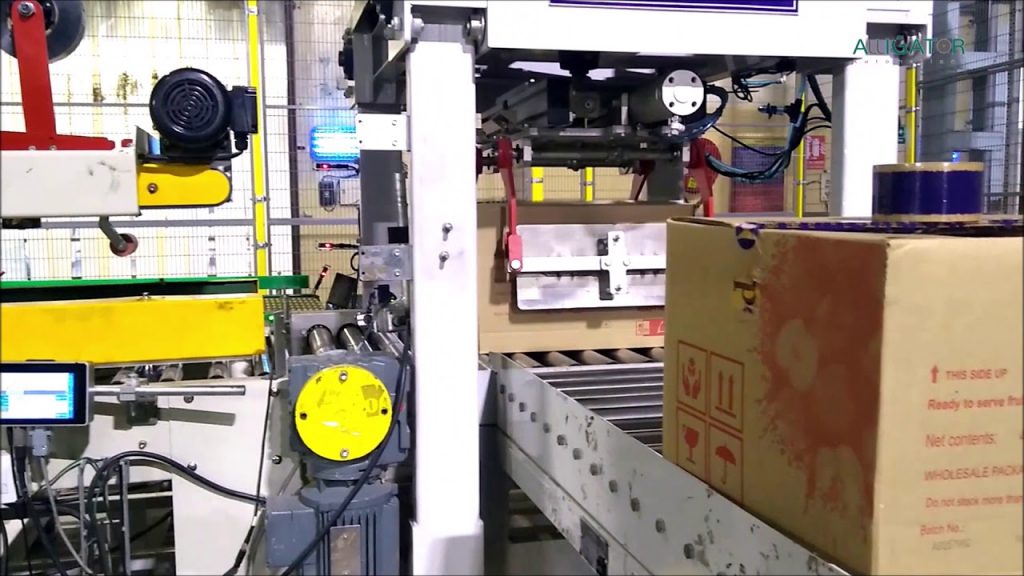

Automatic Packing System: Revolutionizing Case Packaging

Introduction:

In today’s fast-paced world, efficiency and productivity are key factors for businesses to thrive. This is particularly true in the manufacturing industry, where companies are constantly searching for ways to streamline their processes and optimize their operations. One area that has seen significant advancements in recent years is case packaging, thanks to the introduction of Automatic Packing Systems.

What is an Automatic Packing System?

An Automatic Packing System is a state-of-the-art machinery designed to automate the case packaging process. It eliminates the need for manual labor, reducing the risk of human errors and increasing overall efficiency. This system includes various components such as the Automatic Case Erector, Bottom Tapping, Robotic Box-in-Box Packing, and Automatic Case Sealing. Let’s take a closer look at each of these components and understand their role in revolutionizing the case packaging industry.

1. Automatic Case Erector:

The Automatic Case Erector is the first step in the case packaging process. It is responsible for automatically setting up the carton boxes, saving valuable time and reducing the need for manual labor. This component ensures that the boxes are properly formed and ready to be filled with products.

2. Bottom Tapping:

Once the carton boxes are erected, the Bottom Tapping component comes into play. It securely seals the bottom of the boxes, ensuring that they are sturdy and capable of withstanding transportation and storage. This not only enhances the overall packaging quality but also minimizes the risk of product damage during transit.

3. Robotic Box-in-Box Packing:

The Robotic Box-in-Box Packing component is a game-changer in the case packaging industry. It uses advanced robotic technology to intelligently pack products into the carton boxes. This ensures optimal space utilization, reducing packaging material waste and saving costs. Moreover, the precise and efficient packing process minimizes the chances of product damage, ensuring customer satisfaction.

4. Automatic Case Sealing:

The final step in the case packaging process is Automatic Case Sealing. This component ensures that the carton boxes are securely sealed, providing protection against dust, moisture, and tampering. It not only enhances the appearance of the packaged products but also facilitates easy handling during transportation and storage.

Benefits of Automatic Packing Systems:

The introduction of Automatic Packing Systems has brought about numerous benefits for businesses in the manufacturing industry. Let’s explore some of these benefits:

1. Increased Efficiency:

By automating the case packaging process, businesses can significantly increase their production output. Automatic Packing Systems work at a faster pace than manual labor, reducing the time required to package products. This increased efficiency allows companies to meet customer demands more effectively and stay ahead of their competition.

2. Cost Savings:

With an Automatic Packing System, companies can save on labor costs associated with manual packaging. The system requires minimal human intervention, reducing the need for a large workforce. Additionally, the precise packing process minimizes material waste, leading to cost savings in packaging materials.

3. Improved Product Quality:

Automatic Packing Systems ensure consistent and accurate packaging, reducing the chances of product damage during transit. This leads to improved product quality and customer satisfaction. Additionally, the secure sealing provided by the system protects products from external factors, maintaining their integrity.

4. Enhanced Safety:

By automating the case packaging process, companies can minimize the risk of workplace accidents and injuries. Manual packaging involves repetitive movements and heavy lifting, which can lead to strain and injuries for workers. Automatic Packing Systems eliminate these risks, creating a safer working environment.

Conclusion:

The introduction of Automatic Packing Systems has revolutionized the case packaging industry. With components such as Automatic Case Erectors, Bottom Tappers, Robotic Box-in-Box Packing, and Automatic Case Sealers, these systems offer increased efficiency, cost savings, improved product quality, and enhanced safety. As businesses strive to optimize their operations and keep up with customer demands, investing in an Automatic Packing System has become a necessity.

Check the coil packing solution with leading manufacturers for professional solutions. Packing System

“Efficient Case Packaging System: Streamlining Operations with Automated Case Erector and Packing Automation”