Do you want to learn more about the fascinating world of injection molding plastic products and the advanced technology behind it? Look no further! In this YouTube video article, we will explore the revolutionary Automatic Plastic Injection Machine and its role in the process of runner gate automatic ultrasonic separation vibration drop.

Introduction:

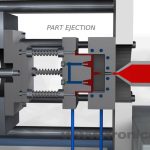

Injection molding is a widely used manufacturing process for producing plastic products. It involves injecting molten plastic into a mold cavity, allowing it to cool and solidify, and then ejecting the finished product. This process requires precision and efficiency, which is where the Automatic Plastic Injection Machine comes into play.

The Automatic Plastic Injection Machine:

The Automatic Plastic Injection Machine is a state-of-the-art device designed to streamline the injection molding process. With its advanced automation features, this machine reduces labor costs and ensures consistent quality in the final products. It is equipped with cutting-edge technology that allows for precise control over the injection speed, pressure, and temperature, resulting in superior finished products.

Runner Gate Automatic Ultrasonic Separation Vibration Drop:

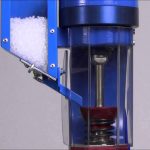

One crucial aspect of the injection molding process is the separation of the runner gate from the final product. The runner gate is the channel through which the molten plastic flows into the mold cavity. Traditionally, this separation was done manually, which was time-consuming and labor-intensive. However, with the runner gate automatic ultrasonic separation vibration drop machine, this process has been revolutionized.

This machine utilizes ultrasonic vibrations to separate the runner gate from the final product automatically. It eliminates the need for manual intervention, reducing the risk of errors and increasing overall productivity. The ultrasonic vibrations ensure a clean and precise separation, resulting in high-quality finished products.

Advantages of the Automatic Plastic Injection Machine and Runner Gate Automatic Ultrasonic Separation Vibration Drop:

1. Increased Efficiency: The automation features of the Automatic Plastic Injection Machine significantly improve production efficiency, reducing cycle times and increasing output.

2. Cost-effectiveness: By minimizing labor requirements, these machines help reduce production costs, making them an economical choice for manufacturers.

3. Consistent Quality: The precise control over injection parameters ensures consistent quality in the final products, meeting the strictest industry standards.

4. Time-saving: The automatic runner gate separation saves valuable time, allowing for faster production and quicker turnaround times.

In conclusion, the Automatic Plastic Injection Machine, coupled with the runner gate automatic ultrasonic separation vibration drop machine, offers a cutting-edge solution for the injection molding process. These advanced technologies bring efficiency, cost-effectiveness, and consistent quality to the manufacturing industry.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Plastic Injection Machine

“Efficient Separation of Runner Gates: Automatic Vibration Drop Machine for Plastic Injection Molding”