Title: “Master the Art of Pallet Wrapping with the Best Pallet Stretch Wrapping Machine”

Description:

Welcome to our comprehensive video on pallet wrapping machines and the advanced Pallet Stretch Wrapping Machine by BOSS Packaging Solutions Pvt Ltd, a leading manufacturer of cutting-edge packaging machinery. In this video, we will delve into the intricate details of pallet wrapping, providing you with valuable insights and knowledge to optimize your packaging process.

Introduction:

Discover the ultimate solution for efficient and secure pallet wrapping with the Pallet Stretch Wrapping Machine. This video offers a comprehensive overview of the machine’s features, benefits, and operation, equipping you with the necessary information to make an informed decision.

Video Content:

1. Understanding Pallet Wrapping: Gain a deep understanding of the importance of pallet wrapping and its impact on product safety and stability during transport. Learn about the challenges faced in traditional manual wrapping methods and how the Pallet Stretch Wrapping Machine revolutionizes the process.

2. Key Features and Benefits: Explore the advanced features and cutting-edge technology incorporated into the Pallet Stretch Wrapping Machine. From adjustable wrapping tension to customizable wrapping patterns, discover how this machine ensures optimal load containment and protection.

3. Step-by-Step Operation: Follow our step-by-step guide to operating the Pallet Stretch Wrapping Machine effortlessly. Learn how to set up the machine, adjust parameters, and ensure consistent and uniform wrapping. Maximize efficiency and productivity with this user-friendly machine.

4. Safety and Reliability: Discover the safety measures implemented in the Pallet Stretch Wrapping Machine, ensuring operator well-being and minimizing potential risks. We prioritize reliability and durability, providing you with a long-lasting and dependable solution for your packaging needs.

Call to Action:

If you found this video informative and insightful, we encourage you to like, subscribe, and share it with others in your industry. Stay updated with the latest advancements in packaging machinery by subscribing to our channel for future content.

Additional Tags and Keywords: pallet wrapping machine, Pallet Stretch Wrapping Machine, packaging machinery, pallet wrapping, secure load containment, efficient packaging, automated packaging solutions, pallet wrapping technology

Hashtags: #PalletWrappingMachine #StretchWrapping #PackagingMachinery #BOSSPackagingSolutions #EfficientPackaging

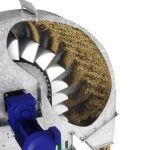

A tilter for a Pallet Stretch Wrapping Machine is a device that is used to tilt the pallet before wrapping it with stretch film. It helps to improve the stability and security of the pallet load by ensuring that the load is evenly distributed and properly aligned.

Here is a basic outline for a tilter for a Pallet Stretch Wrapping Machine:

1. Design the tilter frame: Start by designing a sturdy frame that can hold the weight of the pallet and the load. The frame should be made from durable materials such as steel to ensure its strength and stability.

2. Install a tilting mechanism: The tilting mechanism can be hydraulic, pneumatic, or mechanical, depending on the specific requirements of the machine. This mechanism should be designed to smoothly and securely tilt the pallet to the desired angle.

3. Add safety features: Incorporate safety features such as sensors and emergency stop buttons to ensure the protection of the operators and prevent accidents. These safety features should be integrated into the control system of the tilter.

4. Integrate with the Stretch Wrapping Machine: Connect the tilter to the existing Pallet Stretch Wrapping Machine. This can be done by designing the tilter in such a way that it can be easily attached and detached from the machine.

5. Test the tilter: Before deploying the tilter for regular use, conduct thorough testing to ensure its functionality, stability, and safety. Test the tilting mechanism under different load conditions to ensure its reliability and accuracy.

6. Provide user-friendly controls: Design user-friendly controls for the tilter, allowing operators to easily adjust the tilt angle and activate the tilting mechanism. These controls should be intuitive and clearly labeled to avoid any confusion.

7. Install and train operators: Once the tilter passes all the necessary tests, install it in the Pallet Stretch Wrapping Machine and provide training to the operators on how to use it safely and effectively.

Remember to consult with experts in the field of Pallet Stretch Wrapping Machines and tilters to ensure that the design and functionality of your specific tilter meet industry standards and requirements. pallet wrapping machine

#Pallet #Stretch #Wrapping #Machine