Title: Automatic Packing Line Reviews: Efficient Size 0 Capsule Packaging for Creatine Monohydrate | Pharma Tech Review

Description:

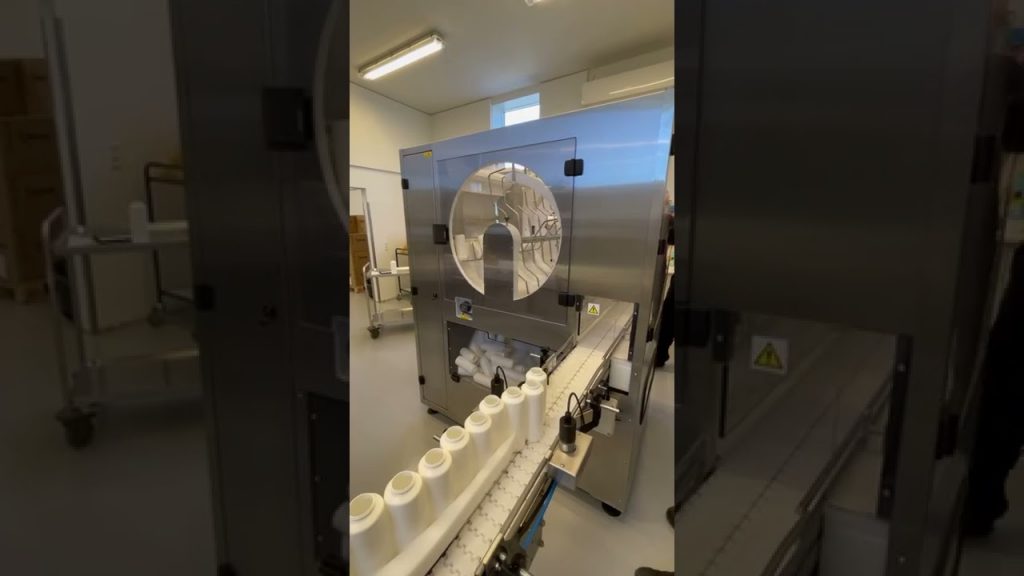

Welcome to Pharma Tech Review, the leading platform for showcasing cutting-edge advancements in pharmaceutical technology. In this video, we delve into the world of automatic packing lines and explore their role in the efficient production of size 0 capsules, specifically focusing on packaging creatine monohydrate. Join us as we uncover the benefits and features of automated production lines, providing a comprehensive review of their capabilities.

With detailed insights and expert analysis, we shed light on the crucial aspects of size 0 capsule packaging, expounding on the significance of this process in the pharmaceutical industry. Discover how these automated production lines streamline the packaging of creatine monohydrate, ensuring precision and efficiency.

Throughout the video, we showcase the operation steps involved in the automatic packing line, offering a step-by-step walkthrough of the process. Highlighting key points and interesting facts, our video content provides a comprehensive understanding of how these production lines contribute to the seamless packaging of size 0 capsules.

To stay updated on the latest advancements in pharmaceutical technology, remember to like, subscribe, and share this video. By doing so, you’ll ensure that you never miss out on our informative content.

Additional Tags and Keywords: automatic packing line, size 0 capsule packaging, creatine monohydrate, pharmaceutical technology, production line, sports nutrition, workout

Hashtags: #productionline #creatine #sportsnutrition #workout

Title: Optimizing Size 0 Capsule Packaging Efficiency: Automated Production Line for Creatine Monohydrate

Introduction:

In the fast-paced pharmaceutical industry, maximizing production efficiency is crucial to meet the growing demand for various supplements. This article presents an innovative solution: an automated production line specifically designed for packaging Size 0 capsules of Creatine Monohydrate. By streamlining the packaging process, this technology aims to enhance productivity, reduce manual labor, and ensure the highest quality and accuracy in capsule packaging.

Streamlining the Packaging Process:

The automated production line for Size 0 Capsule Packaging leverages cutting-edge technology and robotics to optimize efficiency. The system is equipped with various modules that seamlessly integrate to transform the traditional packaging process into an automated and precise operation, minimizing human errors and enhancing overall productivity.

Automated Filling and Weighing:

The automated filling module ensures accurate measurement and dosage of Creatine Monohydrate into each Size 0 capsule. Utilizing advanced sensors and computerized control, the system precisely dispenses the required amount of creatine powder, eliminating the need for manual weighing and reducing the risk of inconsistencies.

Capsule Sorting and Inspection:

To maintain the highest quality standards, the automated production line incorporates a capsule sorting and inspection module. This module utilizes advanced imaging technology to detect any defects, such as empty or misshapen capsules, and promptly removes them from the production line. This process ensures that only the highest quality capsules are used, reducing wastage and enhancing customer satisfaction.

Automated Capping and Sealing:

The capping and sealing module of the production line automates the process of securely closing each capsule, preventing any leakage or contamination. By utilizing precise robotics and advanced sealing techniques, the system ensures airtight encapsulation, maintaining the integrity and potency of the Creatine Monohydrate inside.

Quality Control and Traceability:

To comply with regulatory requirements, the automated production line includes an integrated quality control and traceability system. This system captures real-time data throughout the packaging process, allowing for comprehensive tracking and documentation of every capsule produced. This enables quick identification and resolution of any quality issues, ensuring product safety and regulatory compliance.

Conclusion:

The automated production line for Size 0 Capsule Packaging revolutionizes the packaging process for Creatine Monohydrate supplements. By optimizing efficiency, reducing manual labor, and improving quality control, this technology enhances productivity and ensures the delivery of high-quality products to meet the market’s increasing demands. With its advanced automation and traceability features, this innovative solution is set to transform the pharmaceutical industry’s approach to capsule packaging. coil packing line

#Size #Capsule #Packaging #Automated #Production #Line #Creatine #Monohydrate #Pharma #Tech #Review