Looking for a reliable and efficient way to cut, insert, and shrink heat shrink tubes? Look no further than the automatic heat-shrink tube cutting insertion shrinking machine. This innovative machine supports the simultaneous shrinking of two wire cables, making it a must-have tool for any industry that requires heat shrink tube applications. In this article, we will explore the features and benefits of this machine, as well as its applications and potential impact on various industries.

Heat shrinking machines have revolutionized the way we apply heat shrink tubes. Gone are the days of manually cutting and inserting each tube, wasting time and effort. With the automatic heat-shrink tube cutting insertion shrinking machine, the entire process becomes faster, more precise, and highly efficient.

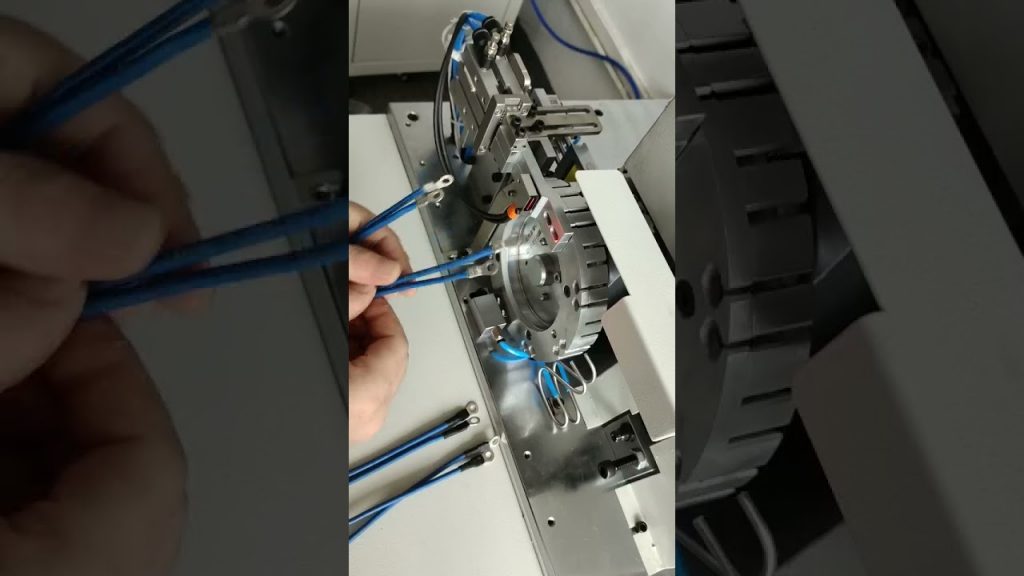

The machine’s cutting mechanism ensures accurate and clean cuts, eliminating the need for manual trimming. This not only saves time but also reduces the chances of errors or inconsistencies in the tube length. The insertion feature allows for easy placement of the tubes onto the cables, ensuring a secure and reliable connection.

One of the standout features of this machine is its ability to support two wire cable shrinking at the same time. This means that you can work on multiple cables simultaneously, significantly increasing productivity and reducing downtime. Whether you are working on a small-scale project or dealing with large volumes of cables, this machine can handle it all.

The automatic heat-shrink tube cutting insertion shrinking machine is designed to be user-friendly and intuitive. Its user interface allows for easy programming and customization, ensuring that even beginners can operate it with ease. Additionally, the machine is equipped with safety features to protect operators from any potential hazards.

The applications of this machine are vast and varied. It is commonly used in industries such as electronics, automotive, telecommunications, and aerospace. Heat shrink tubes are essential for protecting and insulating wires, cables, and other components from environmental factors such as moisture, dust, and heat. With this machine, the process becomes seamless, ensuring a professional and reliable end result.

In addition to its immediate benefits, the automatic heat-shrink tube cutting insertion shrinking machine also offers long-term advantages. Its high-speed operation and consistent performance contribute to increased efficiency and reduced labor costs. Moreover, the precision and accuracy of the machine’s cutting and shrinking process result in higher quality end products.

As industries continue to evolve and demand more advanced technologies, the automatic heat-shrink tube cutting insertion shrinking machine proves to be a valuable asset. Its ability to streamline the heat shrink tube application process makes it an ideal choice for businesses looking to enhance productivity and maintain a competitive edge.

In conclusion, the automatic heat-shrink tube cutting insertion shrinking machine is a game-changer in the heat shrink tube application industry. Its efficient and precise operation, combined with the ability to support two wire cable shrinking simultaneously, makes it a must-have tool for any business dealing with heat shrink tubes. Invest in this machine and experience the benefits of improved productivity and superior quality. Check the coil packing solution with a leading manufacturer for the professional solution just here. Shrinking Machine

“Efficient Heat Shrink Tube Cutting & Inserting Machine: Streamline Your Workflow”