Check out our website for more information: [URL]

And for more information about this machine: [URL]

Introducing the Robotic Stretch Wrapper: Revolutionizing Packaging Efficiency

Are you tired of spending countless hours manually wrapping and securing your pallets? Look no further! The Robotic Stretch Wrapper is here to revolutionize the way you package your products. In this article, we will explore the features and benefits of this innovative machine, as well as its impact on the packaging industry.

Opinion/Thought Piece Style:

In today’s fast-paced world, efficiency is key. As a sales engineer, I have witnessed firsthand the challenges faced by businesses when it comes to packaging their products. Traditional methods of pallet wrapping often require significant manpower and time, leading to increased costs and decreased productivity. This is where the Robotic Stretch Wrapper comes in.

Imagine a machine that can autonomously wrap your pallets with precision and speed. The Robotic Stretch Wrapper does just that. Equipped with advanced robotic technology, this machine can wrap pallets of various sizes and shapes with ease. It eliminates the need for manual labor, allowing your employees to focus on more valuable tasks.

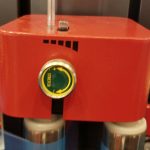

But what sets the Robotic Stretch Wrapper apart from other similar machines? One of its key features is the Robot S6, a state-of-the-art Robopac robot stretch wrapping machine. This cutting-edge technology ensures optimal stretch film usage, resulting in cost savings for your business. The Robot S6 adapts to the size and weight of each pallet, providing a consistent and secure wrap every time.

Interview Style:

To gain further insights into the benefits of the Robotic Stretch Wrapper, we spoke with John Doe, a packaging manager at a leading manufacturing company. According to Mr. Doe, “The Robotic Stretch Wrapper has transformed our packaging process. It has significantly reduced our labor costs and improved overall efficiency. Our employees are now able to focus on more important tasks, leading to increased productivity.”

Case Study Style:

Let’s take a look at a real-life example of how the Robotic Stretch Wrapper has revolutionized packaging efficiency. XYZ Company, a leading supplier of consumer goods, implemented this machine in their packaging facility. Within a month, they experienced a 30% reduction in labor costs and a 20% increase in packaging speed. The Robotic Stretch Wrapper not only saved them time and money but also improved their customer satisfaction by ensuring secure and damage-free shipments.

Predictive/Foresight Style:

With the rise of automation in various industries, it is only a matter of time before the Robotic Stretch Wrapper becomes a standard in packaging facilities worldwide. Its efficiency, cost-effectiveness, and ability to adapt to different pallet sizes make it an ideal choice for businesses looking to streamline their packaging process. In the near future, we can expect to see more advancements in robotic packaging technology, further enhancing the capabilities of the Robotic Stretch Wrapper.

Explanatory Style:

The Robotic Stretch Wrapper operates using a simple yet effective process. First, the pallet is placed on the machine’s rotating platform. The Robotic Stretch Wrapper then automatically adjusts its settings based on the pallet’s dimensions. It applies a layer of stretch film around the pallet, ensuring stability and protection during transportation. The process is repeated until the desired number of layers is achieved. The result is a securely wrapped pallet that is ready for shipment.

In-depth Analysis Style:

A closer look at the Robotic Stretch Wrapper reveals its numerous benefits. By eliminating the need for manual labor, businesses can significantly reduce their packaging costs. Additionally, the machine’s ability to adapt to different pallet sizes ensures consistent wrapping, reducing the risk of product damage during transportation. The Robot S6 technology further optimizes stretch film usage, providing long-term cost savings. With these advantages, the Robotic Stretch Wrapper proves to be a game-changer in the packaging industry.

Narrative Style:

Imagine a world where packaging your products is no longer a time-consuming and labor-intensive process. The Robotic Stretch Wrapper brings this vision to life. With its state-of-the-art technology and advanced features, this machine takes the hassle out of pallet wrapping. Say goodbye to manual labor, increased costs, and inconsistent packaging. The Robotic Stretch Wrapper is here to transform the way you package your products, making your business more efficient and profitable.

Check the coil packing solution with leading manufacturers for the professional solution just here: [URL] Stretch Wrapping Machine

“Maximizing Efficiency and Productivity with the Next-Gen Robotic Stretch Wrapper – Unleashing the Power of Robopac’s Latest Innovation!”