Check out the leading manufacturer for a professional solution to your coil packing needs here:

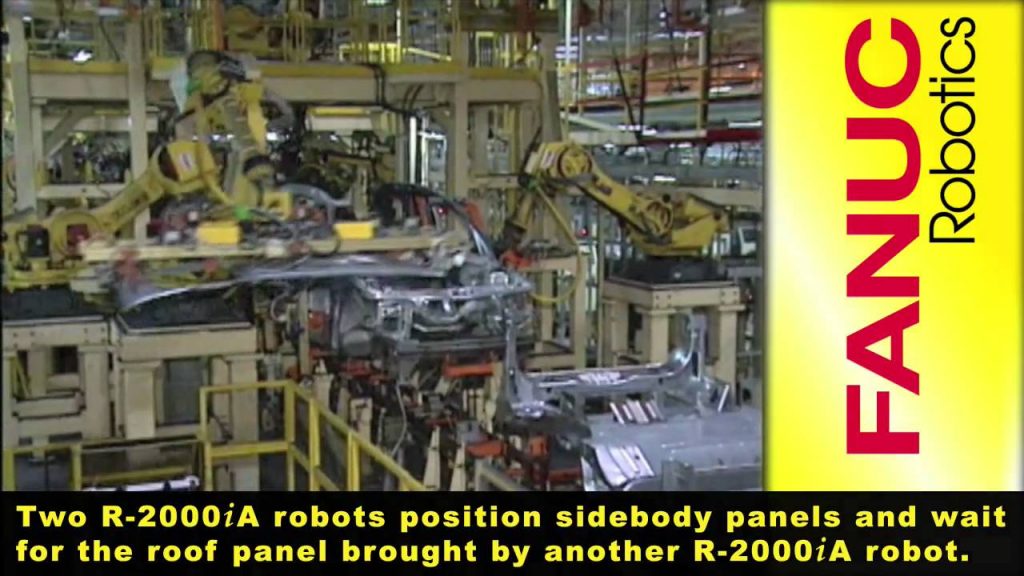

The automotive industry is constantly evolving, with advancements in technology and automation revolutionizing the assembly process. One key player in this transformation is the Industrial Automation Robots, specifically the FANUC R-2000iA robots. In this video, we will explore the fascinating world of automotive assembly and how these robots are shaping the future of manufacturing.

The assembly line is the heart of any automotive production facility. It is where various components come together to create a finished product. Traditionally, this process relied heavily on manual labor, which was time-consuming and prone to errors. However, with the introduction of Industrial Automation Robots like the FANUC R-2000iA, the assembly process has become more efficient and reliable.

These state-of-the-art robots are designed to perform a wide range of tasks, from welding and painting to material handling and assembly. Equipped with advanced sensors and precision controls, they can work with incredible speed and accuracy, ensuring consistent quality throughout the production process. Their versatility allows them to adapt to different assembly requirements, making them ideal for the automotive industry.

The FANUC R-2000iA robots work in harmony with human workers, creating a collaborative environment where both can thrive. By taking over repetitive and physically demanding tasks, these robots free up human workers to focus on more complex and creative aspects of the assembly process. This not only improves productivity but also enhances worker safety and job satisfaction.

Furthermore, the use of Industrial Automation Robots in automotive assembly has several other benefits. For instance, they can significantly reduce production costs by minimizing waste, optimizing energy consumption, and maximizing overall efficiency. Additionally, these robots have a smaller footprint compared to traditional assembly methods, making them ideal for space-constrained manufacturing facilities.

The integration of Industrial Automation Robots into the automotive assembly process has revolutionized the industry. It has enabled manufacturers to achieve higher productivity, improved quality control, and cost savings. As technology continues to advance, we can expect even more innovative solutions to enhance the assembly process further.

In conclusion, the FANUC R-2000iA robots have transformed the automotive assembly process, bringing efficiency, precision, and automation to the industry. Their ability to work alongside human workers creates a collaborative and productive environment. With the continuous advancements in Industrial Automation Robots, the future of automotive assembly looks promising.

Check out the leading manufacturer for a professional solution to your coil packing needs here: Industrial Robot

“Revolutionizing Automotive Assembly: The Power of R-2000iA Robotics for Industrial Automation Efficiency”