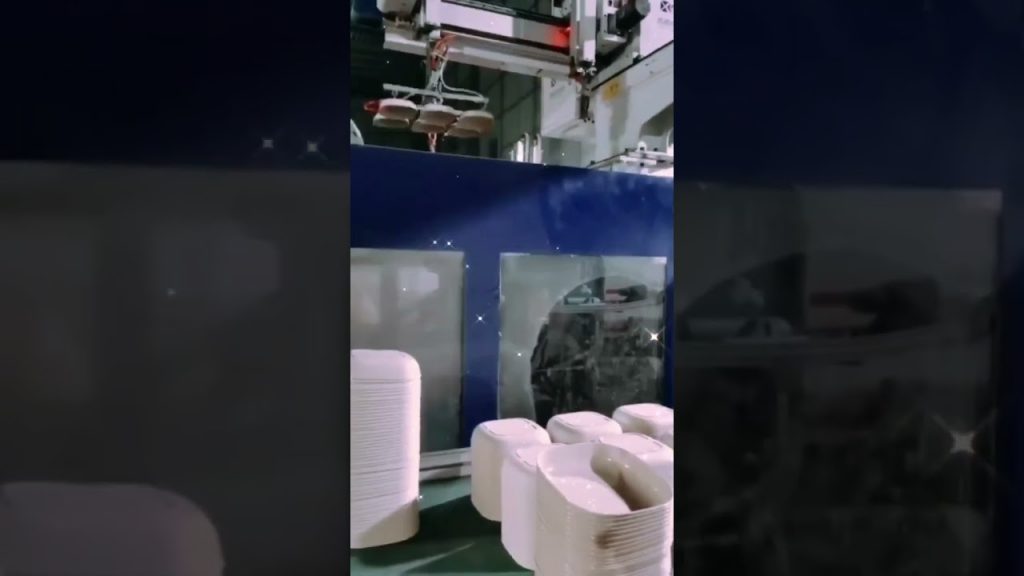

Case Study: Automatic Plastic Bowl Making Injection Molding Machine with Robots Six Cavities Running Factory

To illustrate the capabilities of Automatic Plastic Injection Machines, let’s take a look at a case study of a factory using an automatic plastic bowl making injection molding machine with robots. This factory specializes in the production of plastic bowls for the food packaging industry.

The factory utilizes a state-of-the-art automatic plastic injection machine equipped with six cavities. This allows them to produce six plastic bowls simultaneously, increasing their production capacity significantly. The machine is integrated with robots that assist in the molding process, ensuring smooth and efficient operation.

The use of an automatic plastic injection machine has transformed this factory’s production capabilities. The high efficiency and precision of the machine have resulted in a significant increase in output, meeting the growing demand for plastic bowls in the market. The integration of robots has also reduced labor costs and improved overall productivity.

Conclusion

Automatic Plastic Injection Machines are a game-changer in the manufacturing industry. Their ability to automate the injection molding process, coupled with their high efficiency and precision, makes them an invaluable asset for any business involved in plastic production. By investing in an automatic plastic injection machine, you can streamline your production process, reduce costs, and enhance the quality of your plastic products.

So, if you’re looking for a reliable and efficient solution for your plastic molding needs, consider investing in an Automatic Plastic Injection Machine. It’s a decision that will undoubtedly take your business to the next level.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant call-to-action statement or link] Plastic Injection Machine

“Efficient Plastic Bowl Making: Automated Injection Molding Machine with Robotic Assistance – 6 Cavities, Streamlining Factory Operations”