Are you in search of the best plastic injection machine? Look no further! In this article, we will explore the top-notch plastic injection machines available in the market and discuss their features and benefits. We will also delve into the production of 20L Jerrycan blow molding machines with a down blow pin system. So, let’s dive in and discover the world of plastic injection machines!

Plastic injection machines are widely used in various industries for manufacturing plastic products. These machines play a crucial role in the production process by injecting molten plastic into molds, resulting in the formation of different shapes and sizes. The quality of the injection machine determines the accuracy, efficiency, and reliability of the final product.

When it comes to the best plastic injection machines, there are several key factors to consider. These include precision, speed, durability, and versatility. The machine should be able to deliver precise and consistent results, operate at high speeds to meet production demands, withstand rigorous use without compromising performance, and offer flexibility to accommodate various plastic materials and designs.

One of the leading manufacturers of plastic injection machines is known for its commitment to excellence and innovation. Their machines are equipped with advanced technology and features that ensure optimal performance and productivity. From small-scale production to large-scale manufacturing, their range of machines caters to diverse needs.

Continuous extrusion is another crucial aspect of plastic manufacturing. It is a process that involves the continuous production of plastic products by extruding the molten plastic through a die. This method offers several advantages, including cost-effectiveness, high production rates, and consistency in product quality. By integrating continuous extrusion technology with plastic injection machines, manufacturers can enhance their production capabilities and achieve superior results.

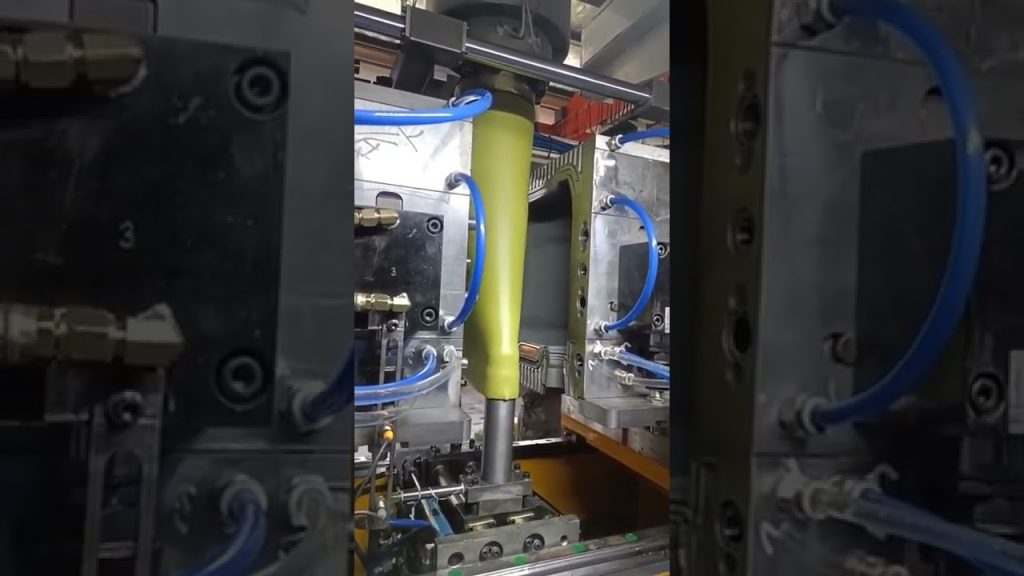

In the case of 20L Jerrycan blow molding machines with a down blow pin system, the production process involves injecting plastic into a mold and then blowing air into the mold to expand the plastic and create the desired shape. The down blow pin system ensures uniform distribution of plastic and enables efficient production of high-quality Jerrycans. This technology not only improves productivity but also reduces wastage and enhances the overall manufacturing process.

Now, let’s take a closer look at the benefits of using the best plastic injection machines. Firstly, these machines offer exceptional precision, ensuring that each product meets the required specifications. Secondly, they are designed to operate at high speeds, enabling manufacturers to meet tight production deadlines and maximize efficiency. Thirdly, the durability of these machines ensures long-term reliability and minimal downtime, resulting in increased productivity and profitability.

In addition to the above benefits, the best plastic injection machines also provide versatility. They can accommodate a wide range of plastic materials and designs, allowing manufacturers to cater to different customer demands. This flexibility is essential in today’s dynamic market, where customization and personalization are key factors driving consumer choices.

To sum it up, investing in the best plastic injection machine is crucial for any company involved in plastic manufacturing. These machines offer precision, speed, durability, and versatility, ensuring optimal performance and productivity. By integrating continuous extrusion and down blow pin system technologies, manufacturers can further enhance their production capabilities and achieve superior results.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Plastic Injection Machine

“Enhancing Efficiency: Continuous Extrusion for 20L Jerrycan Blow Molding Machine with Down Blow Pin System & Top-notch Plastic Injection Machine”