If you are in the market for a Semi-Automatic Plastic Injection Machine, then you have come to the right place. In this article, we will be discussing the features and benefits of this cutting-edge machine, as well as exploring its applications and the advantages it offers over traditional molding techniques. So, let’s dive in!

Introduction

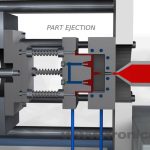

The Semi-Automatic Plastic Injection Machine is a revolutionary piece of equipment that combines the efficiency of automation with the precision of injection molding. This machine is designed to streamline the plastic injection process, making it faster, more accurate, and more cost-effective. With its advanced features and user-friendly interface, it has become a game-changer in the manufacturing industry.

Features and Benefits

The Semi-Automatic Plastic Injection Machine comes packed with a range of features that set it apart from its competitors. Here are some of its key benefits:

1. High Efficiency: This machine is equipped with state-of-the-art technology that ensures maximum productivity. It can produce a large number of plastic parts in a short period, reducing production time and costs.

2. Precision and Accuracy: The Semi-Automatic Plastic Injection Machine offers unparalleled precision and accuracy in the molding process. It ensures consistent quality and minimizes the risk of defects, resulting in higher customer satisfaction.

3. Easy Operation: Designed with user-friendliness in mind, this machine can be easily operated by anyone with minimal training. Its intuitive interface and clear instructions make it accessible to both experienced operators and beginners.

Applications

The Semi-Automatic Plastic Injection Machine finds its applications in a wide range of industries. Here are a few examples:

1. Automotive Industry: This machine is widely used in the automotive industry for manufacturing various plastic components, such as dashboards, bumpers, and interior trims.

2. Consumer Goods: It is also utilized in the production of consumer goods like toys, household appliances, and electronic devices. Its high efficiency and accuracy make it ideal for mass production.

3. Medical Industry: The Semi-Automatic Plastic Injection Machine plays a crucial role in the production of medical devices and equipment. Its precision ensures the reliability and safety of these critical components.

Advantages over Traditional Molding Techniques

Compared to traditional molding techniques, the Semi-Automatic Plastic Injection Machine offers several advantages:

1. Cost Savings: This machine significantly reduces production costs by minimizing material waste and labor requirements. Its efficiency allows for faster production cycles, resulting in higher output and lower overall costs.

2. Improved Quality Control: The advanced technology of this machine ensures consistent quality and reduces the risk of defects. This leads to better quality control and fewer rejected parts, saving time and resources.

3. Flexibility and Versatility: The Semi-Automatic Plastic Injection Machine can handle a wide range of plastic materials and designs, providing manufacturers with greater flexibility and versatility in their production processes.

Conclusion

The Semi-Automatic Plastic Injection Machine is a game-changer in the manufacturing industry. With its high efficiency, precision, and user-friendly interface, it offers numerous benefits over traditional molding techniques. Whether you are in the automotive, consumer goods, or medical industry, this machine can revolutionize your production process and help you stay ahead of the competition.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert appropriate call-to-action] Plastic Injection Machine

“Efficient Air-Controlled Hand Molding Machine & Semi-Automatic Plastic Injection System: Streamlining Manufacturing Processes”