Title: Advanced Semi-Automatic Food Packing Machine for Efficient Grocery Packaging | Masala Packing Machine 10-1kg gm

Description:

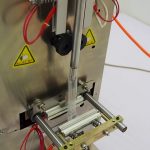

Welcome to our informative video highlighting the exceptional features and capabilities of our advanced Semi-Automatic Food Packing Machine. This state-of-the-art packaging solution is designed to revolutionize the grocery packaging industry, ensuring efficient and precise packing of various items, including Masala (10-1kg gm) and other grocery products.

In this video, we showcase the outstanding performance and versatility of our Semi-Automatic Food Packing Machine. With its user-friendly interface and cutting-edge technology, this machine offers seamless operation and remarkable accuracy. Whether you’re packaging Masala or other grocery items, our machine guarantees consistent results, minimizing wastage and maximizing productivity.

Key Features:

1. Efficient Pouch Packing: Our Semi-Automatic Food Packing Machine enables quick and hassle-free packing of grocery items, ensuring optimal efficiency and reduced labor costs.

2. Versatile Packaging Options: With its customizable settings, this machine accommodates various pouch sizes and packaging requirements, offering flexibility for different product categories.

3. Precise Weight Measurement: The machine’s advanced weighing system ensures accurate measurement of Masala and other grocery items, maintaining consistency and quality.

4. User-Friendly Interface: Equipped with intuitive controls and a user-friendly interface, our machine simplifies the packaging process, making it accessible even for operators with minimal training.

5. Robust and Durable: Built with high-quality materials, our Semi-Automatic Food Packing Machine is designed to withstand demanding production environments, ensuring long-lasting performance.

Watch this video to witness the seamless operation of our Semi-Automatic Food Packing Machine and discover how it can optimize your grocery packaging process. Don’t forget to like, subscribe, and share this video with others who can benefit from our innovative packaging solution.

Additional Tags: semi auto pouch packing machine, grocery items packing machine, masala packaging, advanced food packaging, efficient grocery packing, automatic pouch packing, extreme packaging, food packaging technology

Hashtags: #FoodPackingMachine #GroceryPackaging #MasalaPacking #ExtremePackaging #EfficientPouchPacking

Here is a possible tilter for a semi-automatic pouch packing machine for masala and grocery items:

Title: Semi-Automatic Pouch Packing Machine Tilter for Masala and Grocery Items

Introduction:

The tilter for a semi-automatic pouch packing machine is an essential component in the packaging process of masala and grocery items. This tilter ensures that the products are accurately filled and sealed into pouches, providing convenience and efficiency in the packaging industry. This article aims to provide an overview of the tilter’s functionality and its benefits in the packaging process.

1. Functionality of the Tilter:

The tilter in a semi-automatic pouch packing machine is responsible for positioning the pouches in an upright position before the filling process. It uses mechanical mechanisms to rotate the pouches and ensure they are correctly aligned for the subsequent filling and sealing operations. This precise positioning guarantees accurate product measurement and minimizes wastage, enhancing the overall packaging efficiency.

2. Features and Specifications:

a. Rotation Mechanism: The tilter is equipped with a robust rotation mechanism that smoothly rotates the pouches, maintaining their stability throughout the process.

b. Adjustable Speed: The tilter offers adjustable speed settings to accommodate various product sizes and packaging requirements, ensuring flexibility and versatility.

c. Easy Operation: The tilter is designed with user-friendly controls and interfaces, allowing operators to effortlessly adjust the settings and monitor the process.

d. Durability: Constructed with high-quality materials, the tilter is built to withstand heavy usage and provide long-lasting performance in demanding production environments.

3. Benefits of the Tilter:

a. Improved Efficiency: By accurately positioning the pouches, the tilter reduces the chances of misalignment during the filling and sealing process. This, in turn, minimizes production errors, enhances efficiency, and increases the packaging output.

b. Cost Reduction: The precise filling and reduced wastage achieved by the tilter contribute to cost reduction in terms of raw materials and labor.

c. Enhanced Product Quality: The tilter ensures that the products are consistently filled in the pouches, maintaining their integrity and quality throughout the packaging process. This improves customer satisfaction and brand reputation.

d. Time-saving: The tilter’s automated rotation mechanism saves time by eliminating the need for manual pouch positioning, enabling faster packaging operations and higher productivity.

Conclusion:

The tilter for a semi-automatic pouch packing machine plays a crucial role in the packaging of masala and grocery items. Its functionality, features, and benefits contribute to improved efficiency, cost reduction, enhanced product quality, and time-saving. Investing in a reliable tilter ensures smooth packaging operations and facilitates the delivery of high-quality products to customers in the food and grocery industry.Food Packing Machine

#Semi #Auto #Pouch #Packing #Machine #Masala #Packing #Machine #101kg #Grocery #Items #Packing #Machine