Check the Industrial Robot Arm welding, loading and unloading, stamping, and pick and place video to see how our factory utilizes advanced technology to improve manufacturing efficiency. In this article, we will dive into the details of our video, highlighting the benefits of using an Industrial Robot Arm and providing an in-depth analysis of its functionalities.

Title: Enhancing Manufacturing Efficiency with Industrial Robot Arm: A Comprehensive Video Guide

Introduction:

Welcome to our video showcasing the plate welding process using an Industrial Robot Arm. As a leading manufacturer of robots for various industrial applications, our factory specializes in developing advanced solutions for welding, loading and unloading, stamping, and pick and place operations. In this article, we will take you through the video, providing valuable insights into the capabilities of our Industrial Robot Arm and the benefits it brings to the manufacturing industry.

Section 1: Industrial Robot Arm – Revolutionizing Manufacturing Processes

In this section, we will discuss the significance of Industrial Robot Arms in transforming traditional manufacturing processes. With their exceptional precision, speed, and flexibility, these robotic arms have become indispensable assets for various industries. They have revolutionized the way welding, loading and unloading, stamping, and pick and place operations are carried out, resulting in improved efficiency and productivity.

Section 2: Exploring the Plate Welding Process

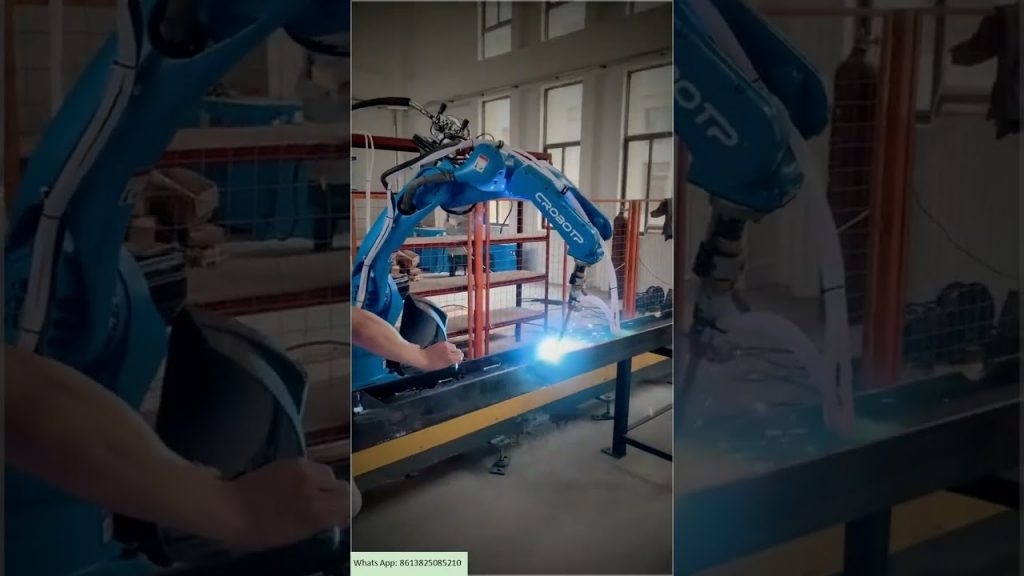

In this section, we will guide you through the plate welding process showcased in the video. Our Industrial Robot Arm demonstrates its exceptional welding capabilities, ensuring precise and consistent welds on plates. The video highlights the ease of programming, enabling the robot arm to adapt to different plate sizes and shapes effortlessly. With its 6-axis design, the Industrial Robot Arm offers enhanced maneuverability, allowing it to reach even the most challenging welding positions.

Section 3: Advantages of Using an Industrial Robot Arm

In this section, we will analyze the benefits of utilizing an Industrial Robot Arm in manufacturing processes. The video showcases how our robot arm improves efficiency by reducing human error and increasing production speed. With its high repeatability, the Industrial Robot Arm ensures consistent and accurate results, minimizing the need for rework. Furthermore, its ability to handle complex tasks, such as loading and unloading heavy materials or stamping operations, further enhances productivity and worker safety.

Section 4: Future Implications and Predictive Analysis

In this section, we will delve into the future implications of Industrial Robot Arms in the manufacturing industry. We will discuss the potential advancements in technology, such as incorporating artificial intelligence and machine learning algorithms, which will further enhance the capabilities of these robotic arms. Additionally, we will provide a predictive analysis of how Industrial Robot Arms will continue to shape the future of manufacturing, offering increased automation and improved operational efficiency.

Conclusion:

The Industrial Robot Arm showcased in our video highlights the immense potential it holds for transforming various manufacturing processes. With its versatility, precision, and speed, it offers a wide range of applications, including plate welding, loading and unloading, stamping, and pick and place operations. By implementing an Industrial Robot Arm, manufacturers can significantly improve efficiency, productivity, and product quality.

Check the coil packing solution with a leading manufacturer for professional solutions in the industry. With their expertise and advanced technology, they can provide tailored solutions for all your packaging needs. Industrial Robot

“Efficient Welding and Stamping with a Versatile 6-Axis Industrial Robot Arm”