Check out our website for the best industrial robot price and selection criteria for industrial robots. We have conducted a comprehensive review of the most important factors to consider when choosing an industrial robot.

Industrial robots play a crucial role in modern manufacturing processes. They automate tasks that are repetitive, dangerous, or require high precision. As a sales engineer, I understand the importance of finding the right industrial robot for your specific needs and budget.

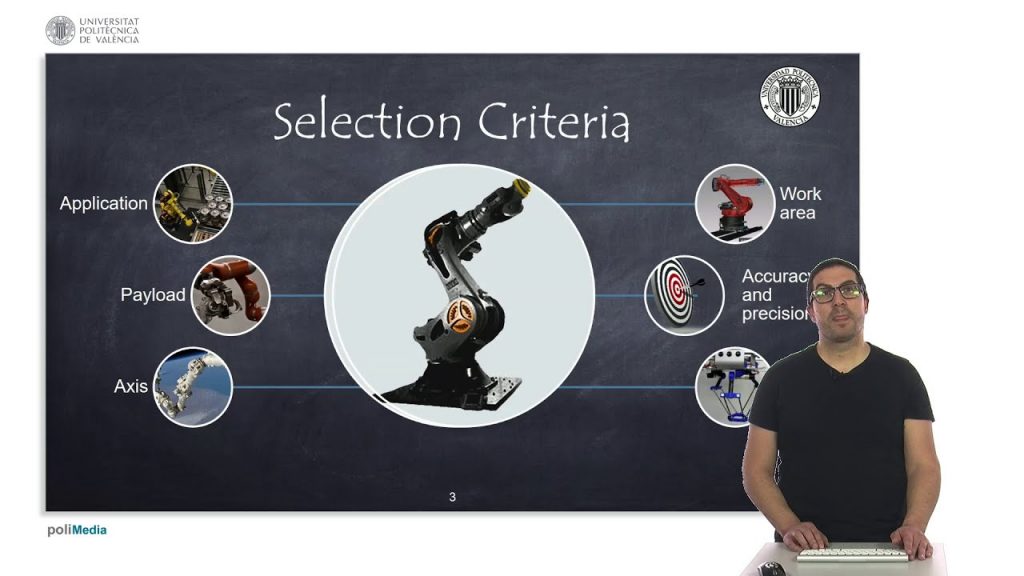

When it comes to selecting an industrial robot, there are several key criteria to consider. Let’s dive into each of these criteria to help you make an informed decision.

1. Payload Capacity: The payload capacity refers to the maximum weight that a robot can handle. It is important to choose a robot that can handle the weight of your products or materials. Oversizing or undersizing the robot can lead to inefficiencies and potential safety risks.

2. Reach: The reach of a robot determines its ability to access different areas within a workspace. Consider the dimensions of your workspace and the range of motion required for your applications. A robot with a longer reach may be more suitable for larger work areas or tasks that require a wide range of movements.

3. Accuracy: Precision is crucial in many industrial processes. The accuracy of a robot is determined by factors such as repeatability and positioning. Make sure to evaluate the robot’s accuracy specifications to ensure it meets your requirements.

4. Speed: The speed of a robot affects the overall productivity of your operations. Depending on your specific application, you may need a robot that can perform tasks quickly and efficiently. Consider the robot’s cycle time and maximum speed capabilities when comparing options.

5. Flexibility: Industrial robots should be adaptable to changing production needs. Look for features such as easy programming, compatibility with different end effectors, and the ability to handle various tasks. A flexible robot can help you optimize your workflow and adapt to future requirements.

6. Cost: Of course, cost is a significant factor in any purchasing decision. Industrial robot prices can vary greatly depending on factors such as brand, features, and capabilities. It’s important to find a balance between your budget and the robot’s performance. Consider the long-term benefits and potential return on investment when evaluating the cost.

By considering these selection criteria, you can narrow down your choices and find the perfect industrial robot for your business.

In conclusion, selecting the right industrial robot requires careful evaluation of various factors such as payload capacity, reach, accuracy, speed, flexibility, and cost. Each of these criteria plays a crucial role in determining the overall performance and suitability of a robot for your specific needs.

If you’re ready to explore the best industrial robot price and selection criteria, visit our website today. We offer a wide range of options that meet the highest industry standards. Our team of experts is here to assist you in finding the perfect solution for your business.

Check out our website now for the best industrial robot price and selection criteria. Don’t miss out on the opportunity to enhance your manufacturing processes with cutting-edge robotics technology. Industrial Robot

“Optimizing Industrial Efficiency: Understanding Selection Criteria and Pricing of Robotic Systems for Enhanced Operations”