Title: Collaborative Robotic Pallet Cell with Integrated Semi Automatic Pallet Stretch Wrapper

Description:

Introduction:

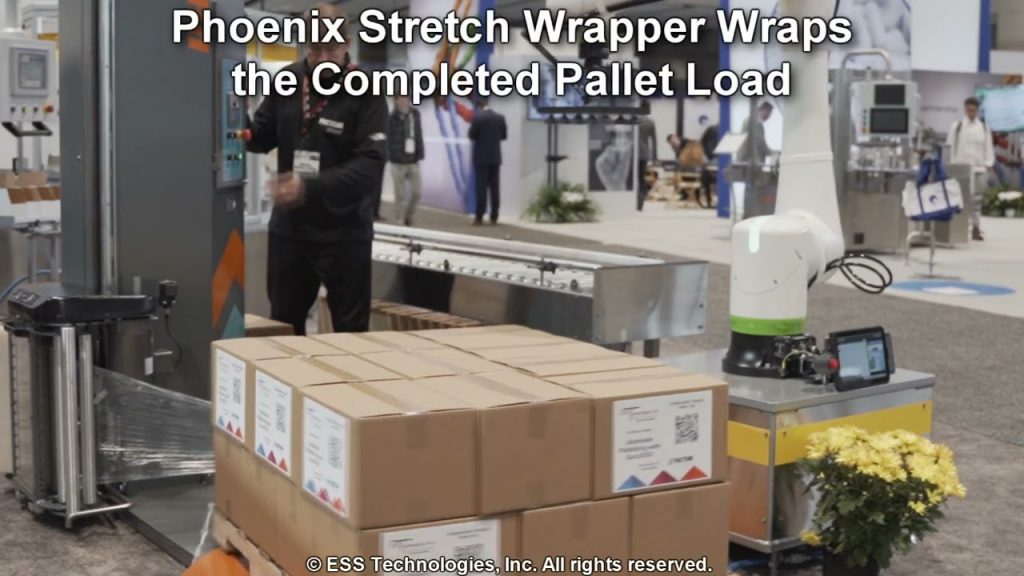

Welcome to our video showcasing the innovative Collaborative Robotic Pallet Cell with Integrated Semi Automatic Pallet Stretch Wrapper. In this video, we will explore how ESS Technologies has seamlessly integrated the FANUC CRX-25iA collaborative robot with a vacuum end effector, resulting in a compact and efficient pallet cell solution.

Video Content:

Our video provides an in-depth look at the features and benefits of this advanced pallet stretch wrapper system. We will highlight the key points and walk you through the operation steps, ensuring you gain a comprehensive understanding of its capabilities.

1. Overview of the Collaborative Robotic Pallet Cell:

Discover how this cutting-edge technology combines the power of a collaborative robot with a vacuum end effector to achieve optimal pallet wrapping efficiency. We will delve into its compact design, which allows for seamless integration into any production line.

2. Semi Automatic Pallet Stretch Wrapper Integration:

Learn about the integrated semi-automatic pallet stretch wrapper, a key component of the pallet cell. We will explain its functions, including the stretching and wrapping process, ensuring secure and stable pallet loads.

3. Key Features and Benefits:

Explore the various features and benefits of this system, such as its high-speed operation, precision wrapping, and user-friendly interface. We will discuss how it improves productivity, reduces labor costs, and enhances safety in your warehouse or manufacturing facility.

4. Operation Steps:

Follow along as we demonstrate the step-by-step operation of the Collaborative Robotic Pallet Cell. From loading the pallet to initiating the wrapping process, we will guide you through each stage, highlighting important details to ensure optimal performance.

Call to Action:

If you found this video informative and valuable, we encourage you to like, subscribe, and share it with others who may benefit from this innovative pallet stretch wrapping solution. Join our community and stay updated on the latest advancements in industrial automation.

Additional Tags and Keywords:

Pallet stretch wrapper, Collaborative robotic pallet cell, Semi-automatic pallet stretch wrapper, FANUC CRX-25iA, Vacuum end effector, Compact pallet cell, Warehouse automation, Manufacturing efficiency, Pallet wrapping system, Industrial robotics.

Hashtags:

#palletstretchwrapper #collaborativeroboticpalletcell #semiautomaticstretchwrapper #FANUCCRX25iA #vacuumendeffector #compactoroboticsolution #warehouseautomation #manufacturingefficiency #palletwrappingsystem #industrialrobotics

A tilter for a Collaborative Robotic Pallet Cell with Integrated Semi Automatic Pallet Stretch Wrapper is a software program that controls the tilting function of the collaborative robotic pallet cell and coordinates it with the semi automatic pallet stretch wrapper. The purpose of the tilter is to automate the process of tilting pallets and wrapping them with stretch film, increasing efficiency and reducing the need for manual labor.

The tilter software program would have the following features:

1. User interface: The tilter would have a user-friendly interface that allows operators to easily input the necessary parameters for tilting and wrapping pallets. This could include the pallet dimensions, desired tilt angle, and wrapping requirements.

2. Tilting control: The tilter would control the collaborative robot’s tilting function, allowing it to safely and accurately tilt pallets to the desired angle. The software would ensure that the tilting is done within the specified limits to prevent any damage or accidents.

3. Wrapping coordination: The tilter would coordinate with the semi automatic pallet stretch wrapper to ensure that the wrapping process starts immediately after the pallet has been tilted to the desired angle. This would prevent any delay between the two processes and optimize the overall efficiency of the system.

4. Safety features: The tilter would incorporate safety features to ensure the well-being of operators and prevent any accidents. This may include sensors that detect the presence of operators near the robotic pallet cell and automatically pause or stop the tilting process if necessary.

5. Error detection and handling: The tilter would have built-in error detection mechanisms to identify any issues during the tilting or wrapping process. It would provide appropriate error messages or alerts to operators and suggest corrective actions to resolve the problem.

6. Logging and reporting: The tilter would log important information such as the number of pallets tilted, wrapping time, and any errors encountered. This data could be used for performance analysis, troubleshooting, and optimization of the system.

Overall, a tilter for a Collaborative Robotic Pallet Cell with Integrated Semi Automatic Pallet Stretch Wrapper would streamline the process of tilting and wrapping pallets, improving efficiency and reducing the need for manual labor. pallet stretch wrpaper

#Collaborative #Robotic #Pallet #Cell #Integrated #Semi #Automatic #Pallet #Stretch #Wrapper