Title: High-Speed Automatic Packing Line for Bread: Rotary Packaging Machine Revolutionizing the Biscuit Packaging Industry

Description:

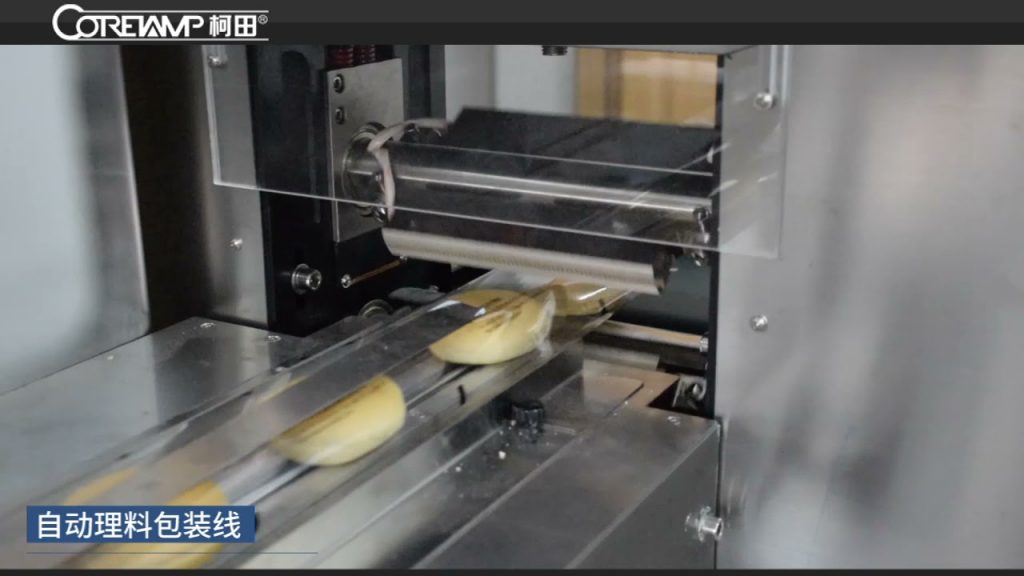

Welcome to our YouTube video showcasing the incredible capabilities of the High-Speed Automatic Packing Line for Bread. In this video, we dive deep into the world of bread and biscuit packaging, specifically focusing on the innovative rotary packaging machine model. Prepare to be amazed as we explore the various features, benefits, and operation steps of this cutting-edge automatic packaging machine.

Introduction:

Join us as we unveil the revolutionizing High-Speed Automatic Packing Line designed specifically for bread and biscuits. This video serves as a comprehensive guide, providing valuable insights into the intricate process of packaging these delectable treats. From enhancing efficiency to ensuring product quality, this automatic packaging line is set to transform the industry.

Video Content:

1. Exploring the Bread/Biscuit Packaging Industry:

– Overview of the importance of efficient packaging for bread and biscuits.

– Understanding the challenges faced by manufacturers in this industry.

2. Introducing the High-Speed Automatic Packing Line:

– A detailed overview of the rotary packaging machine model.

– Highlighting its key features and capabilities.

– Advantages of utilizing this automatic packaging solution.

3. Operation Steps of the Rotary Packaging Machine:

– Step-by-step demonstration of the packaging process.

– Understanding the machine’s functionality and control mechanisms.

– Efficient handling of various packaging materials and sizes.

4. Benefits and Highlights:

– Increased production speed and efficiency.

– Maintaining product freshness and quality.

– Minimizing human errors and ensuring accuracy.

– Customizable packaging options for branding and marketing.

Call to Action:

If you found this video informative and captivating, we encourage you to hit the “Like” button and subscribe to our channel for more exciting content. Share this video with your friends and colleagues who are interested in the bread and biscuit packaging industry.

Additional Tags and Keywords: High-Speed Automatic Packing Line, Automatic Packaging Machine, Bread Packaging, Biscuit Packaging, Rotary Packaging Machine, Packaging Industry.

Hashtags: #AutomaticPackingLine #BreadPackaging #BiscuitPackaging #RotaryPackagingMachine #PackagingIndustry

Here is a sample tilter for a high-speed automatic packaging line for bread packing using a rotary packing mechanism:

Title: High-Speed Automatic Packaging Line Tilter for Bread Packing Rotary Packing

1. Introduction:

– Explain the purpose of the tilter in the high-speed automatic packaging line for bread packing.

– Provide an overview of the rotary packing mechanism.

– State the objectives of the tilter.

2. Equipment and Components:

– List and describe the equipment and components involved in the tilter, such as motors, sensors, actuators, and controllers.

– Discuss the specifications and capabilities of each component.

3. Operating Principle:

– Explain how the tilter works in conjunction with the rotary packing mechanism.

– Describe the sequence of operations involved in tilting the bread packets.

4. Tilter Control System:

– Detail the control system responsible for controlling the tilter.

– Discuss the feedback and control loops involved in maintaining stability and accuracy.

– Explain how the control system integrates with the overall packaging line.

5. Safety Measures:

– Highlight the safety measures implemented in the tilter system to ensure operator safety and prevent accidents.

– Discuss emergency stop mechanisms and safety interlocks.

6. Performance and Efficiency:

– Present the performance metrics used to measure the efficiency of the tilter.

– Discuss factors that affect the tilter’s performance, such as speed, precision, and reliability.

– Provide data or case studies demonstrating the tilter’s performance in terms of throughput and accuracy.

7. Maintenance and Troubleshooting:

– Describe the maintenance requirements for the tilter.

– Provide guidelines for troubleshooting common issues that may arise during operation.

– Explain the importance of regular maintenance and potential consequences of neglecting it.

8. Integration with the Packaging Line:

– Discuss the integration of the tilter with the overall high-speed automatic packaging line.

– Explain how the tilter interfaces with upstream and downstream equipment.

– Describe any communication protocols or interfaces used for seamless integration.

9. Future Developments and Upgrades:

– Discuss potential future developments or upgrades for the tilter system.

– Consider advancements in automation, robotics, or sensor technology that could enhance the tilter’s performance.

10. Conclusion:

– Summarize the key points discussed in the tilter for the high-speed automatic packaging line for bread packing using a rotary packing mechanism.

– Emphasize the importance of the tilter in achieving efficient and accurate bread packaging.

– Highlight the benefits of implementing a high-speed automatic packaging line with a reliable tilter system. coil packing line

#High #Speed #Automatic #Packaging #Line #Bread #packing #Rotary #packing