Check out our website for the best coil packing solution from the leading manufacturer in the industry.

Title: Enhancing Efficiency with Automatic Plastic Injection Machines

Introduction:

In today’s rapidly evolving manufacturing industry, efficiency and precision are paramount. With the advancement of technology, automatic plastic injection machines have emerged as a game-changer, revolutionizing the way plastic products are manufactured. In this article, we will delve into the intricacies of automatic plastic injection machines and explore how they have transformed the manufacturing process.

I. Understanding Automatic Plastic Injection Machines

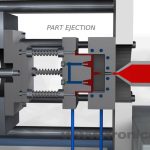

Automatic plastic injection machines are powerful tools that enable the mass production of plastic products. These machines utilize advanced technology and innovative techniques to precisely mold plastic materials into desired shapes and sizes. The fully automated process ensures consistent and high-quality outputs, reducing human error and optimizing productivity.

II. The Benefits of Automatic Plastic Injection Machines

1. Increased Efficiency: Automatic plastic injection machines significantly enhance production speed and efficiency. With their ability to rapidly mold plastic materials, these machines can meet high-volume demands without compromising quality. This efficiency translates into cost savings and improved profitability for manufacturers.

2. Precision and Consistency: The automated nature of these machines ensures precise and consistent results. The injection process is carefully controlled, allowing for the creation of intricate designs and complex shapes with minimal variation. This level of precision is crucial in industries such as automotive, electronics, and medical, where strict quality standards must be met.

3. Reduced Labor Costs: By automating the plastic injection process, manufacturers can reduce their reliance on manual labor. This not only cuts down on labor costs but also eliminates the risk of human error. Automatic plastic injection machines can operate continuously, maximizing production output and minimizing downtime.

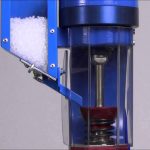

III. Full Automatic Vertical Plastic Molding Machine Screw Type

One notable type of automatic plastic injection machine is the full automatic vertical plastic molding machine with a screw-type mechanism. This machine boasts a capacity of 100 grams and is widely used in various industries. Its vertical design allows for efficient use of space, making it suitable for factories with limited floor space.

IV. Case Study: Aligarh Plastic Manufacturing Factory

To illustrate the effectiveness of automatic plastic injection machines, let’s take a look at a case study from Aligarh, India. A plastic manufacturing factory in Aligarh recently adopted the use of automatic plastic injection machines, and the results were astounding. The factory experienced a significant increase in production output, reduced rejection rates, and improved overall product quality. The implementation of these machines also led to a reduction in labor costs, as fewer workers were needed to operate the production line.

V. Conclusion

Automatic plastic injection machines have revolutionized the manufacturing industry, offering increased efficiency, precision, and cost savings. With their ability to meet high-volume demands while maintaining consistent quality, these machines have become an indispensable tool for manufacturers worldwide. By embracing the power of automation, companies can stay competitive in today’s fast-paced business landscape.

Check the coil packing solution with the leading manufacturer for a professional solution on our website. Plastic Injection Machine

“Efficient and Versatile Vertical Plastic Molding Machine for 100g Capacity: Aligarh’s Reliable Solution”