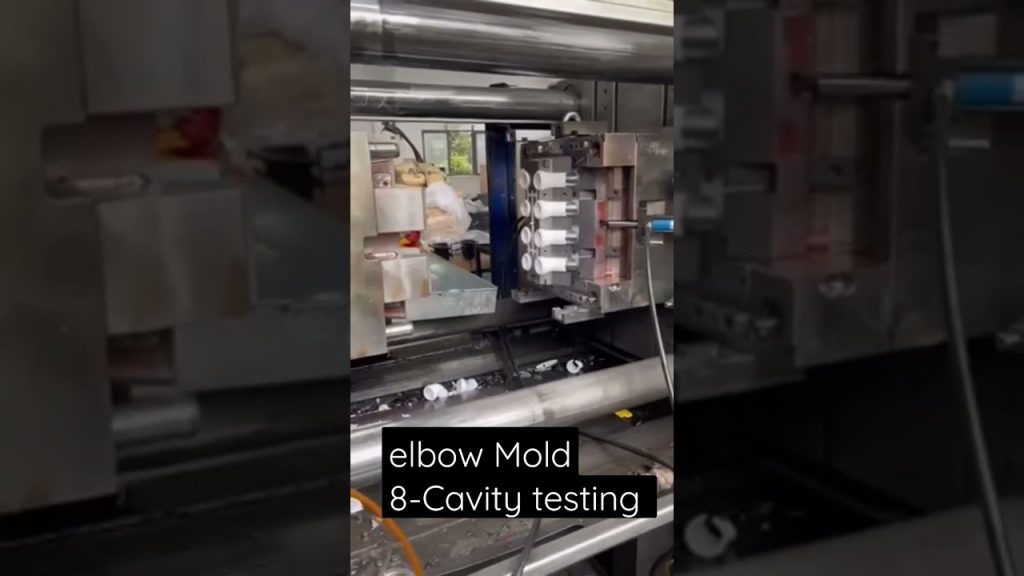

If you’re in the manufacturing industry, chances are you’ve heard of industrial plastic injection machines. These machines are an essential tool in the production of plastic products, allowing manufacturers to create high-quality and precision parts with ease. In this YouTube video, we will be exploring the capabilities of an industrial plastic injection machine and showcasing a test run of an elbow mold with an 8-cavity design.

Before we dive into the details, let’s take a brief look at what an industrial plastic injection machine is. Simply put, it is a device that melts plastic materials and injects them into a mold cavity to create a desired shape. These machines are widely used in various industries, including automotive, electronics, medical, and consumer goods. They offer fast production cycles, high accuracy, and the ability to produce complex designs.

Now, let’s move on to the main focus of this video – the testing of an elbow mold with an 8-cavity design. The purpose of this test is to demonstrate the capabilities of the industrial plastic injection machine and showcase its efficiency in producing multiple parts simultaneously. The 8-cavity design allows for a higher production rate, reducing the overall production time and cost.

During the test, we will be monitoring various parameters such as the injection pressure, temperature, and cycle time. These factors play a crucial role in ensuring the quality and consistency of the injected parts. By showcasing this test, viewers will gain a better understanding of how an industrial plastic injection machine operates and the level of precision it can achieve.

In addition to the testing process, we will also discuss the benefits and advantages of using an industrial plastic injection machine. These include:

1. Cost-effectiveness: By automating the production process, manufacturers can significantly reduce labor costs and improve overall efficiency.

2. Versatility: Industrial plastic injection machines can accommodate a wide range of plastic materials, allowing manufacturers to produce parts with different characteristics and properties.

3. Precision and accuracy: These machines offer high repeatability and precision, ensuring that each part meets the required specifications.

4. Time-saving: With fast production cycles and the ability to produce multiple parts simultaneously, manufacturers can save valuable time and meet tight deadlines.

5. Sustainability: Plastic injection molding is a highly efficient process that minimizes waste and optimizes material usage, making it a sustainable manufacturing solution.

As we wrap up this video, we hope that you’ve gained valuable insights into the capabilities of an industrial plastic injection machine. Whether you’re a manufacturer looking to enhance your production capabilities or a curious individual interested in the manufacturing process, these machines play a crucial role in the industry.

Check out our website for more information on industrial plastic injection machines and other manufacturing solutions. We offer a wide range of products and services to meet your specific needs. Contact us today to discuss your requirements and find the perfect solution for your business.

[Check the coil packing solution with leading manufacturer for the professional solution just here:] Plastic Injection Machine

“Efficient Testing of 8-Cavity Elbow Mold with Injection Molding Machine for Industrial Plastic Injection”