Check out the coil packing solution with the leading industrial robot manufacturers for a professional solution right here:

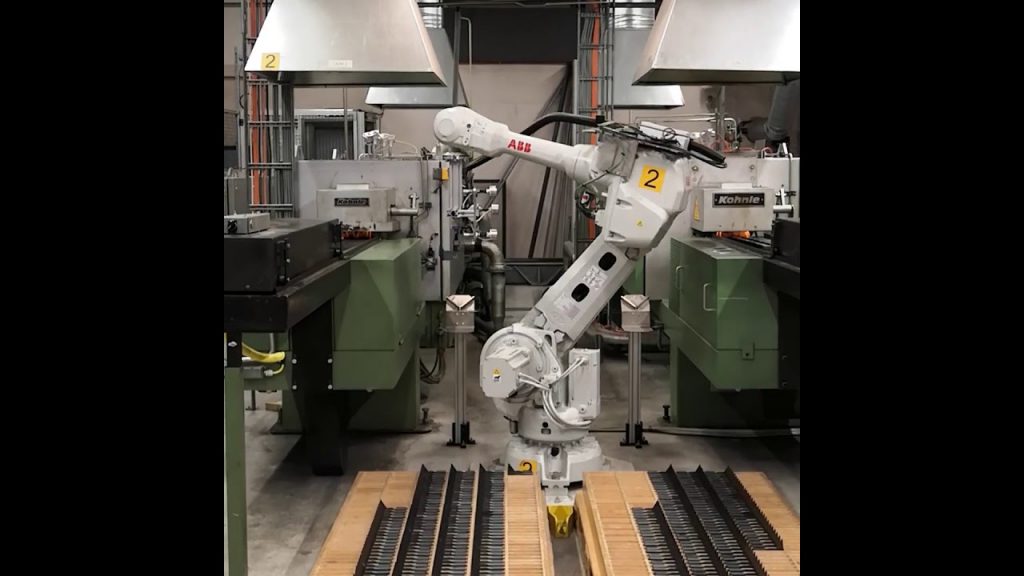

In today’s fast-paced manufacturing industry, the use of robots has revolutionized the way we operate. These automated machines have become an integral part of our factory, performing numerous repetitive tasks with precision and efficiency. One of our main robotics suppliers is ABB, who has played a crucial role in helping us build a state-of-the-art facility.

At our factory, we rely on the expertise of industrial robot manufacturers to streamline our operations and ensure optimal productivity. The collaboration with ABB has allowed us to enhance our manufacturing processes and achieve exceptional results in terms of quality and output.

One particular area where robots have made a significant impact is in our hardening shop. This critical stage in the production process requires precise control and uniformity to ensure the durability and strength of our products. With the help of ABB’s advanced robotic systems, we have been able to automate this process, eliminating human error and ensuring consistent results every time.

The robots in our hardening shop are equipped with cutting-edge technology that enables them to handle the complex tasks involved in the hardening process. From controlling the temperature and timing to monitoring the quality of the output, these robots have proven to be indispensable in maintaining the highest standards in our production.

The partnership with ABB and other industrial robot manufacturers has not only improved our operational efficiency but has also had a positive impact on our workforce. By automating repetitive tasks, we have been able to free up our employees to focus on more complex and value-added activities that require human expertise. This has not only increased job satisfaction but has also contributed to a more skilled and motivated workforce.

The integration of robots into our factory has not been without its challenges. As with any new technology, there was a learning curve involved in adopting and optimizing the use of robots in our processes. However, with the support and expertise of ABB, we were able to overcome these obstacles and fully leverage the benefits of automation.

Looking ahead, the future of manufacturing undoubtedly lies in the hands of industrial robot manufacturers. With advancements in artificial intelligence and machine learning, we can expect even greater capabilities and efficiencies from these automated systems. From increased productivity to improved safety and quality, the potential for growth and innovation is limitless.

In conclusion, the collaboration with industrial robot manufacturers, such as ABB, has transformed our factory and revolutionized our manufacturing processes. Through their expertise and advanced robotic systems, we have been able to achieve exceptional results in terms of productivity, quality, and workforce optimization. As we continue to embrace automation, we are excited about the possibilities that lie ahead and the positive impact it will have on our industry.

Check out the coil packing solution with the leading industrial robot manufacturers for a professional solution right here: Industrial Robot

“Efficient Automation: Witness Robots in Action at a State-of-the-Art Hardening Shop, Revolutionizing Industrial Robotics”