Title: “Revolutionize Your Food Packaging Process with the Skywin Automatic Biscuit Production Line”

Description:

Introduction:

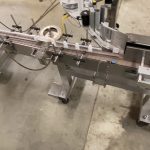

Welcome to our video showcasing the cutting-edge Automatic Food Packing Line and the Skywin Automatic Biscuit Production Line with On-edge Packing technology. In this video, we will provide an in-depth overview of these innovative systems, highlighting their features and benefits for businesses in the food industry.

Video Content:

The Automatic Food Packing Line is a game-changer in the food packaging industry. Designed to streamline the packing process, this advanced system combines efficiency and precision, ensuring fast and accurate packaging of various food products. With its automatic biscuit sorting, feeding, and packing capabilities, this line offers a comprehensive solution for businesses of all sizes.

The Skywin Automatic Biscuit Production Line takes packaging to the next level with its On-edge Packing technology. This unique feature allows biscuits to be packed in an upright position, minimizing the risk of breakage and ensuring the product’s integrity. With this innovative system, businesses can enhance their packaging efficiency and deliver high-quality biscuits to their customers.

Key Highlights:

– Efficient biscuit sorting: The automatic sorting feature of these production lines eliminates the need for manual sorting, saving time and reducing labor costs.

– Precise feeding system: The advanced feeding mechanism ensures a consistent flow of biscuits, minimizing disruptions in the production process.

– On-edge packing: The On-edge Packing technology in the Skywin Automatic Biscuit Production Line ensures the safe and secure packaging of biscuits, reducing breakage and preserving product quality.

– Comprehensive packing system: Both production lines offer a complete packing solution, encompassing sorting, feeding, and packaging, allowing businesses to optimize their operations.

Operation Steps:

1. Biscuit Sorting: The automatic sorting system efficiently categorizes biscuits based on size, shape, or any other predetermined criteria.

2. Feeding: The precise feeding mechanism ensures a continuous flow of biscuits, preventing bottlenecks in the production process.

3. Packing: The biscuits are packed using the On-edge Packing technology, ensuring their safety and minimizing breakage.

4. Quality Control: The production lines are equipped with quality control measures to ensure that only the highest-quality biscuits are packaged.

5. Output: The packed biscuits are ready for distribution, meeting the demands of customers and ensuring their satisfaction.

Call to Action:

If you want to revolutionize your food packaging process and enhance your biscuit production, the Automatic Food Packing Line and the Skywin Automatic Biscuit Production Line with On-edge Packing technology are the solutions you need. Don’t forget to like, subscribe, and share this video to stay updated with the latest innovations in the food industry.

Additional Tags and Keywords:

food packaging, biscuit production, automatic sorting, feeding system, On-edge Packing, packaging efficiency, biscuit quality, innovative technology, food industry

Hashtags:

#FoodPackaging #BiscuitProduction #AutomaticSorting #OnEdgePacking #Innovation #FoodIndustry

Sure! Here’s a sample tilter for the Skywin Automatic Biscuit Production Line with On Edge Packing Line:

1. Start by ensuring that the automatic biscuit production line is properly set up and running smoothly.

2. Position the on edge packing line adjacent to the biscuit production line, with enough space for the tilter equipment.

3. Install the tilter equipment at a suitable location on the on edge packing line, ensuring it is securely mounted and stable.

4. Connect the tilter equipment to the power supply, making sure to follow the manufacturer’s instructions for electrical connections.

5. Adjust the settings on the tilter equipment, such as tilt angle and speed, according to the desired production requirements.

6. Activate the tilter equipment, either manually or through an automated control system, to start the tilting process.

7. As the biscuits are produced on the production line, they should be directed towards the tilter equipment.

8. The tilter equipment will then tilt the biscuits onto their edges, aligning them for the on edge packing process.

9. Ensure that the biscuits are properly aligned and spaced on the on edge packing line, ready for packaging.

10. Coordinate the timing between the biscuit production line and the on edge packing line to ensure a continuous and efficient production flow.

11. Monitor the tilter equipment regularly for any issues or malfunctions, and perform necessary maintenance and cleaning as required.

12. Train the operators on how to operate and maintain the tilter equipment, emphasizing safety precautions and proper handling techniques.

13. Continuously optimize and improve the tilter process by analyzing production data, identifying bottlenecks, and implementing appropriate adjustments.

14. Regularly inspect and evaluate the performance of the tilter equipment, considering feedback from operators and making necessary improvements if needed.

By following these steps, the tilter for the Skywin Automatic Biscuit Production Line with On Edge Packing Line can effectively tilt the biscuits onto their edges, facilitating the on edge packing process and ensuring efficient production. coil packing line

#Skywin #Automatic #Biscuit #Production #Line #edge #Packing #line