If you’re looking for complete packaging and palletizing solutions, look no further! In this article, we’ll dive into the world of automatic stretch wrapping machines and explore the benefits they can bring to your packaging process. Whether you’re a small business or a large-scale operation, an automatic stretch wrapping machine can revolutionize your packaging efficiency.

Before we dive into the details, let’s take a moment to understand what an automatic stretch wrapping machine is. Essentially, it’s a piece of equipment that automates the process of wrapping products or pallets with stretch film. This machine eliminates the need for manual wrapping, saving you time and effort.

One of the leading automatic stretch wrapping machines in the market is the Lantech QL Fully automatic stretch wrapping (InLine). This cutting-edge machine offers a range of features that make it a top choice for businesses of all sizes. With its advanced technology and user-friendly interface, the Lantech QL ensures a seamless and efficient packaging process.

So, what sets the Lantech QL apart from other stretch wrapping machines? Let’s take a closer look at its key features:

1. Fully Automatic Operation: The Lantech QL takes care of the entire packaging process from start to finish. You can simply load the products or pallets onto the machine, and it will automatically wrap them with precision and consistency.

2. Customizable Wrapping Programs: This machine allows you to customize the wrapping parameters according to your specific needs. You can adjust the film tension, number of wraps, and overlap to ensure optimal load stability and protection.

3. Advanced Film Carriage System: The Lantech QL is equipped with a state-of-the-art film carriage system that ensures smooth and accurate film application. It minimizes film waste and ensures maximum film stretch, resulting in cost savings for your business.

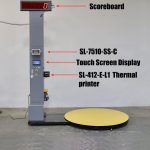

4. Intuitive Control Panel: The machine features an easy-to-use control panel that allows operators to set up and monitor the packaging process effortlessly. The interface provides real-time information and diagnostics, ensuring efficient operation and quick troubleshooting.

Now that we’ve explored the features of the Lantech QL, let’s discuss the benefits of incorporating an automatic stretch wrapping machine into your packaging process:

1. Increased Productivity: By automating the wrapping process, you can significantly increase your productivity. The machine works at a consistent speed, ensuring a faster turnaround time and reducing labor costs.

2. Improved Load Stability: Manual wrapping can often result in inconsistent film tension and inadequate load stability. With the Lantech QL, you can achieve consistent and uniform wrapping, ensuring that your products or pallets are securely packaged and protected during transportation.

3. Cost Savings: The Lantech QL’s advanced film carriage system helps minimize film waste, resulting in cost savings for your business. Additionally, the machine’s efficient operation reduces the need for manual labor, further reducing costs in the long run.

4. Enhanced Safety: Manual wrapping can be physically demanding and may pose a safety risk to your employees. By automating the process, you create a safer work environment and reduce the risk of injuries.

In conclusion, an automatic stretch wrapping machine like the Lantech QL is a game-changer for businesses in need of efficient and reliable packaging solutions. With its advanced features and user-friendly interface, this machine can streamline your packaging process, increase productivity, and reduce costs. Invest in an automatic stretch wrapping machine today and take your packaging efficiency to new heights.

Check the coil packing solution with a leading manufacturer for the professional solution just here! Stretch Wrapping Machine

“Efficient and Reliable Stretch Wrapping Solutions for Improved Packaging Processes”