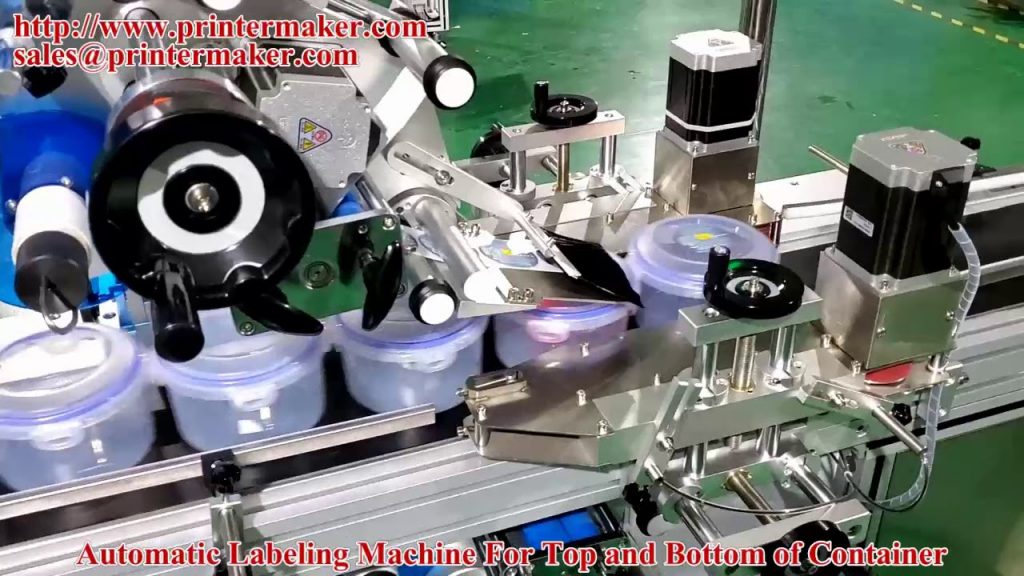

Title: Automatic Labeling Machine – Achieve Efficient and Precise Labeling for Top and Bottom of Containers

Description:

Welcome to our video showcasing the remarkable Automatic Labeling Machine. Designed to streamline your labeling process, this innovative machine ensures top-notch labeling accuracy for both the top and bottom of containers. With its user-friendly interface and cutting-edge technology, this labeling solution offers unmatched efficiency and reliability.

At [Company Name], we take pride in providing top-of-the-line labeling solutions, and our Automatic Labeling Machine is no exception. With its high-speed labeling capabilities and customizable settings, this machine guarantees seamless integration into your production line. Say goodbye to manual labeling errors and hello to efficient and precise labeling with our Automatic Labeling Machine.

In this video, we dive deep into the functionalities and features of the Automatic Labeling Machine. We will guide you through the step-by-step operation process, highlighting its key highlights and interesting facts. From its advanced labeling mechanism to its intuitive control panel, you will discover how this machine revolutionizes the labeling industry.

Our Automatic Labeling Machine is engineered to meet the diverse labeling needs of various industries, including food and beverage, pharmaceutical, and cosmetics. Whether you are labeling jars, bottles, or containers of different shapes and sizes, this machine ensures consistent and professional results every time.

To enhance your viewing experience, we have included informative subheadings that cover the different aspects of the Automatic Labeling Machine:

1. High-speed and Accurate Labeling: Discover how our machine guarantees precise and efficient labeling at an impressive speed.

2. Customizable Settings: Learn how to tailor the labeling process to meet your specific requirements, ensuring seamless integration into your production line.

3. Advanced Labeling Mechanism: Explore the cutting-edge technology behind the machine’s labeling mechanism, ensuring consistent and flawless labeling results.

4. User-friendly Interface: Experience the ease of operation with our intuitive control panel, designed to simplify the labeling process and minimize downtime.

We encourage you to like, subscribe, and share this video to spread the word about the Automatic Labeling Machine. If you are looking to enhance your labeling process and improve overall productivity, our machine is the perfect solution for you.

Additional Tags and Keywords: automatic labeling machine, labeling machine, container labeling, top and bottom labeling, efficient labeling, precise labeling, labeling technology, labeling solution

Hashtags: #AutomaticLabelingMachine #ContainerLabeling #EfficientLabeling #PreciseLabeling #LabelingSolution

Here’s a possible tilter for an automatic labeling machine designed to label both the top and bottom of containers:

1. Start by designing a sturdy and reliable conveyor system that can transport containers to the labeling station. Ensure that the conveyor system is adjustable to accommodate different sizes and shapes of containers.

2. Integrate sensors into the conveyor system to detect the arrival of containers at the labeling station. These sensors will trigger the tilter mechanism.

3. Develop a tilter mechanism that can efficiently and accurately flip the containers to expose their top and bottom surfaces for labeling. This mechanism should be capable of handling containers of various sizes and weights.

4. Incorporate a motorized arm or robotic arm into the tilter mechanism. This arm should be able to grip the containers securely and rotate them 180 degrees.

5. Implement a control system that coordinates the operation of the tilter mechanism with the labeling machine. This control system should ensure that the containers are properly flipped before the labeling process begins.

6. Integrate safety features into the tilter mechanism to prevent accidents or damage to the containers. These safety features may include emergency stop buttons, interlock switches, and protective barriers.

7. Conduct thorough testing to validate the performance and reliability of the tilter mechanism. Ensure that it can handle the expected workload and operate continuously without malfunctions.

8. Provide user-friendly controls and interfaces for operators to adjust the tilter mechanism according to the container specifications and labeling requirements.

9. Install the tilter mechanism in the automatic labeling machine, ensuring proper alignment with the labeling station.

10. Train operators on the safe and efficient use of the automatic labeling machine, including the tilter mechanism. Provide them with clear instructions and guidelines to prevent any accidents or disruptions in the labeling process.

11. Regularly inspect and maintain the tilter mechanism to ensure its continued functionality and reliability. Promptly address any issues or malfunctions that may arise during operation.

By following these steps, you can design and implement a tilter for an automatic labeling machine that effectively labels the top and bottom of containers.Labeling Machine

#Automatic #Labeling #Machine #Top #Bottom #Container