Title: Automatic Packing Line Reviews | Crepes/Thin Pancake Packaging Solution | High-Speed and Cost-Effective

Description:

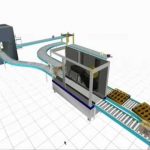

Welcome to our comprehensive review of Automatic Packing Line solutions for crepes and thin pancakes. In this video, we will explore the efficient and innovative crepes flow packaging machine, also known as the pancake pack machine, which offers a high-speed packaging solution. By implementing this automated packaging system, businesses can significantly increase their profits while reducing costs and minimizing product waste.

[Heading 1: Introduction]

In the fast-paced food industry, the demand for ready-to-consume products like crepes and thin pancakes is continuously growing. As a result, efficient packaging solutions have become crucial to meet market demands effectively. Our automatic packing line review focuses on the crepes flow packaging machine, a cutting-edge solution designed to boost productivity, reduce manual labor, and improve overall packaging efficiency.

[Heading 2: Crepes/Thin Pancake Automatic Packaging Solution]

The crepes flow packaging machine is a state-of-the-art solution specifically designed for the automatic packaging of crepes and thin pancakes. With its high-speed capabilities, this machine ensures efficient and consistent packaging, allowing businesses to meet customer demands swiftly.

[Heading 3: Increased Profitability and Waste Reduction]

Implementing the crepes flow packaging machine can lead to a significant increase in profitability for businesses. By automating the packaging process, companies can save costs associated with manual labor and reduce product waste. This efficient solution ensures that each crepe or pancake is perfectly packaged, minimizing the risk of spoilage or damage.

[Heading 4: Key Features and Benefits]

– High-Speed Packaging: The crepes flow packaging machine can handle a large volume of crepes or thin pancakes in a short amount of time, ensuring quick and efficient packaging.

– Precise Packaging: This automated solution guarantees consistent and precise packaging, maintaining the quality and presentation of each product.

– Waste Reduction: By eliminating manual packaging, businesses can significantly reduce product waste and minimize losses.

– Cost Savings: The automated packaging process reduces the need for manual labor, leading to cost savings and improved profitability.

– Improved Shelf Life: Properly packaged crepes and thin pancakes have an extended shelf life, reducing the risk of spoilage and ensuring customer satisfaction.

[Heading 5: Call to Action]

If you found this video informative and helpful, please consider liking, subscribing, and sharing it with others in the food industry. Stay updated with the latest packaging solutions and techniques by subscribing to our channel.

[Additional Tags and Keywords]

Automatic Packing Line Reviews, Crepes flow packaging machine, Pancake pack machine, Automatic packaging solution, Thin pancake packaging, High-speed packaging, Cost-effective packaging, Increased profitability, Product waste reduction, Innovative packaging solutions, Food industry packaging.

[Hashtags]

#AutomaticPackingLine #CrepesPackagingSolution #HighSpeedPackaging #CostEffectivePackaging #PancakePackMachine #ProductWasteReduction #IncreasedProfitability #InnovativePackaging

Title: Automated Crepes Packaging Machine: Revolutionizing Thin Pancake Packaging

Introduction:

In recent years, the demand for crepes and thin pancakes has been steadily increasing, leading to a need for efficient and automated packaging solutions. To meet this demand, we present the Crepes Flow Packaging Machine – an innovative pancake pack machine that offers a seamless and automated packaging process. This article explores the features and benefits of this advanced technology, revolutionizing the packaging of crepes and thin pancakes.

1. Streamlined Packaging Process:

The Crepes Flow Packaging Machine simplifies the packaging process, eliminating the need for manual labor. With its automated system, it efficiently assembles, fills, and seals the packaging, reducing production time and costs. This enables businesses to meet high-volume demands while maintaining consistency in quality.

2. Versatile Packaging Options:

This cutting-edge machine caters to a wide range of crepes and thin pancake sizes, accommodating various thicknesses and diameters. The packaging can be tailored to individual requirements, offering options for single or multiple crepes per pack. This versatility ensures that businesses can cater to diverse customer preferences.

3. Enhanced Product Presentation:

The machine’s packaging system ensures that crepes and thin pancakes are displayed in an appealing and presentable manner. The automated process maintains the product’s shape, preventing any deformities during packaging. Brands can take advantage of this feature to enhance their product’s visual appeal and attract customers.

4. Hygienic and Food Safety Standards:

Maintaining the highest food safety standards is crucial in the food industry. The Crepes Flow Packaging Machine ensures a hygienic packaging process, minimizing the risk of contamination. Its automated system minimizes human contact, reducing the chances of cross-contamination and ensuring the safety and quality of the packaged products.

5. Increased Efficiency and Cost Savings:

By automating the packaging process, businesses can significantly increase their overall efficiency. The machine’s high-speed operation allows for rapid packaging, maximizing productivity and reducing labor costs. Furthermore, the precise portion control feature eliminates product wastage, contributing to cost savings and increased profitability.

6. User-Friendly Interface:

The Crepes Flow Packaging Machine boasts a user-friendly interface, making it easy to operate and maintain. The intuitive control panel allows operators to adjust settings, monitor production, and address any issues quickly. Its simple design ensures that even non-technical staff can operate the machine with minimal training, saving time and resources.

Conclusion:

The Crepes Flow Packaging Machine offers a comprehensive solution for automating the packaging process of crepes and thin pancakes. With its streamlined operation, versatile packaging options, and focus on food safety, this innovative machine revolutionizes the pancake packaging industry. By investing in this cutting-edge technology, businesses can enhance productivity, reduce costs, and meet the growing demand for crepes and thin pancakes effectively. coil packing line

#Crepesthin #pancake #automatic #packaging #solutioncrepes #flow #packaging #machine #pancake #pack #machine