Title: “Efficient and Versatile Automatic Box Packing Line: Enhancing Carton Packaging with Weighing, Labeling, Taping, and Strapping”

Description:

Introduction:

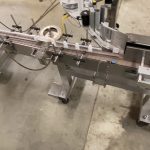

Welcome to our video showcasing the remarkable capabilities of the Automatic Box Packing Line. This advanced system revolutionizes the carton packaging process by incorporating various innovative features such as a Weighing System, Labeler (PLC), Tapping Machine, and Strapping machine. In this video, we will delve into the intricacies of this state-of-the-art packaging line, highlighting its exceptional efficiency and versatility.

Video Content:

– Discover the Components: We will start by providing an in-depth overview of the Automatic Box Packing Line’s key components. From the precise Weighing System, which ensures accurate measurements, to the Labeler (PLC) that seamlessly applies labels with precision, every step of the packaging process is optimized for efficiency.

– Streamlined Taping Process: Witness the Tapping Machine in action as it effortlessly seals cartons, ensuring secure packaging. This machine boasts advanced features that enhance productivity and minimize downtime, guaranteeing a smooth packaging workflow.

– Efficient Strapping Capabilities: Our Strapping machine is designed to tighten and secure cartons swiftly and securely. We will showcase its high-speed strapping capabilities, highlighting its contribution to efficient packaging operations.

Key Highlights and Benefits:

– Versatile Packaging Solutions: The Automatic Box Packing Line caters to a wide range of industries, including e-commerce, logistics, and manufacturing. Its adaptability allows for seamless integration into various packaging environments.

– Enhanced Productivity: By automating essential packaging tasks, this line significantly reduces manual labor and increases productivity. Experience faster packaging cycles and more streamlined operations, ultimately leading to greater output and profitability.

– Improved Accuracy and Quality: The precise weighing system and automated labeling process ensure accurate product measurements and professional-looking packaging. Say goodbye to inconsistencies and errors in your packaging operations.

– Cost-effective Solution: Investing in the Automatic Box Packing Line saves costs in the long run by reducing labor expenses, minimizing packaging material wastage, and optimizing overall operational efficiency.

Call to Action:

If you found this video informative and insightful, we encourage you to like, subscribe, and share it with your colleagues and industry peers. Stay updated with the latest advancements in automatic packaging technology by subscribing to our channel.

Additional Tags and Keywords: automatic box packing line, automatic carton packaging line, weighing system, labeler, PLC, tapping machine, strapping machine, packaging automation, efficient carton packaging, automated packaging solutions.

Hashtags: #AutomaticBoxPacking #CartonPackagingLine #WeighingSystem #Labeler #TappingMachine #StrappingMachine #PackagingAutomation

Sure! Here’s a sample tilter for an Automatic Carton Packaging Line:

Title: Automatic Carton Packaging Line Tilter

Objective:

To design and implement a tilter system for an automatic carton packaging line that efficiently rotates and positions cartons for packaging.

Requirements:

1. Rotation Capability: The tilter should be able to rotate cartons to a desired angle (e.g., 90 degrees) for proper orientation during packaging.

2. Speed and Efficiency: The tilter should operate at a fast and consistent speed to ensure smooth carton rotation without compromising the packaging line’s overall productivity.

3. Adjustable Parameters: The tilter should allow operators to adjust rotation speed, angle, and other parameters to accommodate different carton sizes and packaging requirements.

4. Safety Measures: The tilter should incorporate safety features, such as emergency stop buttons, safety guards, and sensors to prevent accidents and protect operators.

5. Integration: The tilter should seamlessly integrate with the existing automatic carton packaging line without causing disruptions or delays in the overall packaging process.

6. Durability and Reliability: The tilter should be built with high-quality materials and components to ensure long-term durability and reliable performance in a demanding production environment.

7. Maintenance and Serviceability: The tilter should be designed for easy maintenance, with accessible components and clear instructions for troubleshooting and repairs.

Implementation:

1. Design a mechanical system that can securely hold and rotate cartons. Consider using conveyor belts, grippers, or pneumatic systems for rotation.

2. Incorporate a control system that allows operators to adjust rotation speed, angle, and other parameters as required.

3. Install safety features like emergency stop buttons, safety guards, and sensors to ensure operator safety during operation.

4. Integrate the tilter with the existing automatic carton packaging line, ensuring proper synchronization and minimal disruption to the overall process.

5. Test the tilter system with different carton sizes and weights to ensure its efficiency and effectiveness in rotating and positioning cartons accurately.

6. Provide clear instructions and training for operators on how to use and maintain the tilter system.

7. Regularly inspect and maintain the tilter system to prevent any malfunctions or breakdowns, and promptly address any issues that arise.

By following this tilter design and implementation plan, the automatic carton packaging line will benefit from improved carton rotation and positioning, leading to increased productivity and efficiency in the packaging process. coil packing line

#Automatic #Carton #Packaging #Line