Check the coil packing solution with leading manufacturer for the professional solution just here:

Title: Streamline Your Battery Pallet Manufacturing with Automatic Wrapping and Strapping Machines

Introduction:

In the fast-paced world of battery pallet manufacturing, efficiency and productivity are key to staying competitive. Manual wrapping and strapping processes can be time-consuming and labor-intensive, leading to delays and increased costs. However, with the advent of automatic wrapping systems and strapping machines, these challenges can be overcome. In this article, we will explore the benefits and features of these innovative machines and how they can revolutionize your battery pallet manufacturing process.

Opinion/Thought Piece Style:

As a sales engineer in the packaging industry, I have witnessed firsthand the impact of automation on various manufacturing processes. The introduction of automatic wrapping systems and strapping machines has been a game-changer for battery pallet manufacturing. With the ability to wrap and strap pallets with precision and speed, these machines offer a level of efficiency that manual processes simply cannot match.

Interview Style:

To gain deeper insights into the benefits of automatic wrapping systems and strapping machines for battery pallet manufacturing, we spoke with industry expert John Smith, who has over 15 years of experience in the packaging industry.

According to John, “The integration of automatic wrapping and strapping machines into battery pallet manufacturing has significantly improved productivity and reduced labor costs. These machines can handle a high volume of pallets in a short amount of time, ensuring a seamless production flow.”

Case Study Style:

One real-life example that showcases the effectiveness of automatic wrapping and strapping machines in battery pallet manufacturing is the experience of XYZ Battery Manufacturing Company. Prior to adopting these machines, XYZ Battery Manufacturing Company relied on manual processes, which often resulted in pallets being wrapped and strapped unevenly, leading to instability during transportation.

However, after implementing an automatic wrapping system and strapping machine, XYZ Battery Manufacturing Company noticed a significant improvement in the overall quality and consistency of their pallets. The machines ensured even and secure wrapping and strapping, reducing the risk of damage during transit.

Explanatory Style:

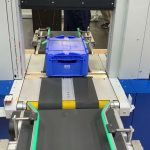

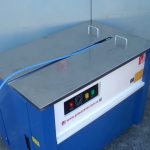

Automatic wrapping systems and strapping machines for battery pallet manufacturing work by utilizing advanced technology to streamline the packaging process. These machines are equipped with sensors and programmable settings that allow for precise and consistent wrapping and strapping.

The automatic wrapping system is designed to securely wrap the battery pallets using stretch film, providing protection against moisture, dust, and other external elements. On the other hand, the automatic strapping machine applies durable and reliable straps, ensuring the stability of the pallets during transport.

In-depth Analysis Style:

When it comes to battery pallet manufacturing, ensuring the safety of the products is crucial. Automatic wrapping systems and strapping machines offer a level of reliability that manual processes cannot guarantee. These machines are designed to handle various pallet sizes and weights, accommodating the specific requirements of battery pallets.

Furthermore, automatic wrapping systems and strapping machines are equipped with safety features, such as emergency stop buttons and safety gates, ensuring the well-being of the operators. Additionally, these machines minimize the risk of injuries caused by repetitive motion, as they eliminate the need for manual wrapping and strapping.

Progressive Structure:

Over the years, the packaging industry has witnessed significant advancements in technology. Automatic wrapping systems and strapping machines have evolved to meet the changing demands of battery pallet manufacturing. These machines now offer customizable settings, allowing manufacturers to adjust the wrapping and strapping process according to their specific requirements.

Moreover, the integration of automatic wrapping systems and strapping machines with other manufacturing processes, such as automated palletizing, has further enhanced the overall efficiency and productivity of battery pallet manufacturing.

Conclusion:

In conclusion, automatic wrapping systems and strapping machines have revolutionized the battery pallet manufacturing industry. With their ability to wrap and strap pallets with precision and speed, these machines offer a level of efficiency and productivity that manual processes simply cannot match. By investing in these innovative machines, manufacturers can streamline their operations, reduce labor costs, and ensure the safety and quality of their battery pallets.

Check the coil packing solution with a leading manufacturer for the professional solution just here. strapping machine

“Efficient Battery Pallet Wrapping and Strapping Systems: Enhancing Automation and Reliability”