Title: Industrial Labeling Machine for Precise Label Application on Syringe | Arca Labeling & Marking

Description:

Introduction:

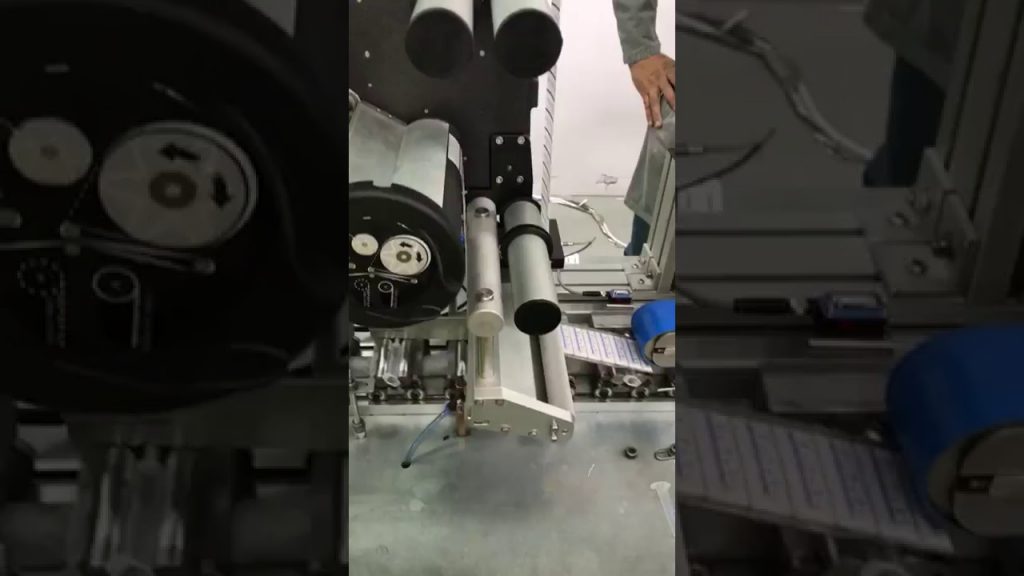

Welcome to our informative video showcasing the efficiency and precision of the Industrial Labeling Machine by Arca Labeling & Marking. In this video, we demonstrate the seamless application of labels on syringes using our advanced industrial labeler. Discover the cutting-edge technology that ensures accurate labeling for various industries.

Video Content:

In this video, we delve into the remarkable features of our Industrial Labeling Machine and its application on syringes. Our labeler is designed to meet the specific labeling requirements of medical and pharmaceutical industries, where precision and adherence are crucial.

Key Points Covered:

1. Unparalleled Labeling Accuracy: Our Industrial Labeling Machine guarantees precise label application, reducing the chances of errors and ensuring consistent branding and product information.

2. Efficient Workflow: We showcase the smooth operation steps of the labeler, highlighting how it seamlessly applies labels on syringes at high speeds, optimizing production efficiency.

3. Customizable Labeling Solutions: Our machine offers flexibility, allowing for various label sizes, shapes, and materials, catering to the specific needs of different industries.

4. Advanced Technology: We discuss the innovative features of our labeling machine, such as automated label placement and adjustable settings, ensuring optimal label placement and alignment.

5. Compliance and Traceability: With the Industrial Labeling Machine, manufacturers can easily meet regulatory requirements, including barcode labeling, batch numbers, expiry dates, and other essential information.

6. Enhanced Product Identification: The precise labeling provided by our machine enables easy identification of products, ensuring efficient inventory management and enhanced traceability.

Key Highlights and Interesting Facts:

– Our Industrial Labeling Machine utilizes state-of-the-art sensors and advanced software algorithms to accurately detect and apply labels on syringes with varying shapes and sizes.

– The machine’s user-friendly interface allows for easy setup and adjustment, minimizing downtime and maximizing productivity.

– By integrating our labeler into your production line, you can significantly reduce labor costs associated with manual labeling processes.

Call to Action:

If you want to optimize your labeling process, improve accuracy, and enhance productivity, subscribe to our channel and stay updated with the latest advancements in industrial labeling technology. Don’t forget to like and share this video with others who can benefit from our state-of-the-art solutions.

Additional Tags and Keywords: Industrial labeling machine, label application, syringe labeling, Arca Labeling & Marking, labeling technology, labeler, precise labeling, labeling solutions, labeling accuracy, efficient workflow, compliance, traceability.

Hashtags: #IndustrialLabelingMachine #SyringeLabeling #LabelApplication #ArcaLabeling #MarkingTechnology #PreciseLabeling

A tilter for label application on a syringe is a device or mechanism that helps in properly aligning and applying labels onto syringes. Here is an example of a tilter for label application on a syringe:

1. The tilter consists of a sturdy base with adjustable arms or holders to securely hold the syringe during the labeling process. The arms can be adjusted to accommodate different sizes of syringes.

2. The tilter is equipped with a motor or actuator that allows controlled tilting or rotation of the syringe. This can be achieved through a simple push-button control or a programmable interface.

3. The tilter has a sensor or positioning mechanism to detect the location of the syringe and align it accurately for label application. This ensures that the label is applied on the desired area of the syringe, such as the barrel or the plunger.

4. The tilter includes a label dispenser or applicator that holds the labels and releases them onto the syringe surface. The label applicator can be designed to apply adhesive labels or use other methods such as heat transfer or laser etching.

5. The tilter may have additional features such as an integrated label printer or a barcode scanner to print and verify labels before application. This ensures accurate labeling and traceability of syringes.

6. The tilter can be designed to work as a standalone unit or be integrated into an automated labeling system. It can be controlled manually or connected to a computerized control system for precise labeling operations.

7. Safety features such as emergency stop buttons and protective enclosures are incorporated to ensure operator safety and prevent accidents during the labeling process.

Overall, the tilter for label application on a syringe provides a reliable and efficient solution for accurately applying labels onto syringes, enhancing product identification, traceability, and compliance with regulatory requirements.Labeling Machine

#Label #Application #Syringe