Are you in the market for a plastic injection machine and looking for reliable reviews to help you make an informed decision? Look no further! In this article, we will provide you with a comprehensive review of plastic injection machines, along with insights into injection mold testing and injection molding machines. Whether you’re a professional in the industry or a hobbyist looking to expand your expertise, this article is for you.

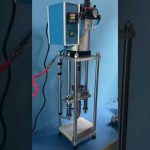

Plastic injection machines have revolutionized the manufacturing industry by enabling the production of complex and intricate plastic parts. These machines use a process called injection molding, where molten plastic is injected into a mold to create a desired shape. With the advancement of technology, these machines have become more efficient, precise, and user-friendly.

To give you an in-depth understanding of plastic injection machines, we will explore various aspects such as their features, benefits, drawbacks, and market trends. By the end of this article, you’ll have a solid foundation to make an informed decision when choosing a plastic injection machine.

Features of Plastic Injection Machines:

– High precision: Modern plastic injection machines offer exceptional precision, allowing for the production of intricate and complex parts with tight tolerances.

– Versatility: These machines can accommodate a wide range of plastic materials, including thermoplastics, thermosetting plastics, and elastomers.

– Automation: Many plastic injection machines come with advanced automation features, such as robotic arms for part handling, which streamline the manufacturing process and increase productivity.

– Energy efficiency: With the increasing focus on sustainability, many manufacturers have developed energy-efficient plastic injection machines, reducing energy consumption and environmental impact.

Benefits of Plastic Injection Machines:

– Cost-effective: Injection molding is a cost-effective manufacturing process, especially for large-scale production. The ability to produce multiple parts simultaneously reduces labor costs and increases efficiency.

– Consistency: Plastic injection machines offer consistent and repeatable results, ensuring the quality and uniformity of the produced parts.

– Design flexibility: Injection molding allows for the production of complex shapes and intricate details that are difficult to achieve with other manufacturing processes.

– Fast production: Once the mold is set up, plastic injection machines can produce parts at a rapid rate, significantly reducing production time.

Drawbacks of Plastic Injection Machines:

– Initial investment: The cost of purchasing a plastic injection machine can be substantial, especially for small businesses or individuals.

– Design limitations: While plastic injection machines offer great design flexibility, there are certain limitations, such as draft angles and wall thickness requirements, that need to be considered during the design process.

– Tooling costs: Creating molds for injection molding can be expensive, particularly for complex parts or low-volume production.

Market Trends in Plastic Injection Machines:

– Industry 4.0 integration: With the advent of Industry 4.0, plastic injection machines are becoming more connected and intelligent. Features like real-time monitoring, predictive maintenance, and remote control are becoming increasingly common.

– Sustainability: Manufacturers are now focusing on developing eco-friendly plastic injection machines that reduce energy consumption, waste generation, and environmental impact.

– Miniaturization: There is a growing demand for smaller and more compact plastic injection machines to cater to the needs of industries such as electronics and medical devices.

Injection Mold Testing and Injection Molding Machines:

Injection mold testing is a crucial step in the plastic injection molding process. It involves evaluating the mold design, material flow, cooling time, and other variables to ensure the production of high-quality parts. Injection molding machines play a vital role in this process by precisely injecting the molten plastic into the mold cavity.

If you’re considering purchasing a plastic injection machine, it’s important to understand the different types available in the market. Some popular types include hydraulic machines, electric machines, and hybrid machines. Each type has its own advantages and disadvantages, so it’s essential to choose one that aligns with your specific requirements.

In conclusion, plastic injection machines have revolutionized the manufacturing industry, enabling the production of complex plastic parts with precision and efficiency. In this article, we explored the features, benefits, drawbacks, and market trends of these machines. Whether you’re a professional or a hobbyist, understanding the nuances of plastic injection machines is essential to make an informed decision.

Check the plastic injection machine reviews and explore the world of injection mold testing and injection molding machines. Enhance your manufacturing capabilities and unlock new possibilities with the right plastic injection machine for your needs.

*Check the coil packing solution with leading manufacturer for the professional solution just here:* Plastic Injection Machine

“Ultimate Guide to Injection Mold Testing & Machines: Unbiased Reviews on Plastic Injection Machinery”