Check out the leading manufacturer for professional coil packing solutions here:

—

Title: Enhancing Efficiency and Precision with Industrial Automation Robots in the Ball Bearing Assembly Process

Introduction:

In the fast-paced world of manufacturing, precision and efficiency are vital for success. Industrial automation robots have revolutionized various assembly processes, including ball bearing assembly. In this article, we will explore the use of the FANUC M-1iA robot in the ball bearing assembly process, highlighting its benefits and contributions to the industry.

—

Opinion/Thought Piece Style:

The Role of Industrial Automation Robots in Ball Bearing Assembly

Industrial automation robots have transformed the manufacturing landscape, streamlining processes and increasing productivity. The ball bearing assembly process is no exception, and the FANUC M-1iA robot has emerged as a game-changer in this field.

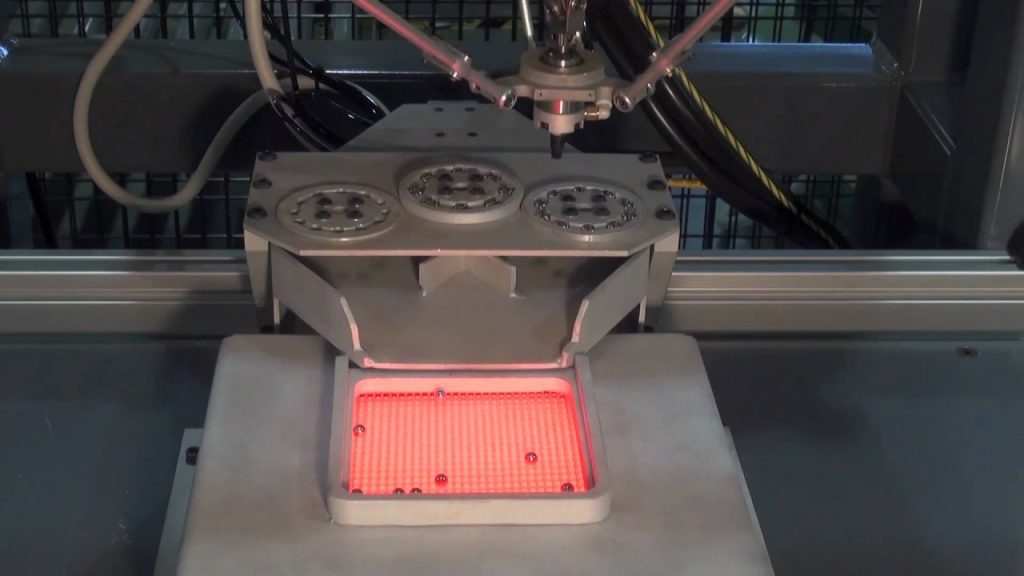

The FANUC M-1iA robot is specifically designed for high-speed and precise assembly tasks. With its advanced vision system, it can locate and handle three different size ball bearings with ease. This capability ensures accurate placement and reduces the risk of errors, improving overall product quality.

Moreover, the M-1iA robot’s compact design allows for easy integration into existing assembly lines. Its small footprint optimizes floor space utilization, making it an ideal choice for manufacturers looking to maximize efficiency.

—

Explanatory Style:

Understanding the Ball Bearing Assembly Process with the FANUC M-1iA Robot

The ball bearing assembly process requires utmost precision to ensure the smooth operation of various machinery and equipment. The FANUC M-1iA robot plays a crucial role in automating this process, offering numerous advantages over traditional manual assembly methods.

Equipped with advanced vision technology, the M-1iA robot can accurately locate and handle three different size ball bearings. This capability eliminates the risk of human error and guarantees consistent and precise placement. By reducing the chances of misalignment or faulty assembly, manufacturers can enhance product quality and reliability.

Additionally, the M-1iA robot’s high-speed capabilities enable faster assembly cycles, leading to increased productivity and shorter production times. Its compact design allows for seamless integration into existing assembly lines, minimizing disruption and optimizing overall efficiency.

—

How-to Guide Style:

Streamlining Ball Bearing Assembly with the FANUC M-1iA Robot: A Step-by-Step Guide

Step 1: Preparation

– Set up the FANUC M-1iA robot in a suitable work area, ensuring proper safety measures are in place.

– Connect the robot to the assembly line and power source.

Step 2: Programming

– Utilize the FANUC programming software to create a customized program for the ball bearing assembly process.

– Define the robot’s movements, including locating and handling the different size ball bearings.

Step 3: Calibration

– Calibrate the robot’s vision system to accurately identify and locate the ball bearings.

– Fine-tune the robot’s gripping mechanism for optimal handling.

Step 4: Integration

– Integrate the M-1iA robot into the existing assembly line, ensuring smooth coordination with other machinery and equipment.

– Test the robot’s functionality and adjust any parameters if necessary.

Step 5: Operation

– Initiate the ball bearing assembly process using the programmed instructions.

– Monitor the robot’s performance and address any issues promptly.

By following these steps, manufacturers can streamline the ball bearing assembly process, leveraging the precision and efficiency of the FANUC M-1iA robot.

—

Conclusion:

The use of industrial automation robots, such as the FANUC M-1iA, has revolutionized the ball bearing assembly process. Through its advanced vision system, high-speed capabilities, and compact design, the M-1iA robot offers unparalleled precision, efficiency, and quality in this critical manufacturing task. Embracing the power of industrial automation robots is key to staying competitive in the ever-evolving manufacturing industry.

—

Check the coil packing solution with the leading manufacturer for professional solutions here. Industrial Robot

“Efficient Assembly Robot for Ball Bearings – Enhancing Industrial Automation Efficiency”