Check out our leading manufacturer for professional coil packing solutions here:

Title: Testing the Efficiency of a 12-Cavity Urine Cup Mould Using an Injection Molding Machine

Introduction:

In the world of plastic injection molding, precision and efficiency are key factors that determine the success of a manufacturing process. One important aspect of this process is the testing of molds, which ensures the quality and functionality of the final product. In this YouTube video, we will explore the testing of a 12-cavity urine cup mold using an injection molding machine. Join us as we dive into the intricacies of this process and witness the power of a plastic injection molding machine in action.

[Video Introduction]

1. Explanatory Style:

In this video, we aim to provide a comprehensive explanation of the testing process for a 12-cavity urine cup mold using an injection molding machine. We will cover the following key aspects:

– Understanding the role of injection molding machines in the manufacturing process.

– Analyzing the significance of mold testing for ensuring quality and functionality.

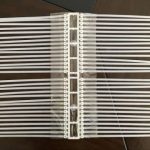

– Demonstrating the efficiency and precision of a 12-cavity urine cup mold.

– Exploring the various steps involved in the testing process.

– Highlighting the benefits of using a plastic injection molding machine.

2. In-depth Analysis Style:

To delve deeper into the topic, let’s analyze the testing process for a 12-cavity urine cup mold using an injection molding machine. This analysis will allow us to gain a better understanding of the intricacies involved in achieving optimal results.

– Step 1: Mold Preparation: Before the testing process begins, the mold needs to be properly prepared. This includes ensuring the cleanliness of the mold, checking for any defects, and making necessary adjustments.

– Step 2: Injection Molding Machine Setup: The injection molding machine is set up according to the desired specifications. This involves configuring the temperature, pressure, and speed settings to achieve the desired outcome.

– Step 3: Material Injection: Once the machine is set up, the molten plastic material is injected into the mold cavity. The injection process must be precise to avoid any defects or inconsistencies in the final product.

– Step 4: Cooling and Ejection: After the material is injected, the mold is cooled to solidify the plastic. Once cooled, the mold opens, and the newly formed urine cups are ejected.

– Step 5: Quality Control: The urine cups are carefully inspected for any defects, such as air bubbles, uneven surfaces, or incorrect dimensions. This step ensures that only high-quality cups are approved for further use.

3. Predictive/Foresight Style:

Looking ahead, the future of plastic injection molding machines and mold testing seems promising. Advancements in technology have paved the way for more efficient and accurate testing methods. With the integration of artificial intelligence and robotics, the testing process will become even more streamlined, reducing the chances of human error and maximizing productivity.

Conclusion:

In this YouTube video, we explored the testing process for a 12-cavity urine cup mold using an injection molding machine. We witnessed the precision and efficiency of the machine in producing high-quality urine cups. Plastic injection molding machines play a vital role in the manufacturing industry, ensuring the production of consistent and reliable products. As technology continues to evolve, we can expect even greater advancements in the field of mold testing and injection molding.

Check out our leading manufacturer for professional coil packing solutions here. Plastic Injection Machine

Testing the 12-Cavity Urine Cup Mould with an Injection Molding Machine