Are you in the automotive industry and looking for efficient and reliable solutions for dashboard injection molding? Look no further! In this YouTube video, we will explore the world of automotive dashboard injection molding and its connection to plastic injection molding, large mold manufacturing, and mold technology. Whether you are a manufacturer or an enthusiast, this video will provide valuable insights into the process and benefits of using an industrial plastic injection machine.

Dashboard injection molding plays a crucial role in the automotive industry. It involves the production of high-quality plastic dashboards that are not only visually appealing but also durable and functional. To achieve this, manufacturers rely on plastic injection molding, a widely used manufacturing process that allows for the mass production of complex plastic parts.

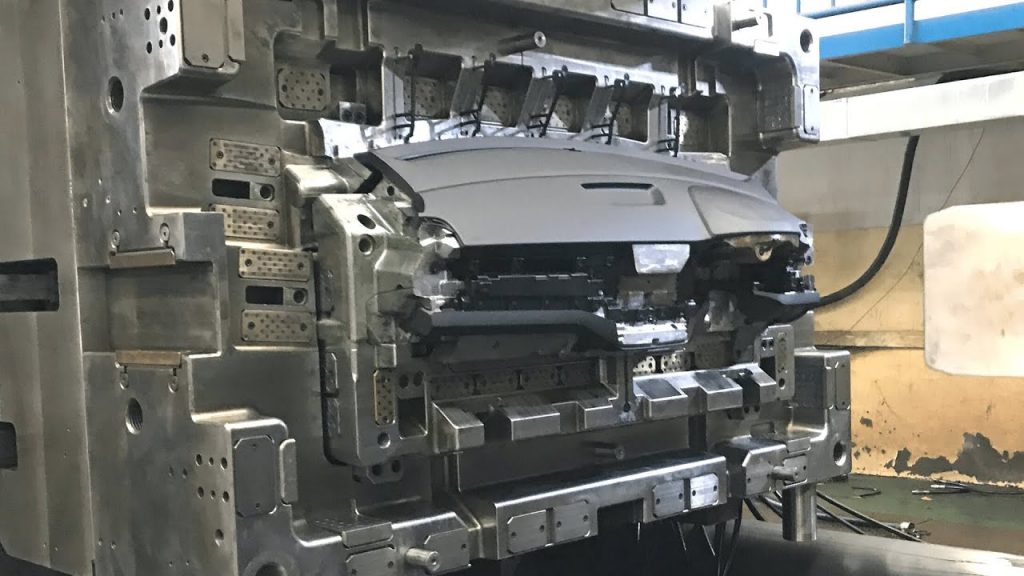

Large mold manufacturing is an integral part of the dashboard injection molding process. The creation of molds requires precision engineering and expertise to ensure accurate and consistent production. By utilizing advanced technologies and techniques, manufacturers can produce molds that meet the exact specifications of the dashboard design.

An industrial plastic injection machine is the heart of the dashboard injection molding process. This machine is responsible for melting the plastic material and injecting it into the mold cavity. With its high-speed and high-pressure capabilities, an industrial plastic injection machine ensures efficient and precise molding of the dashboard components.

Now, let’s delve deeper into the benefits of using an industrial plastic injection machine for dashboard injection molding:

1. Cost-effectiveness: Industrial plastic injection machines allow for high-volume production, reducing the overall cost per part. This makes it an economically viable solution for manufacturing dashboards in large quantities.

2. Time efficiency: The high-speed capabilities of an industrial plastic injection machine enable rapid production cycles, resulting in shorter lead times. This is crucial in meeting the demands of the automotive industry, where time-to-market is critical.

3. Design flexibility: With an industrial plastic injection machine, manufacturers have the freedom to create intricate and complex dashboard designs. This flexibility opens up opportunities for innovative and visually appealing dashboards that enhance the overall aesthetics of vehicles.

4. Consistency and quality: Industrial plastic injection machines ensure consistent and precise molding, leading to high-quality dashboard components. The machines offer tight control over temperature, pressure, and other variables, resulting in uniform part dimensions and superior surface finishes.

To summarize, dashboard injection molding, plastic injection molding, large mold manufacturing, and mold technology are interconnected processes that rely on the capabilities of an industrial plastic injection machine. By utilizing this advanced machinery, manufacturers can achieve cost-effective, time-efficient, and high-quality production of automotive dashboards.

Check out the video to learn more about the fascinating world of automotive dashboard injection molding. Discover how an industrial plastic injection machine can revolutionize your manufacturing process and elevate the quality of your dashboard components. Don’t miss out on this opportunity to stay ahead in the automotive industry!

[Insert YouTube video link here]

Remember, when it comes to dashboard injection molding, industrial plastic injection machines are the key to success. Invest in the right machinery and unlock the full potential of your manufacturing process. Plastic Injection Machine

“Streamlining Automotive Dashboard Manufacturing with Advanced Injection Molding Techniques for Large Mold Production and Industrial Plastic Injection Machines”