Title: Advanced Industrial Food Packing Machine for Dry Food Packaging

Description:

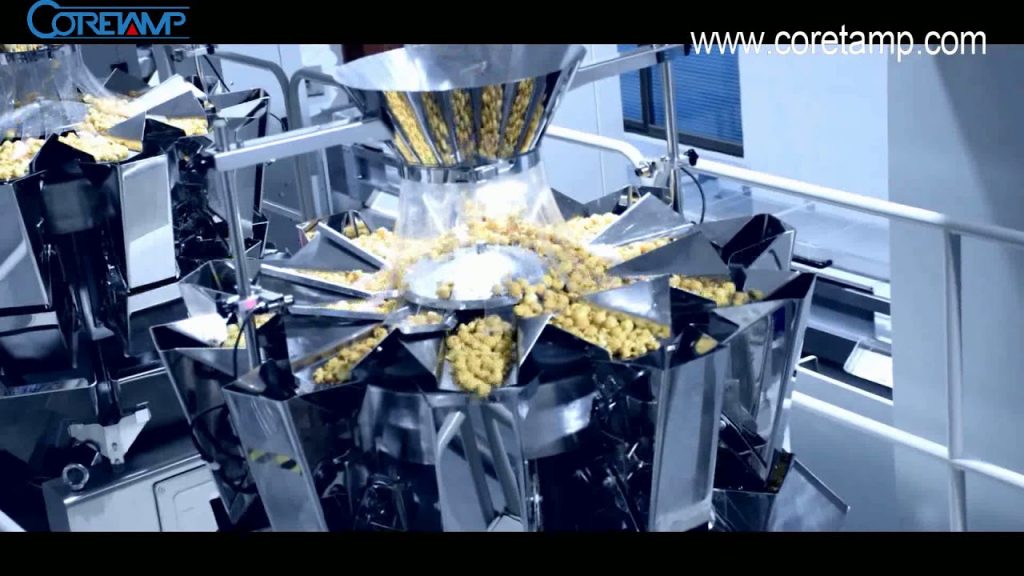

Welcome to our video showcasing the cutting-edge Industrial Food Packing Machine, specifically designed for efficient and precise dry food packaging. In this video, we will provide a comprehensive overview of this state-of-the-art automatic powder packaging machine and its suitability for various industries.

Web: [Link to the video]

Introduction:

Discover the unparalleled capabilities of our advanced Industrial Food Packing Machine, engineered to revolutionize the dry food packaging process. This powerful and versatile machine ensures optimal efficiency and accuracy, resulting in superior product quality and increased productivity.

Video Content:

In this video, we delve into the key features and benefits of our Industrial Food Packing Machine. We start by explaining its suitability for a wide range of industries, including the food and beverage, pharmaceutical, and chemical sectors. Whether you need to package powdered spices, flour, coffee, or other dry food products, this machine is tailor-made to meet your specific requirements.

Our expert team will guide you through the operation steps, highlighting the user-friendly interface and intuitive controls that enable seamless operation. Witness the machine’s exceptional speed and precision as it swiftly weighs, fills, and seals the packaging with utmost precision, ensuring consistent product quality and extended shelf life.

Key Highlights:

– High-speed packaging process for enhanced productivity

– Precise weighing and filling mechanisms for accurate portioning

– Versatile packaging options, including various bag sizes and materials

– Intelligent control system for easy operation and minimal downtime

– Robust construction for long-lasting performance and reliability

Call to Action:

If you found this video informative and inspiring, we encourage you to hit the like button, subscribe to our channel for more industry-leading content, and share this video with your network. Experience the future of dry food packaging with our Industrial Food Packing Machine.

Additional Tags and Keywords:

Industrial food packaging, dry food packing machine, automatic powder packaging machine, food packaging solutions, advanced packaging technology, efficient food packaging, precise powder filling, high-speed packaging machine, reliable packaging equipment.

Hashtags:

#IndustrialFoodPacking #DryFoodPackingMachine #PowderPackaging #AdvancedPackagingMachine

A tilter for a dry food packing machine is a mechanism that is used to rotate or tilt the products being packed. This is often done to ensure even distribution of the dry food within the packaging, optimize the filling process, and minimize the risk of damage to the products.

The tilter can be designed as a separate module or integrated into the existing dry food packing machine. It consists of several key components:

1. Conveyor Belt: The tilter is equipped with a conveyor belt that transports the dry food products to the tilting area. The belt is made of food-grade material to ensure hygiene and prevent contamination.

2. Tilting Mechanism: The tilting mechanism is responsible for rotating or tilting the products as they move along the conveyor belt. This can be achieved using a motorized system, such as a servo motor or stepper motor, which is controlled by a programmable logic controller (PLC).

3. Adjustable Angle: The tilter should have an adjustable angle feature to cater to different product requirements. This can be achieved by incorporating a pneumatic or hydraulic system that allows for easy angle adjustment.

4. Product Guides: To ensure stability and prevent product movement during tilting, the tilter should have product guides or side rails. These guides can be adjustable to accommodate various product sizes.

5. Safety Features: Safety is a crucial aspect of any machine. The tilter should be equipped with safety features like emergency stop buttons, sensors to detect any abnormalities, and safety interlocks to prevent accidents.

6. Control Panel: The control panel of the tilter should have an intuitive interface that allows operators to set the desired tilting angle, speed, and other parameters. This can be achieved through a touch screen or a series of buttons and knobs.

Overall, the tilter for a dry food packing machine plays a vital role in ensuring efficient and accurate packaging of dry food products. It enhances productivity, minimizes product damage, and improves the overall packaging process.Food Packing Machine

#dry #food #packing #machine #dry #food #packing #machine