Are you tired of manually handling heavy materials in your manufacturing process? Do you want to improve efficiency and reduce the risk of workplace injuries? Look no further than the Semi-Automatic Handling Machine. In this article, we will explore the features and benefits of this innovative machine, as well as provide a step-by-step guide on how to use a semi-automatic handling machine effectively.

Introduction to Semi-Automatic Handling Machine

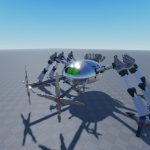

The Semi-Automatic Handling Machine is a game-changer in the manufacturing industry. It is designed to assist workers in handling and moving heavy materials with ease. This machine utilizes advanced technology and automation to streamline the handling process, saving time and effort for workers.

Features and Benefits

1. Increased Efficiency: The Semi-Automatic Handling Machine is designed to improve productivity and efficiency in your manufacturing process. With its automated features, it can handle heavy materials quickly and accurately, reducing the time required for manual handling.

2. Reduced Risk of Injuries: Manual handling of heavy materials can put workers at risk of musculoskeletal injuries. The Semi-Automatic Handling Machine eliminates this risk by taking over the heavy lifting, ensuring the safety of your workforce.

3. Versatility: This machine is suitable for handling a wide range of materials, including coils, sheets, and other heavy objects. Its adjustable features allow it to accommodate various sizes and shapes, making it a versatile solution for different manufacturing needs.

4. Easy to Use: Despite its advanced features, the Semi-Automatic Handling Machine is user-friendly and requires minimal training. Its intuitive interface and ergonomic design make it easy for operators to control and operate the machine effectively.

How to Use a Semi-Automatic Handling Machine

Step 1: Preparation

Before using the machine, ensure that the area is clear of any obstacles and that the machine is in good working condition. Inspect the machine for any damages or abnormalities.

Step 2: Load the Material

Carefully place the material to be handled onto the machine. Ensure that it is secure and balanced to prevent any accidents or damage.

Step 3: Adjust the Settings

Depending on the size and weight of the material, adjust the settings of the Semi-Automatic Handling Machine accordingly. This may include adjusting the lifting capacity, speed, and other parameters.

Step 4: Activate the Machine

Once the material is properly loaded and the settings are adjusted, activate the machine to begin the handling process. Monitor the machine closely to ensure that it is functioning correctly.

Step 5: Unload the Material

After the handling process is complete, carefully unload the material from the machine. Follow proper safety procedures to prevent injuries or damage to the material.

Conclusion

The Semi-Automatic Handling Machine is an essential tool for any manufacturing process that involves heavy materials. Its advanced features and user-friendly design make it a valuable asset in improving efficiency and reducing workplace injuries. By following the step-by-step guide provided in this article, you can effectively use a semi-automatic handling machine and reap its benefits in your manufacturing operations.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert Call-to-Action] Handling Machine

“Efficient Techniques for Operating Semi-Automatic Soldering and Handling Machines: A Comprehensive Guide”