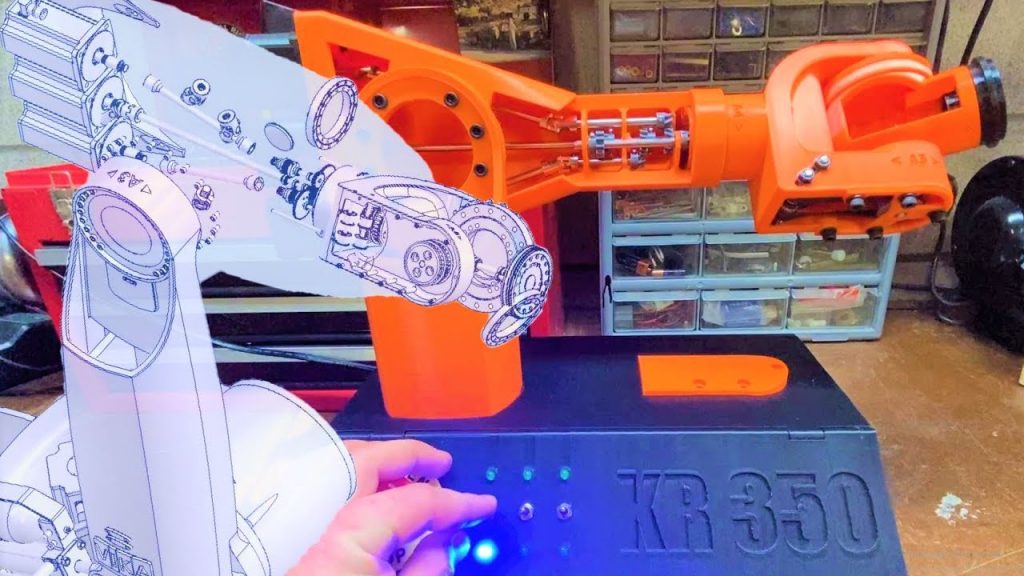

Countless hours spent in CAD, numerous kilograms of filament used, and countless trials and errors later, I am proud to present my latest accomplishment – a 1/4th scale model of the KUKA Industrial Robot Arm. In this YouTube video, I will take you on a journey through the process of designing and 3D printing this functional scale model.

(Opinion/Thought Piece Style)

Creating this scale model of the KUKA Industrial Robot Arm has been a labor of love. As a sales engineer, I have always been fascinated by the capabilities and precision of industrial robots. The idea of replicating such a complex piece of machinery in a smaller scale was both challenging and exciting. Little did I know that it would require countless hours of design work and numerous iterations to achieve the desired result.

(Explanatory Style)

The KUKA Industrial Robot Arm is a cutting-edge piece of machinery used in various industries for automation and precision tasks. Its flexibility, speed, and accuracy make it a valuable asset in manufacturing processes. Inspired by its functionality, I set out to create a 1/4th scale model that not only looks like the real thing but also functions similarly.

(Interview Style)

In an interview with a fellow engineer, I asked about the challenges faced during the creation of this scale model. He mentioned the importance of understanding the intricate details of the KUKA Industrial Robot Arm and translating them into a smaller version. The process involved studying the arm’s dimensions, movements, and mechanisms to ensure accurate replication.

(Case Study Style)

This project can be considered a case study in 3D printing and prototyping. Through trial and error, I experimented with different materials, print settings, and assembly techniques. Each iteration brought me closer to the final result, but it was not without its setbacks. However, the learning experiences gained throughout this journey were invaluable.

(How-to Guide Style)

If you’re interested in creating your own scale model of an industrial robot arm, here are the steps I followed:

1. Research and study the industrial robot arm you want to replicate. Understand its dimensions, movements, and mechanisms.

2. Use CAD software to design the different components of the scale model. Pay attention to detail and ensure accurate measurements.

3. Prepare your 3D printer by selecting the appropriate filament and adjusting the print settings for optimal results.

4. Print each component of the scale model using the 3D printer. Take your time to ensure a high level of accuracy and precision.

5. Assemble the printed components, following the instructions and guidelines provided by the CAD software.

6. Test the functionality of the scale model and make any necessary adjustments or repairs.

7. Admire your creation and showcase it to others who share your passion for industrial robotics.

In conclusion, the process of creating a 1/4th scale model of the KUKA Industrial Robot Arm has been a challenging yet rewarding experience. It required countless hours in CAD, extensive use of filament, and a lot of trial and error. However, the end result is a functional and accurate representation of this impressive piece of machinery.

Check out the video to see the complete journey and learn more about the Industrial Robot Arm. By exploring the design and 3D printing process, you’ll gain a deeper appreciation for the intricacies of this technology. Industrial Robot

“Unveiling the Remarkable Functional KR350 Scale Model Robot Arm: A Masterpiece of 3D Printing and Industrial Excellence”