Title: Ultimate Guide to Industrial Food Packing Machine and Vacuum Packing Machine with 6-side Brick Shape Bag 5kg Rice Packaging Spot

Description:

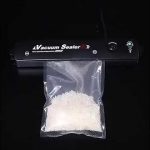

Welcome to our comprehensive guide on Industrial Food Packing Machine and Vacuum Packing Machine with 6-side Brick Shape Bag 5kg Rice Packaging Spot! In this video, we provide an in-depth overview and demonstration of these cutting-edge machines, showcasing their remarkable features and functionality.

Introduction:

In this video, we delve into the world of Industrial Food Packing Machine and Vacuum Packing Machine with 6-side Brick Shape Bag 5kg Rice Packaging Spot. Whether you are a food manufacturer, distributor, or simply curious about the latest packaging technology, this video will provide valuable insights and information to enhance your understanding.

Video Content:

1. Overview of Industrial Food Packing Machine:

– Introduction to the machine’s purpose and benefits

– Explanation of its advanced features and capabilities

– Importance of efficient and precise packaging in the food industry

2. Overview of Vacuum Packing Machine with 6-side Brick Shape Bag 5kg Rice Packaging Spot:

– Detailed explanation of the machine’s unique design and functionality

– Benefits of vacuum packaging for preserving food freshness and extending shelf life

– Demonstration of the machine in operation, showcasing its efficiency and reliability

3. Key Highlights and Interesting Facts:

– Explore the various types of packaging materials that can be used with these machines

– Discover the wide range of applications in the food industry, including packaging rice, grains, and other products

– Learn about the customization options available to suit different packaging needs

Operation Steps:

1. Step 1: Preparation and setup of the Industrial Food Packing Machine

2. Step 2: Loading the 6-side Brick Shape Bag with 5kg of rice

3. Step 3: Operating the Vacuum Packing Machine for airtight packaging

4. Step 4: Quality control and inspection of the packaged rice

5. Step 5: End of the packaging process and machine maintenance tips

Call to Action:

If you found this video informative and useful, please consider liking, subscribing, and sharing it with others who might benefit from this valuable content. Stay tuned for more videos on industrial packaging solutions.

Additional Tags and Keywords:

Industrial Food Packing Machine, Vacuum Packing Machine, Brick Shape Bag, 5kg Rice Packaging, Packaging Spot, Vacuum Packing, Food Packaging, Rice Packaging Machine, Packaging Technology, Packaging Solutions, Food Industry, Packaging Efficiency

Hashtags:

#IndustrialFoodPacking #VacuumPackingMachine #BrickShapeBag #RicePackaging #PackagingSpot #FoodIndustry #PackagingSolutions #PackagingTechnology

Here is a tilter program for a Vacuum Packing Machine with a 6 side brick shape bag for 5kg rice packaging spot:

1. Start the Vacuum Packing Machine.

2. Initialize the tilter mechanism to its default position.

3. Place the empty 6 side brick shape bag on the tilter platform.

4. Activate the tilter to tilt the bag at a specific angle (e.g., 45 degrees).

5. Start filling the bag with 5kg of rice.

6. Once the bag is filled, deactivate the tilter and bring it back to its default position.

7. Activate the vacuum sealing process to remove excess air from the bag.

8. Seal the bag securely to maintain the vacuum.

9. Disengage the tilter mechanism and return it to its default position.

10. Remove the vacuum-sealed bag from the tilter platform.

11. Repeat the process for the next bag.

Note: The specific implementation details may vary depending on the vacuum packing machine’s design and control system.Food Packing Machine

#Vacuum #Packing #Machine #side #Brick #Shape #Bag #5kg #Rice #Packaging #Spot