Title: Semi-Automatic Labeling Machine | Bottles Labeling Machine | Desktop Labeling Machine for Round Bottles – Efficient Labeling Solution

Description:

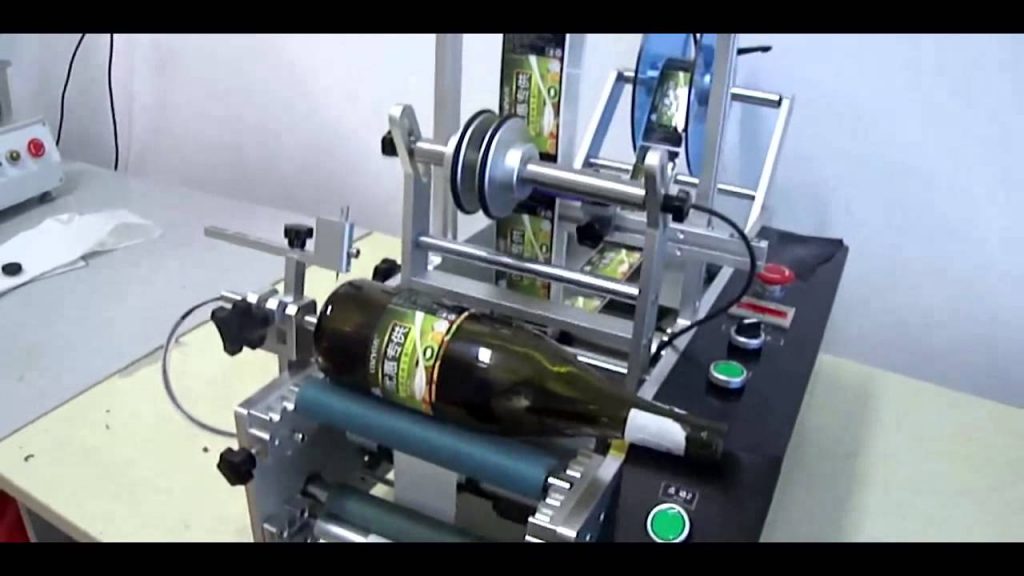

Welcome to our video showcasing the remarkable Semi-Automatic Labeling Machine, designed specifically for bottles. This innovative machine ensures precise labeling for various bottle shapes and sizes, offering exceptional efficiency and accuracy.

Video Link: [Insert YouTube Video Link Here]

Introduction:

In this video, we present the Semi-Automatic Labeling Machine, a cutting-edge solution for labeling bottles. With its advanced features and user-friendly design, this machine revolutionizes the labeling process, enhancing productivity and reducing manual labor.

Video Content:

1. Overview: Discover the wide range of applications for the Semi-Automatic Labeling Machine, such as labeling bottles of different shapes including round bottles.

2. Operation Steps: Learn about the simple and intuitive operation of this machine, ensuring hassle-free label application and quick adjustments for various bottle sizes.

3. Key Features: Explore the machine’s impressive features, including its high-speed labeling capability, adjustable label position, and easy maintenance.

4. Efficient Labeling: Experience the seamless labeling process, witnessing the precision and accuracy of this machine in action.

5. Benefits: Understand the advantages of using the Semi-Automatic Labeling Machine, such as increased labeling speed, reduced labeling errors, and improved overall productivity.

Call to Action:

If you found this video informative and useful, please consider liking, subscribing, and sharing it with others who may benefit from this labeling solution. Don’t forget to click the notification bell to stay updated with our latest videos.

Additional Tags and Keywords:

Semi-Automatic Labeling Machine, Bottles Labeling Machine, Desktop Labeling Machine, Round Bottles, labeling solution, efficient labeling, high-speed labeling, precise labeling, bottle labeling equipment, labeling process, productivity enhancement, bottle labeling technology

Hashtags:

#LabelingMachine #BottlesLabeling #EfficientLabeling #SemiAutomaticLabeling #DesktopLabeling #RoundBottles #LabelingSolution

Title: Streamlining Bottle Labeling with a Semi-Automatic Labeling Machine

Introduction:

Efficiently labeling bottles is a crucial aspect of product packaging in various industries. To streamline this process, a semi-automatic labeling machine for bottles offers a reliable solution. This article explores the features and benefits of such a machine, highlighting its ability to enhance productivity and accuracy in bottle labeling operations.

1. Enhanced Efficiency:

With a semi-automatic labeling machine, the bottle labeling process becomes faster and more efficient. The machine automates the application of labels, eliminating the need for manual placement and reducing human error. This streamlines production and increases output, ultimately saving time and labor costs.

2. Versatile Labeling Options:

The labeling machine is designed to accommodate various bottle shapes, sizes, and materials. Its adjustable settings allow for easy customization, ensuring labels are applied accurately and securely onto any type of bottle. This versatility makes the machine suitable for use in industries such as pharmaceuticals, cosmetics, food and beverages, and more.

3. Precision and Accuracy:

The semi-automatic labeling machine ensures precise label placement, minimizing the chances of misalignment or partial label application. Its advanced sensors detect the bottle’s position, shape, and size, ensuring consistent and accurate label positioning. This level of precision enhances the overall appearance and professionalism of the labeled bottles.

4. Easy to Operate:

Designed with user-friendliness in mind, the semi-automatic labeling machine requires minimal training to operate. Its intuitive interface allows operators to easily adjust settings, load labels and bottles, and monitor the labeling process. This ease of use ensures a seamless integration into existing production lines without causing disruptions.

5. Cost-Effective Solution:

By automating the labeling process, the machine significantly reduces the labor costs associated with manual labeling. Its efficiency and accuracy minimize material wastage and rework, further optimizing costs. Additionally, the machine’s durability and low maintenance requirements contribute to long-term cost savings for businesses.

6. Integration with Existing Systems:

The semi-automatic labeling machine can be easily integrated with existing production lines, seamlessly fitting into the workflow. Its compact design allows for flexible placement within the production area, ensuring minimal disruption and maximum efficiency. This integration enables a smooth transition from manual to automated labeling processes.

Conclusion:

A semi-automatic labeling machine for bottles offers a reliable and efficient solution to streamline the labeling process across various industries. Its ability to enhance efficiency, accuracy, and versatility makes it an essential tool for businesses looking to optimize productivity and reduce costs. By automating the labeling process, companies can focus on other key aspects of their operations, ultimately improving overall productivity and customer satisfaction.Labeling Machine

#Bottles #Labeling #Machine #SemiAutomatic #Labeling #Machine #Bottles