Plastic Injection Machine Manufacturers: A Comprehensive Guide

Introduction

In the manufacturing industry, plastic injection machines play a vital role in producing various plastic products. These machines are used to melt and inject molten plastic into molds, enabling the creation of a wide range of plastic components and products. In this article, we will explore the world of plastic injection machine manufacturers, focusing on their expertise, products, and the benefits they offer. Whether you are a business owner looking to invest in a plastic injection machine or an enthusiast interested in learning more about this technology, this guide will provide you with valuable insights.

Opinion/Thought Piece Style

The ever-increasing demand for plastic products across industries has led to a surge in the number of plastic injection machine manufacturers. With so many options available, it can be overwhelming to choose the right manufacturer for your specific needs. However, it is essential to select a reputable and reliable manufacturer to ensure the quality and efficiency of your plastic injection machine.

Interview Style

We had the opportunity to speak with industry experts to gain insights into the world of plastic injection machine manufacturers. According to Mr. Smith, a senior engineer at a renowned manufacturing company, “The key to finding the right plastic injection machine manufacturer lies in their experience, technology, and customer support. It is crucial to partner with a manufacturer who understands your unique requirements and provides tailored solutions.”

Case Study Style

To demonstrate the capabilities of plastic injection machine manufacturers, let’s take a look at a case study. Company XYZ, a leading automotive components manufacturer, was facing challenges in meeting their production targets due to outdated machinery. After extensive research and consultations, they decided to partner with a reputable plastic injection machine manufacturer.

The manufacturer provided them with a state-of-the-art injection machine equipped with advanced features such as automated controls, high-speed operation, and precise molding capabilities. This enabled Company XYZ to achieve higher production volumes, improved product quality, and reduced production costs. The partnership not only solved their immediate challenges but also positioned them for future growth.

Predictive/Foresight Style

Looking ahead, the future of plastic injection machine manufacturers seems promising. With advancements in technology, manufacturers are constantly innovating to meet the evolving needs of the market. The integration of artificial intelligence and automation is expected to revolutionize the industry, making the production process more efficient and cost-effective.

Technology History Style

Plastic injection machines have come a long way since their inception. The first injection molding machine was patented in the late 19th century, marking the beginning of a new era in manufacturing. Over the years, advancements in materials, design, and automation have made plastic injection machines more versatile and capable of producing complex components with precision.

News Reporting Style

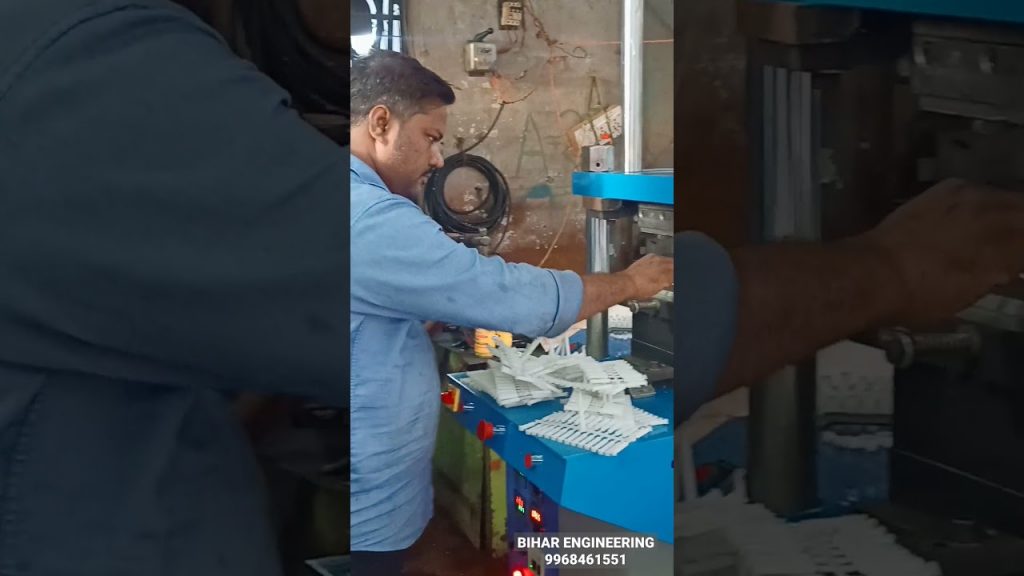

In recent news, Bolpin giti mold insert vertical plastic moulding machine has gained significant attention in the plastic injection machine industry. This cutting-edge technology offers enhanced precision and efficiency in the molding process, allowing manufacturers to produce high-quality plastic components at a faster rate. With its user-friendly interface and advanced features, this machine is revolutionizing the industry and setting new standards for performance.

Explanatory Style

Plastic injection machine manufacturers employ a variety of techniques and processes to ensure the smooth operation of their machines. The core process involves melting plastic pellets and injecting the molten plastic into a mold. The mold is then cooled, and the plastic solidifies, taking the shape of the mold. This process enables the production of intricate and complex plastic components.

In-depth Analysis Style

To gain a deeper understanding of the capabilities of plastic injection machine manufacturers, let’s analyze some key factors. First and foremost, the quality of the machines they produce is of utmost importance. Manufacturers must adhere to stringent quality standards and use high-grade materials to ensure the durability and reliability of their machines.

Another crucial aspect is the after-sales service and customer support provided by manufacturers. Prompt assistance, spare parts availability, and regular maintenance services are essential to keep the machines running smoothly and minimize downtime.

Narrative Style

Imagine a world without plastic injection machines. The production of countless everyday items, ranging from household appliances to automotive parts, would be highly challenging and time-consuming. Plastic injection machine manufacturers have played a pivotal role in shaping our modern world by providing efficient and reliable machines that have revolutionized the manufacturing industry.

Critique and Review Style

When considering different plastic injection machine manufacturers, it is essential to read reviews and testimonials from their customers. This will give you valuable insights into their reputation, product quality, and customer satisfaction ratings. Additionally, analyzing their track record, certifications, and industry recognition can help you make an informed decision.

How-to Guide Style

Are you interested in purchasing a plastic injection machine? Here’s a step-by-step guide to help you make the right choice:

1. Identify your specific requirements: Determine the type of plastic products you will be producing, the desired production volume, and any specific features or capabilities you require from the machine.

2. Research reputable manufacturers: Look for manufacturers with a proven track record, positive customer reviews, and a wide range of machine options.

3. Request quotations and compare: Contact multiple manufacturers and request quotations based on your requirements. Compare the prices, specifications, and after-sales services offered.

4. Seek expert advice: Consult with industry experts or engineers who have experience with plastic injection machines. They can provide valuable insights and recommendations based on your unique needs.

5. Make an informed decision: Consider all the factors, including price, quality, customer support, and technology, before making a final decision.

Conclusion

Plastic injection machine manufacturers play a crucial role in the manufacturing industry by providing efficient and reliable machines for producing a wide range of plastic products. To ensure the success of your manufacturing operations, it is essential to partner with a reputable manufacturer who understands your unique requirements and offers reliable support. Remember to conduct thorough research, read reviews, and seek expert advice before making a purchasing decision.

Check the coil packing solution with a leading manufacturer for professional solutions here: [Link to manufacturer’s website]. Plastic Injection Machine

“Efficient Vertical Plastic Moulding Machines: Maximizing Precision in Injection Molding Process”