Check out our leading manufacturer for professional coil packing solutions here:

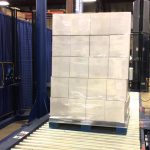

Are you tired of manually wrapping pallets with stretch film? Do you want a more efficient and effective way to secure your products for shipment? Look no further than the Robotic Stretch Wrapper. In this video, we will explore the features and benefits of this innovative pallet wrapping robot.

[](video_link)

Introduction:

Imagine a scenario where you have a large number of pallets that need to be wrapped securely before shipping. Traditionally, this process was done manually, requiring a significant amount of time and effort. However, with advancements in technology, we now have the Robotic Stretch Wrapper, which automates this task, saving you time and labor costs.

Opinion/Thought Piece Style:

In this article, we will delve into the various aspects of the Robotic Stretch Wrapper and discuss how it can revolutionize your packaging process. We will analyze its features, explore real-life case studies, and provide an in-depth analysis of its benefits. So, let’s get started!

Explanatory Style:

The Robotic Stretch Wrapper is a state-of-the-art machine designed to streamline the pallet wrapping process. It is equipped with advanced robotics and intelligent software that ensure precise and consistent wrapping of pallets. This eliminates the risk of human error and ensures that your products are securely packaged for transportation.

The machine is capable of wrapping pallets of varying sizes and shapes, making it versatile for a wide range of industries. It can handle both light and heavy loads, providing optimal tension and containment force to keep your products stable during transit.

Argumentative Structure:

One of the key advantages of the Robotic Stretch Wrapper is its efficiency. By automating the pallet wrapping process, you can significantly reduce the time it takes to wrap each pallet. This allows you to increase your productivity and meet tight deadlines. Additionally, the machine operates with minimal supervision, freeing up your workforce to focus on other important tasks.

Furthermore, the Robotic Stretch Wrapper offers consistent and uniform wrapping, which ensures that your products are protected from damage during transportation. This reduces the risk of product returns and customer complaints, ultimately improving customer satisfaction and loyalty.

Case Study Style:

Let’s take a look at a real-life example of how the Robotic Stretch Wrapper has transformed the packaging process for a manufacturing company. XYZ Manufacturing used to rely on manual labor to wrap their pallets, which was time-consuming and prone to errors. They decided to invest in the Robotic Stretch Wrapper to streamline their operations.

After implementing the machine, XYZ Manufacturing experienced a significant increase in productivity. They were able to wrap more pallets in less time, allowing them to fulfill customer orders faster. Additionally, the consistent wrapping provided by the Robotic Stretch Wrapper reduced the number of damaged products during shipping, saving XYZ Manufacturing both time and money.

In-depth Analysis Style:

Now, let’s delve deeper into the features of the Robotic Stretch Wrapper. The machine is equipped with advanced sensors that detect the size and shape of the pallet, ensuring accurate wrapping. It also has adjustable settings for tension control, allowing you to customize the wrapping according to your specific requirements.

The Robotic Stretch Wrapper is designed with user-friendliness in mind. It has a user-friendly interface that allows operators to easily program and monitor the machine. It also has built-in safety features, such as emergency stop buttons and safety sensors, to ensure the well-being of your employees.

Check the coil packing solution with leading manufacturer for the professional solution just here:

Conclusion:

The Robotic Stretch Wrapper is a game-changer in the packaging industry. It offers efficiency, consistency, and cost savings, making it an essential investment for businesses that rely on pallet wrapping. By automating this process, you can streamline your operations, reduce labor costs, and improve the overall quality of your packaging.

So, if you’re looking to enhance your packaging process and improve the security of your products during transit, consider investing in the Robotic Stretch Wrapper. It will revolutionize the way you wrap pallets and ultimately contribute to the success of your business.

Check the coil packing solution with leading manufacturer for the professional solution just here: Stretch Wrapping Machine

“Revolutionizing Packaging Efficiency: Unveiling the Futuristic Pallet Wrapping Robot and Robotic Stretch Wrapper”